Nov . 24, 2024 18:50 Back to list

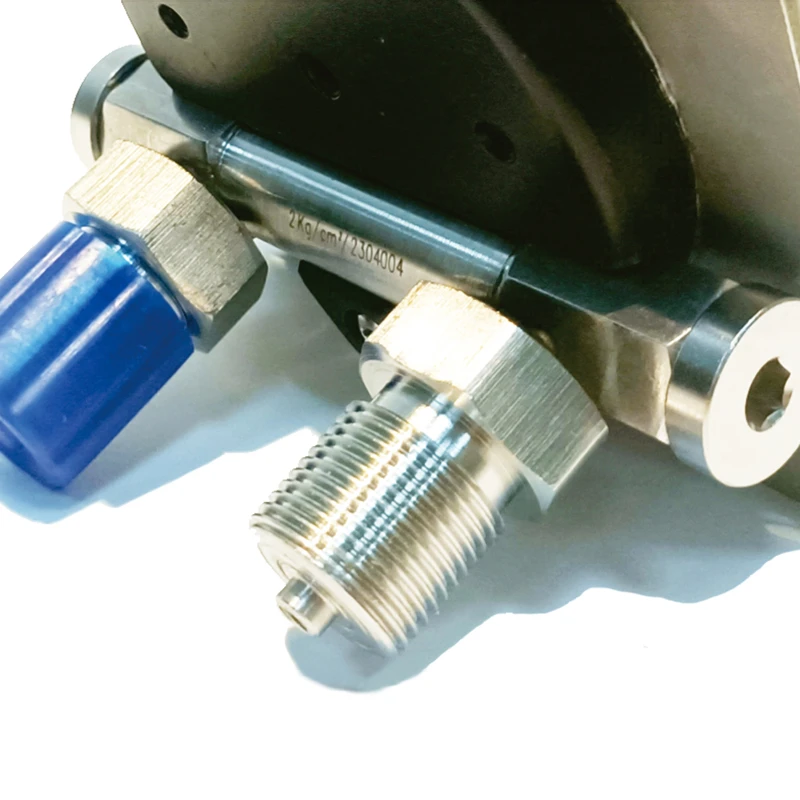

famous micro differential pressure gauge

Understanding the Famous Micro Differential Pressure Gauge

In the realm of industrial instrumentation, accurate pressure measurement is crucial for the optimal functioning of many systems. One of the pivotal devices in this area is the micro differential pressure gauge. This instrument is not just a tool but a cornerstone technology used in various applications, including HVAC systems, clean rooms, pharmaceutical manufacturing, and more.

What is a Micro Differential Pressure Gauge?

A micro differential pressure gauge is designed to measure the pressure difference between two points in a system. Unlike standard pressure gauges that measure absolute pressure or gauge pressure relative to atmospheric pressure, differential pressure gauges provide a comparison—typically between an outlet and an inlet or between two points of the same system. This capability allows for enhanced monitoring and control of processes where precise pressure management is necessary.

Often, these gauges are characterized by their ability to detect extremely small pressure differential changes, often in the range of a few Pascals. This sensitivity makes them particularly useful in applications where even slight variations can indicate a significant issue or change in state.

Applications

The applications of micro differential pressure gauges are diverse. In the HVAC industry, they are used to monitor air filter conditions, ensuring that systems work efficiently and that air quality remains high. When air filters become dirty, the pressure drop across the filter increases, enabling maintenance teams to perform timely replacements.

In clean room environments, maintaining controlled pressure differentials is paramount. Micro differential pressure gauges help ensure that contamination from adjacent areas is minimized by monitoring and adjusting airflow. Similarly, in the pharmaceutical industry, these gauges play a critical role in operational safety and product integrity by monitoring pressure differences in containment systems, sterile environments, and across bioreactors.

Key Features and Benefits

famous micro differential pressure gauge

1. High Sensitivity One of the defining features of micro differential pressure gauges is their high sensitivity. This characteristic allows users to detect and respond to minute changes, which is invaluable in sensitive environments like laboratories and clean rooms.

2. Compact Design Most modern micro differential pressure gauges have a compact design, making them easy to integrate into existing systems without requiring significant modifications. This space-saving design is particularly advantageous in applications with limited installation space.

3. Digital Readouts and Connectivity Many newer models come equipped with digital displays and connectivity options, allowing for easy integration with broader monitoring systems. This feature affords users the ability to log data over time, analyze trends, and optimize processes based on real-time data.

4. Durability These gauges are built to withstand harsh industrial environments, making them reliable for long term use. This resilience is crucial in applications with potential fluctuations in temperature, humidity, or exposure to corrosive substances.

Challenges and Considerations

While micro differential pressure gauges offer numerous benefits, they also present challenges. The installation must be done correctly to ensure accurate readings; misaligned or improperly connected gauges can lead to erroneous measurements. Additionally, regular calibration is essential to maintain accuracy, especially in demanding applications.

Moreover, users must consider the medium being measured. Different fluids and gases have unique characteristics, which can affect pressure readings and the choice of gauge. Understanding these factors is critical when selecting the appropriate gauge for a specific application.

Conclusion

In summary, the micro differential pressure gauge stands as a fundamental tool in modern industrial measurement. Its ability to accurately and sensitively monitor pressure differences plays a critical role in ensuring the efficiency, safety, and reliability of countless processes across various industries. As technology continues to evolve, these instruments will undoubtedly become even more integral to maintaining operational excellence in an increasingly complex industrial landscape. Whether you are an engineer, technician, or decision-maker, understanding and utilizing this technology can significantly enhance your operations.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025