Nov . 29, 2024 17:46 Back to list

Suppliers and Manufacturers of Differential Pressure Gauges for Various Applications

Understanding Differential Pressure Gauges and Choosing the Right Supplier

In various industries, from oil and gas to pharmaceuticals, accurate measurements are crucial for process control and monitoring. One of the key instruments used for measuring pressure differences is the differential pressure gauge. This integral piece of equipment not only helps ensure the safety and efficiency of processes but also significantly contributes to maintaining product quality. With a wide range of applications, selecting the right supplier and manufacturer for differential pressure gauges becomes paramount for businesses looking to optimize their operations.

What is a Differential Pressure Gauge?

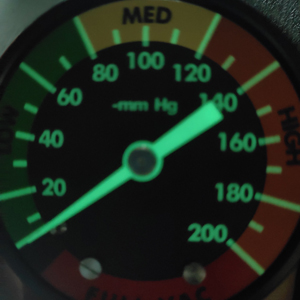

A differential pressure gauge is a device that measures the difference in pressure between two points in a system. This pressure difference can indicate fluid flow, filter conditions, level measurements, and more. The gauge typically has two ports one connected to the high-pressure side and the other to the low-pressure side. The reading obtained from this gauge can help engineers and operators recognize trends or anomalies in their systems.

Differential pressure gauges can come in various designs, including mechanical and electronic types, each with its advantages depending on the application. Mechanical gauges may use a Bourdon tube or diaphragm, while electronic gauges often employ sensors that provide a digital readout and may be connected to control systems for automated monitoring.

Applications and Importance

Differential pressure gauges are essential in numerous applications 1. Industrial Processes In manufacturing settings, these gauges help monitor pressure drops across filters, ensuring optimized performance and timely maintenance. 2. Water Treatment Differential pressure readings can indicate the condition of filtration systems and help maintain water quality. 3. HVAC Systems In heating, ventilation, and air conditioning (HVAC), these gauges monitor air flow and filter status, crucial for system efficiency and occupant comfort. 4. Pharmaceuticals and Food Processing In these industries, maintaining sterile conditions is vital, and differential pressure gauges help monitor critical processes.

Given their importance, choosing the right differential pressure gauge supplier can influence every aspect of your operation.

Selecting the Right Supplier

differential pressure gauge supplier manufacturers

When looking for a differential pressure gauge supplier, consider the following factors

1. Product Range and Customization Different applications might require specific types of gauges. Look for suppliers who offer a variety of products and customizable solutions tailored to your specific needs.

2. Quality and Certification Quality is non-negotiable when it comes to instrumentation. Suppliers should adhere to international standards and certifications, ensuring their products meet the rigorous demands of your industry.

3. Expertise and Support The best suppliers will offer not only products but also technical support. Look for companies with knowledgeable staff who can provide guidance on product selection, installation, and troubleshooting.

4. Reputation and Reliability Research potential suppliers’ reputations by reading reviews and seeking recommendations from other professionals in your industry. A reliable supplier will have a proven track record of delivering quality products and prompt customer service.

5. Pricing and Terms While price shouldn’t be the only factor, it’s essential to ensure you’re getting a fair deal. Compare prices among suppliers but consider the total cost of ownership, including maintenance and potential downtime.

6. Warranty and Support A solid warranty and responsive customer service indicate that the manufacturer stands behind their product, providing peace of mind as you integrate their gauges into your system.

Conclusion

Differential pressure gauges play an indispensable role across various sectors, facilitating the efficient and safe operation of systems. Selecting the right supplier is critical, as it impacts not only the quality of the gauges you receive but also the support and services that accompany them. By carefully assessing potential suppliers based on the factors outlined above, businesses can ensure they partner with a reputable manufacturer, setting the stage for operational excellence. Proper monitoring and measurement of differential pressure ultimately lead to improved productivity, enhanced safety, and higher-quality products in any industrial application.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025