Dec . 22, 2024 19:11 Back to list

High-Performance Differential Pressure Gauge for Precision Measurement in Demanding Applications

Understanding Famous High Pressure Differential Pressure Gauges

In various industrial applications, the accurate measurement of pressure is critical. Among the numerous instruments used for this purpose, high pressure differential pressure gauges stand out as essential tools, ensuring the safe and efficient operation of various systems. These gauges play a vital role in processes ranging from oil and gas production to water treatment facilities, where monitoring pressure differences can prevent equipment failure and improve operational efficiency.

What is a Differential Pressure Gauge?

A differential pressure gauge measures the difference in pressure between two points in a system. This type of gauge is crucial in applications where understanding the pressure drop across filters, pumps, or other components is necessary to determine their efficiency and operational health. High pressure differential gauges specifically cater to environments where the pressures involved are significantly above atmospheric levels, requiring specialized materials and designs to withstand extreme conditions.

Working Principle

The operation of a differential pressure gauge is based on the principles of fluid mechanics. It typically employs a diaphragm, Bourdon tube, or a capacitive sensor to detect pressure changes. When pressure is applied to either side of the diaphragm, it flexes in response to the difference in pressure, creating a readable output on the gauge. This output can be in the form of an analog needle or a digital display, depending on the model.

High pressure differential gauges are particularly designed to manage the rigors of high-pressure environments. They often feature robust construction to handle severe conditions while maintaining accuracy and reliability. Specialized materials like stainless steel and advanced sealing technologies are commonly used to enhance their resistance to corrosive substances and extreme temperatures.

Applications of High Pressure Differential Pressure Gauges

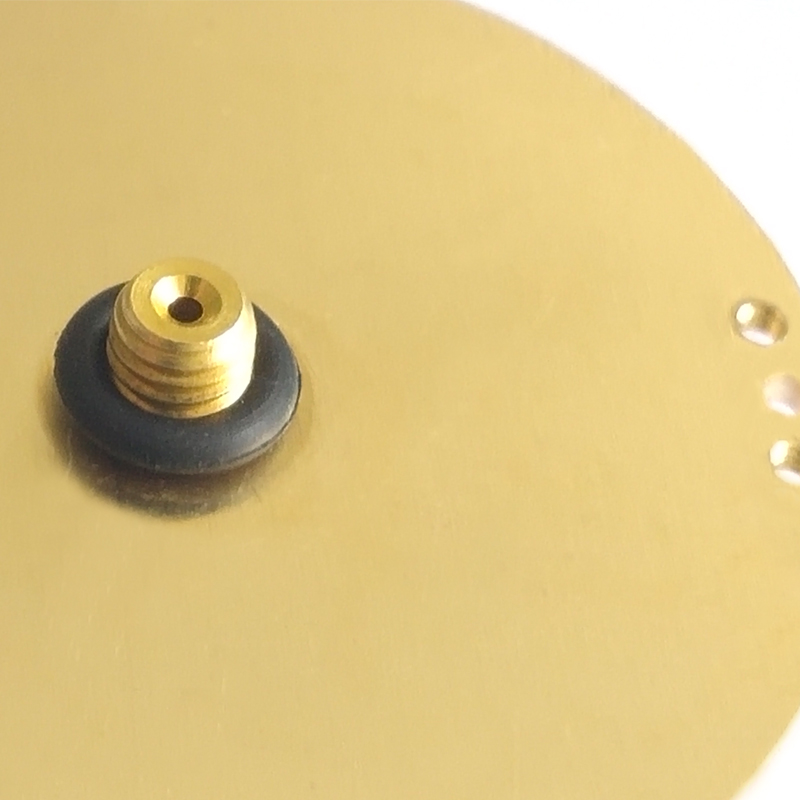

famous high pressure differential pressure gauge

2. Water Treatment Plants These gauges help monitor the flow and pressure in water treatment systems, allowing operators to adjust processes to maintain water quality and comply with regulations.

3. HVAC Systems High pressure differential gauges are integral in heating, ventilation, and air conditioning systems, where they monitor airflow and ensure systems operate efficiently.

4. Pharmaceutical Manufacturing In the pharmaceutical industry, precise pressure monitoring is crucial for maintaining sterile environments and ensuring product safety and efficacy.

5. Chemical Processing These gauges are used to measure pressure differences in reactors and other chemical processing equipment, helping to control reactions and ensure safety.

Advantages of Using High Pressure Differential Pressure Gauges

- Accuracy High pressure differential gauges provide precise measurements, which are essential for efficient process control. - Durability Designed to withstand extreme conditions, these gauges are built to last, minimizing the need for replacements and maintenance. - Versatility They can be used in a variety of settings, making them suitable for multiple industries and applications. - Improved Safety Continuous monitoring of pressure differences helps identify potential issues before they escalate, contributing to a safer work environment.

Conclusion

High pressure differential pressure gauges are indispensable instruments in many industrial processes. Their ability to accurately measure pressure differences directly impacts operational efficiency, safety, and cost-effectiveness. As technology advances, we can expect even more sophisticated gauges that offer enhanced features and improved accuracy, paving the way for smarter industrial processes. The continued evolution of these instruments will be essential, especially as industries face increasing demands for efficiency and sustainability in their operations. For businesses relying on high-pressure systems, investing in reliable high pressure differential pressure gauges is not merely a choice but a necessity for success in today's competitive landscape.

-

Precision Differential Pressure Gauge Assembly Reliable & Customizable Solutions

NewsMay.29,2025

-

WIKA Sanitary Diaphragm Pressure Gauge High Precision & Durability

NewsMay.29,2025

-

HD Fire Pressure Gauges High Accuracy & Durable Solutions

NewsMay.28,2025

-

Custom Singles Capsule Systems Top Exporters & Factories

NewsMay.28,2025

-

Piston-Style Differential Pressure Gauges Precision & Durability

NewsMay.28,2025

-

WIKA Differential Pressure Gauge 700.04 High-Accuracy Industrial Measurement

NewsMay.28,2025