Jul . 29, 2024 22:52 Back to list

Explore the Range of Minihelic Differential Pressure Gauge Solutions for Precision Measurement Needs

Understanding Minihelic Differential Pressure Gauge Products

In today's industrial landscape, precise measurement techniques are critical for efficient operations. Among the various tools available for monitoring pressure differentials, the Minihelic differential pressure gauge stands out for its reliability and versatility. This article highlights what Minihelic differential pressure gauges are, their applications, features, and advantages, and why they are essential in various industries.

What is a Minihelic Differential Pressure Gauge?

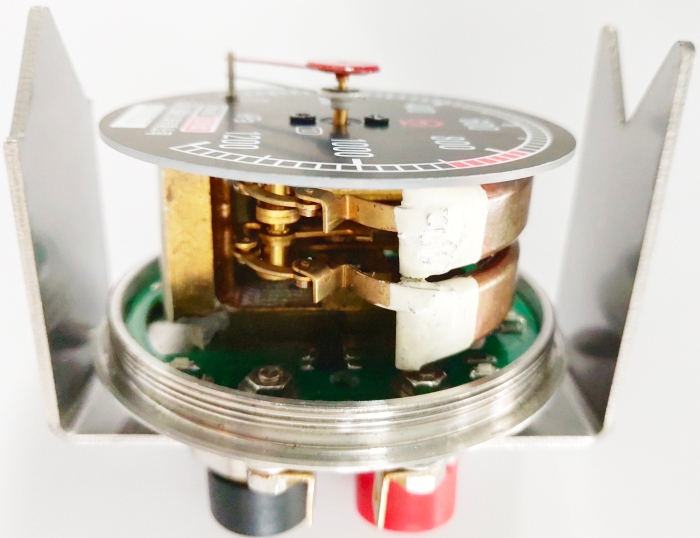

A Minihelic differential pressure gauge is a sensitive measurement instrument designed to gauge the difference in pressure between two points. Utilizing a lightweight, compact design, this gauge is capable of measuring low to moderate pressure differentials with high accuracy. The Minihelic gauge typically employs a mechanical mechanism with a flexible diaphragm, which reacts to variations in pressure and translates these changes into a readable display.

Key Features

1. Compact Design The Minihelic gauge is designed to occupy minimal space, making it ideal for applications where space is limited. Its small form factor allows easy installation even in tight areas.

2. Ease of Use With simple operational mechanics and intuitive readings, these gauges are user-friendly, allowing operators to quickly assess pressure levels without requiring extensive training.

3. Wide Measurement Range Minihelic gauges can measure differential pressures typically ranging from 0-1 in w.c. (inches of water column) up to several inches, catering to diverse applications across various sectors.

4. Durability Constructed from robust materials, Minihelic gauges can withstand the rigors of industrial environments. They are resistant to dust, moisture, and vibrations, ensuring a longer lifespan and reliable performance.

5. Calibration and Accuracy These gauges are calibrated for high accuracy and can provide real-time data. Regular calibration checks ensure continued precision in measurements, which is critical for process control.

Applications

Minihelic differential pressure gauges are employed in a plethora of applications across different industries. Some of the prominent uses include

minihelic differential pressure gauge products

- HVAC Systems In heating, ventilation, and air conditioning (HVAC) systems, Minihelic gauges are commonly used to monitor filter pressure drops, ensuring optimal air flow and efficiency.

- Clean Room Environments Maintaining specific pressure levels is crucial in clean room settings. Minihelic gauges help ensure that the pressure differentials maintain the necessary cleanliness standards by detecting leaks and irregularities.

- Process Control Many manufacturing processes require the monitoring of pressure levels to prevent equipment failure. Minihelic gauges provide valuable data to ensure operational safety and efficiency.

- Laboratories and Pharmaceutical Facilities In laboratories and pharmaceutical settings, where maintaining sterile environments is critical, Minihelic gauges help monitor pressure conditions to ensure compliance with health regulations.

Advantages of Minihelic Gauges

The Minihelic differential pressure gauge offers several advantages that make it a preferred choice for many industries

- Cost-Effectiveness Compared to electronic pressure sensors, Minihelic gauges are generally more affordable while providing reliable performance and durability.

- No Need for External Power Being a mechanical device, Minihelic gauges do not require an external power source, reducing operational costs and simplifying installations.

- Versatility Their compact and durable design makes them suitable for a broad range of applications, from commercial buildings to heavy industrial settings.

Conclusion

Minihelic differential pressure gauges represent a crucial tool in the arsenal of pressure measurement instruments. With their compact design, ease of use, and wide range of applications, they effectively meet the demands for accurate pressure monitoring in various industries. As businesses increasingly focus on process efficiency and compliance with safety standards, the importance of reliable measuring instruments like the Minihelic gauge cannot be overstated. Whether in an HVAC system or a clean room environment, these gauges ensure effective pressure management, facilitating smooth and safe operations in any industrial setup.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025