Dec . 25, 2024 02:47 Back to list

Fire Engine Pressure Gauge Manufacturer and Supplier Solutions for Optimal Performance

Understanding Fire Engine Pressure Gauge Factories

Fire safety is a critical concern in modern society, and one of the most essential components of firefighting equipment is the pressure gauge found on fire engines. These gauges play a vital role in ensuring that firefighters have the necessary information to operate their equipment effectively and safely. This article will explore the importance of fire engine pressure gauge factories, their manufacturing processes, and the impact they have on firefighting efforts.

The Importance of Pressure Gauges in Firefighting

Pressure gauges serve as indicators of the hydraulic pressure in firefighting pumps and hoses. They allow firefighters to monitor whether their equipment is functioning correctly and whether the water supply is sufficient to combat fires effectively. If the pressure drops too low, it could compromise the efficacy of firefighting efforts, placing both firefighters and civilians in danger. Therefore, the reliability and accuracy of pressure gauges are paramount in emergency situations.

Manufacturing Process of Pressure Gauges

Fire engine pressure gauges are manufactured in specialized factories equipped with advanced technology and stringent quality control measures. The manufacturing process involves several stages

1. Design and Engineering The first step is comprehensive design work. Engineers utilize computer-aided design (CAD) software to create precise specifications for the pressure gauges. Factors such as the required pressure range, materials, and durability standards are considered to ensure that the end product meets the rigorous demands of firefighting environments.

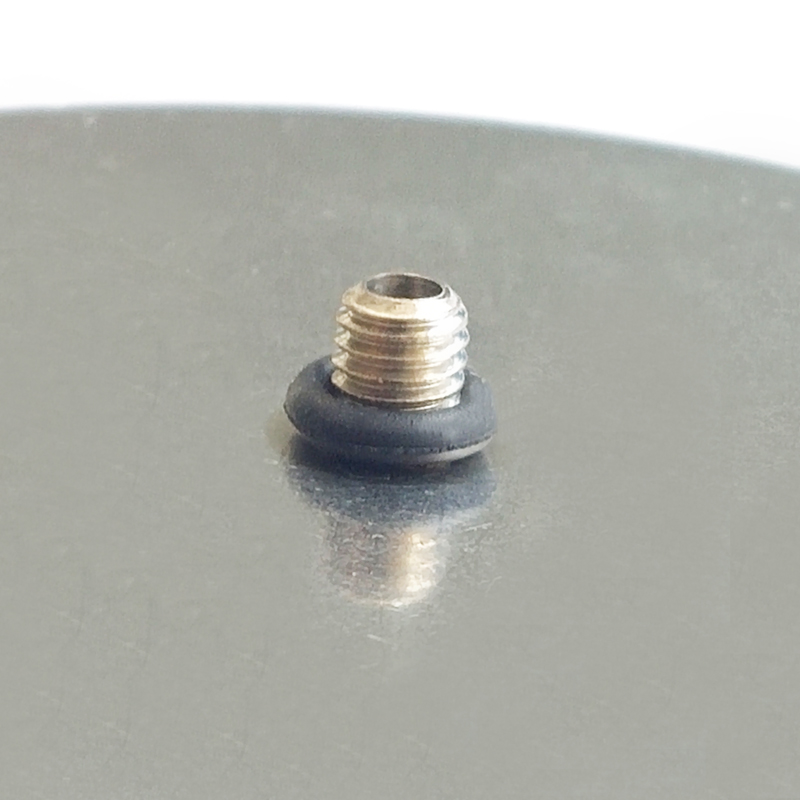

2. Material Selection The materials used in pressure gauge manufacturing must withstand extreme conditions. Common materials include stainless steel, brass, and various plastics. These materials are chosen for their resistance to corrosion, heat, and mechanical stress. The selection process is crucial, as it directly influences the gauge's lifespan and reliability.

3. Machining and Fabrication Once the design and materials are finalized, the components of the pressure gauges are machined and fabricated. Precision engineering is utilized to create the various parts, including the casing, dial, and internal mechanisms. Computer numerical control (CNC) machines are often employed to ensure accuracy and consistency during this phase.

fire engine pressure gauge factory

4. Assembly After fabrication, the various components are brought together for assembly. This process requires skilled technicians who meticulously put together the pieces, ensuring that each gauge functions correctly. Calibration is a vital part of this step, as it ensures that the gauges provide accurate readings across their pressure range.

5. Quality Control After assembly, each pressure gauge undergoes rigorous testing and quality control measures. This includes pressure testing to check for leaks, accuracy checks to verify pressure readings, and durability assessments to ensure the gauge can withstand the rigors of firefighting. Only gauges that pass these tests are approved for distribution.

6. Packaging and Distribution Once the gauges pass quality control, they are carefully packaged to protect them during transportation. Manufacturers then distribute the gauges to fire departments and equipment suppliers, ensuring that they reach the end-users who rely on them during emergencies.

The Impact on Firefighting Efforts

The role of pressure gauge factories in the fire safety ecosystem cannot be overstated. By producing reliable, high-quality pressure gauges, these factories contribute directly to the effectiveness of firefighting operations. Accurate pressure readings enhance situational awareness, allowing firefighters to make informed decisions during emergencies. This can lead to faster response times, improved tactics, and ultimately, more successful outcomes in saving lives and property.

Moreover, the ongoing advancements in technology and materials science are continuously improving the design and functionality of pressure gauges. Innovations such as digital pressure displays and wireless monitoring systems are making it easier for firefighters to access real-time data, further enhancing their operational efficiency.

Conclusion

Fire engine pressure gauge factories play a crucial role in ensuring the safety and effectiveness of firefighting operations. Through meticulous manufacturing processes and stringent quality control, these factories provide the reliable tools that firefighters depend on in life-threatening situations. As technology evolves, the importance of these gauges will only increase, ensuring that firefighting professionals are equipped to face the challenges of today and tomorrow. Through collaboration and innovation, the future of fire safety looks brighter, helping to protect communities from the devastating effects of fires.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025