Nov . 05, 2024 23:21 Back to list

explain diaphragm pressure gauge manufacturer

Understanding Diaphragm Pressure Gauges An Overview of Their Manufacturing

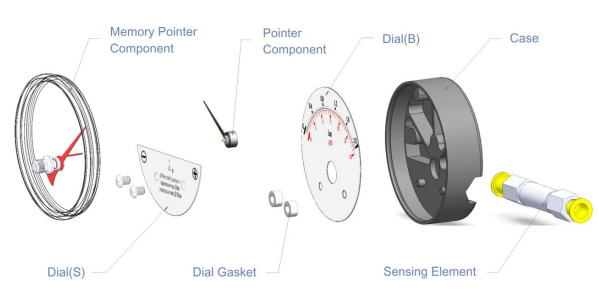

Diaphragm pressure gauges are crucial instruments used across various industries for measuring the pressure of gases and liquids. Their reliability and accuracy make them fundamental in applications ranging from HVAC systems to industrial manufacturing. This article delves into the intricacies of diaphragm pressure gauge manufacturing, shedding light on the construction, working principle, and advantages of these essential devices.

The diaphragm pressure gauge operates based on the deflection of a flexible diaphragm, which is positioned within the gauge. When pressure is applied, the diaphragm bends, converting the pressure into a mechanical movement. This movement is then transferred to a pointer on a dial or an electronic display, indicating the pressure level. The simplicity of this design underlies its effectiveness and accuracy.

Manufacturers of diaphragm pressure gauges focus on several critical factors to ensure product reliability. The choice of materials is paramount. Typically, the diaphragm is made from high-quality stainless steel or other corrosion-resistant alloys, which are instrumental in enhancing the gauge's durability, especially in hostile environments. These materials are selected based on the type of media being measured; for instance, corrosive substances may require specialized coatings or materials to prevent degradation.

Moreover, the design of the diaphragm itself significantly impacts performance. Engineers employ advanced simulation techniques to optimize the shape and thickness of the diaphragm, ensuring a precise response to varying pressure levels. The manufacturing process often involves intricate machining and fabrication techniques, which demand high levels of precision to meet strict standards.

explain diaphragm pressure gauge manufacturer

Quality assurance is another essential facet of diaphragm pressure gauge manufacturing. Manufacturers implement rigorous testing protocols to ensure that every gauge can withstand the operational conditions it will face. This includes dynamic testing under real-world conditions to assess how the gauge responds to fluctuating pressures.

In addition to mechanical gauges, many manufacturers are now venturing into electronic diaphragm pressure gauges. These innovative devices incorporate digital technology, offering enhanced features such as data logging, remote monitoring capabilities, and integration with digital control systems. The shift towards electronic gauges reflects a broader trend in industrial automation and the increasing demand for smart instrumentation.

Choosing a reputable diaphragm pressure gauge manufacturer is vital for ensuring product quality and performance. Companies with a strong reputation in the industry often provide a robust selection of gauges to fit various applications and can offer customized solutions based on specific client needs. Furthermore, a good manufacturer will often provide excellent after-sales support, ensuring that clients receive the necessary maintenance and calibration services.

In conclusion, diaphragm pressure gauges are versatile and reliable instruments relevant to numerous industries. Their manufacturing process, characterized by the selection of materials, meticulous design engineering, and stringent quality control, is crucial in producing gauges that meet the demands of various applications. As technology evolves, the future holds exciting opportunities for advancements in diaphragm pressure gauge designs, contributing further to industrial efficiency and safety.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025