Nov . 04, 2024 14:49 Back to list

Manufacturers of Flush Diaphragm Pressure Gauges for Accurate Pressure Measurement Solutions

Understanding Flush Diaphragm Pressure Gauges A Comprehensive Overview of Manufacturers

Flush diaphragm pressure gauges are specialized instruments designed for measuring pressure in applications where the medium being measured could clog traditional pressure sensing devices. These gauges are essential in various industries, including pharmaceuticals, food and beverage, chemical processing, and water treatment. In this article, we will delve into the intricacies of flush diaphragm pressure gauges, their applications, and the key manufacturers leading the market.

What Are Flush Diaphragm Pressure Gauges?

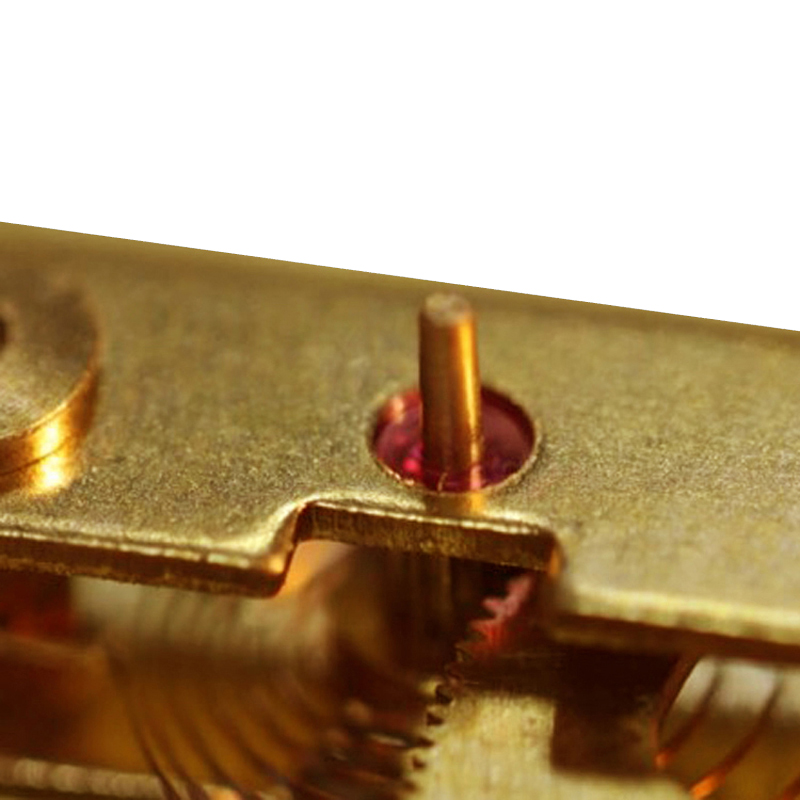

Flush diaphragm pressure gauges utilize a flexible membrane (the diaphragm) that separates the measuring chamber from the process fluid. This design allows for direct contact with the process medium while maintaining an internal pressure measurement system. The flush design is particularly advantageous in applications where viscous, crystallizing, or dirty liquids could obstruct the sensing element of traditional gauges.

Key Features of Flush Diaphragm Pressure Gauges

1. Clog-Resistant Design The flush diaphragm prevents deposits from building up on the pressure sensing element, ensuring accurate and reliable readings over time.

2. Sanitary Options Many flush diaphragm gauges are designed to meet stringent hygiene standards, making them suitable for sanitary applications in the food and pharmaceutical industries.

3. Variety of Materials Manufacturers offer these gauges in various materials, such as stainless steel, to withstand corrosive environments.

4. Wide Measurement Range Flush diaphragm pressure gauges can measure a broad range of pressures, accommodating different process requirements.

5. Customization Many manufacturers provide options for customization, allowing users to select specific connections, scaling, and electrical outputs according to their unique applications.

Applications of Flush Diaphragm Pressure Gauges

Due to their unique design and functionality, flush diaphragm pressure gauges find extensive applications in several industries

- Pharmaceuticals They are used for monitoring pressure in processes where sterility is crucial, ensuring the safety and efficacy of products

.flush diaphragm pressure gauge manufacturers

- Food and Beverage These gauges help maintain hygiene standards by preventing contamination during the measurement of liquids.

- Chemical Processing Flush diaphragm gauges are essential in handling toxic or viscous chemicals, providing accurate pressure readings without the risk of clogging.

- Water Treatment In wastewater management, these gauges monitor the pressure of sludge and other challenging fluids without blockages.

Leading Manufacturers

Several manufacturers are renowned for their high-quality flush diaphragm pressure gauges. Here are a few key players in the industry

1. Wika Instruments Wika is a leading manufacturer known for its extensive range of pressure measurement solutions, including flush diaphragm gauges. They offer a variety of options tailored for specific applications, ensuring high accuracy and reliability.

2. Ashcroft Ashcroft has a long-standing reputation for producing durable and precise pressure instruments. Their flush diaphragm gauges are designed for harsh environments and are suitable for a wide range of industries.

3. Omega Engineering Known for their innovative solutions, Omega offers a broad selection of flush diaphragm pressure gauges with customizable features suited for diverse applications.

4. Danfoss Danfoss specializes in pressure and temperature measurement solutions, providing flush diaphragm gauges that meet stringent industry standards, particularly in the refrigeration and HVAC sectors.

5. Ametek Ametek's powerful brand portfolio includes precision instruments offering flush diaphragm options suitable for both industrial and laboratory settings.

Conclusion

Flush diaphragm pressure gauges play a pivotal role in ensuring accurate pressure measurement in challenging applications. With several leading manufacturers providing innovative solutions, industries have access to reliable instruments tailored to their specific needs. By understanding the benefits and features of these gauges, businesses can make informed decisions to enhance process efficiency and safety.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025