Oct . 31, 2024 13:58 Back to list

Innovative Bourdon Type Differential Pressure Gauge for Accurate Measurement Solutions

The Bourdon type differential pressure gauge is a vital instrument widely used in various industrial applications to measure pressure differences between two points. Its design and functionality are rooted in the principles of fluid mechanics and mechanical engineering, making it not only a common choice for engineers but also a reliable tool in numerous sectors, including oil and gas, water treatment, and HVAC systems.

First invented in the mid-19th century by the French engineer Eugène Bourdon, this innovative gauge consists of a curved, sealed tube that expands when pressure is applied. The degree of expansion correlates directly with the pressure difference between two locations. In the case of a differential pressure gauge, two Bourdon tubes may be used, or a single tube may be connected to two different pressure sources, allowing for precise measurement of the difference.

The mechanism operates on the simple principle that as pressure is applied to one end of the tube, it attempts to straighten out. This movement is transmitted to a pointer, which moves across a calibrated dial, providing a clear reading of the pressure difference. The construction of the Bourdon tube provides a robust and durable method for pressure measurement, capable of withstanding harsh environmental conditions, making it suitable for a wide range of applications.

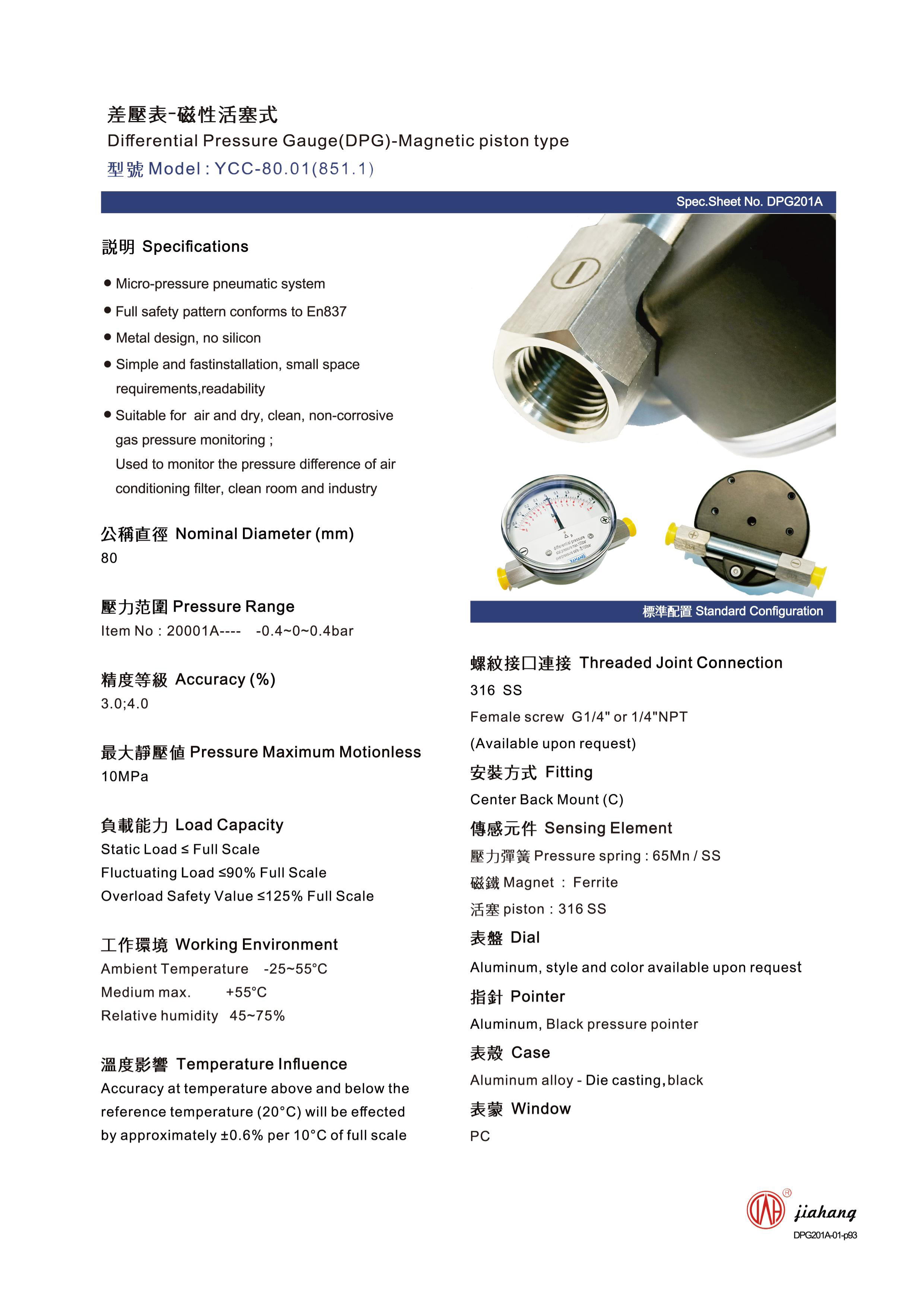

famous bourdon type differential pressure gauge

One of the significant advantages of the Bourdon type differential pressure gauge is its mechanical simplicity, which results in high reliability and minimal maintenance requirements

. Unlike electronic devices, these gauges do not rely on batteries or power sources, making them ideal for remote locations or environments where power supply is intermittent. Furthermore, they can be designed to withstand extreme temperatures and pressures, enhancing their versatility.In practical applications, these gauges are crucial in monitoring processes such as fluid flow, filtration, and even HVAC operations, where maintaining specific pressure differentials is essential for efficiency and safety. By providing real-time feedback on pressure changes, they enable operators to make informed decisions, ensuring optimal system performance and preventing potential failures.

Despite the emergence of digital and electronic alternatives, the Bourdon type differential pressure gauge remains a favorite in the industry. Its accuracy, durability, and ease of use make it an invaluable tool for engineers and technicians alike. As industries continue to advance, the fundamental design and reliability of the Bourdon gauge ensure its place in future applications, proving that sometimes, the simplest solutions are the most effective.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025