Dec . 23, 2024 00:33 Back to list

Exporters of Diaphragm Seal Differential Pressure Gauges for Accurate Measurements

Understanding Differential Pressure Gauges with Diaphragm Seals A Focus on Export Markets

Differential pressure gauges are crucial instruments used in various industrial applications to measure the difference in pressure between two points within a system. These devices are essential for monitoring flow rates, ensuring system efficiency, and maintaining safety in processes involving gases and liquids. When it comes to applications in harsh environments, differential pressure gauges with diaphragm seals are increasingly favored by industries due to their robustness and reliability. This article explores the significance and features of these specialized gauges, especially concerning the export market.

What is a Differential Pressure Gauge with a Diaphragm Seal?

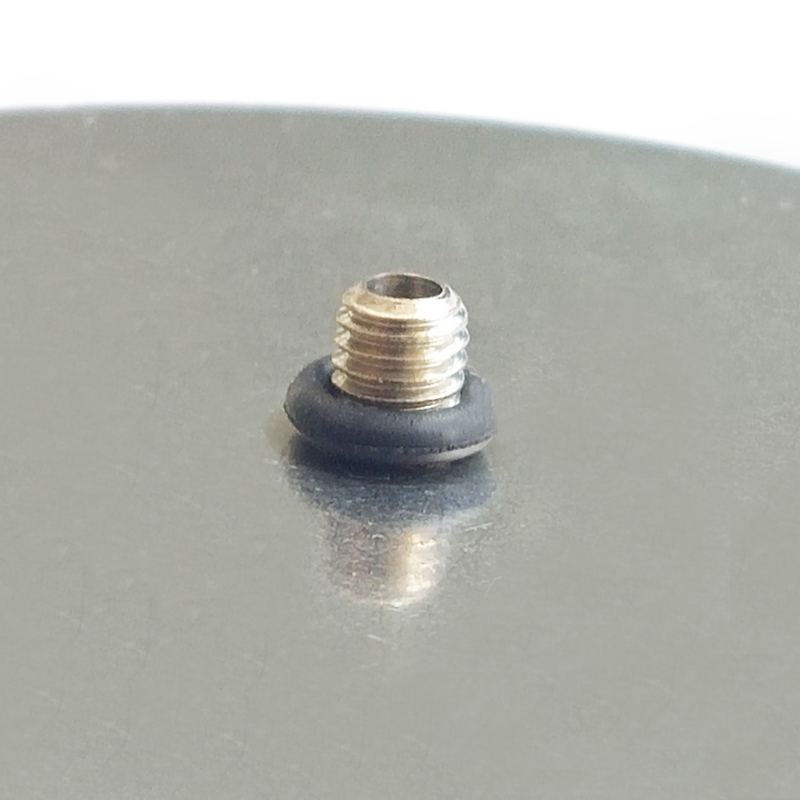

A differential pressure gauge with a diaphragm seal incorporates a flexible diaphragm that separates the measuring element from the medium being measured. This design not only protects the gauge from corrosive or viscous fluids but also allows for accurate readings even in challenging conditions. The diaphragm responds to pressure differences, thereby enabling the gauge to deliver precise measurements without direct contact with the fluid. This versatility makes them suitable for a wide range of applications, including chemical processing, water treatment, oil and gas, and food and beverage industries.

Benefits of Using Diaphragm Seals

1. Protection Against Corrosion One of the most critical advantages of diaphragm seals is that they protect the measurement instrument from corrosive substances, preventing damage and extending the lifespan of the equipment.

2. Prevention of Clogging In applications where the media might contain particulates or other viscous fluids, the diaphragm seal helps reduce the risk of clogging that would typically impair traditional gauges.

4. Versatility in Applications These gauges are suitable for a variety of applications, including high-pressure systems and extreme temperatures, making them ideal for exports to regions with demanding industrial processes.

differential pressure gauge with diaphragm seal exporters

The Export Market for Differential Pressure Gauges

With the global industrial landscape continually evolving, the demand for differential pressure gauges with diaphragm seals has expanded significantly. Exporters are capitalizing on this trend, supplying these essential tools to a broad array of markets hailing from various engineering sectors. Some of the key factors driving the export market include

- Increasing Industrialization As countries, especially in Asia and Africa, industrialize rapidly, the demand for advanced measurement instruments, such as differential pressure gauges, is on the rise.

- Focus on Process Safety Industries are increasingly prioritizing safety and efficiency, which propels the need for accurate measurement tools. Diaphragm-sealed gauges play a vital role in maintaining safety standards in hazardous environments.

- Technological Advancements Continuous advancements in materials and technology have improved the performance of these gauges, making them more appealing for export, particularly to countries aiming to enhance their industrial capabilities.

- Regulatory Compliance Many regions enforce strict regulations for environmental safety and process efficiency, which can only be met with reliable measurement technologies.

Conclusion

Differential pressure gauges with diaphragm seals represent a compelling solution for industries aiming for accuracy, safety, and durability in their operations. The export market for these instruments is poised for growth, driven by global industrialization and an increasing emphasis on maintaining high safety and regulatory standards. As exporters continue to meet the diverse needs of various industries, the role of these specialized gauges will remain indispensable in the quest for operational excellence across the globe. With their unique advantages, it is clear that differential pressure gauges with diaphragm seals are not just instruments but vital tools for progress in modern industry.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025