Feb . 18, 2025 12:34 Back to list

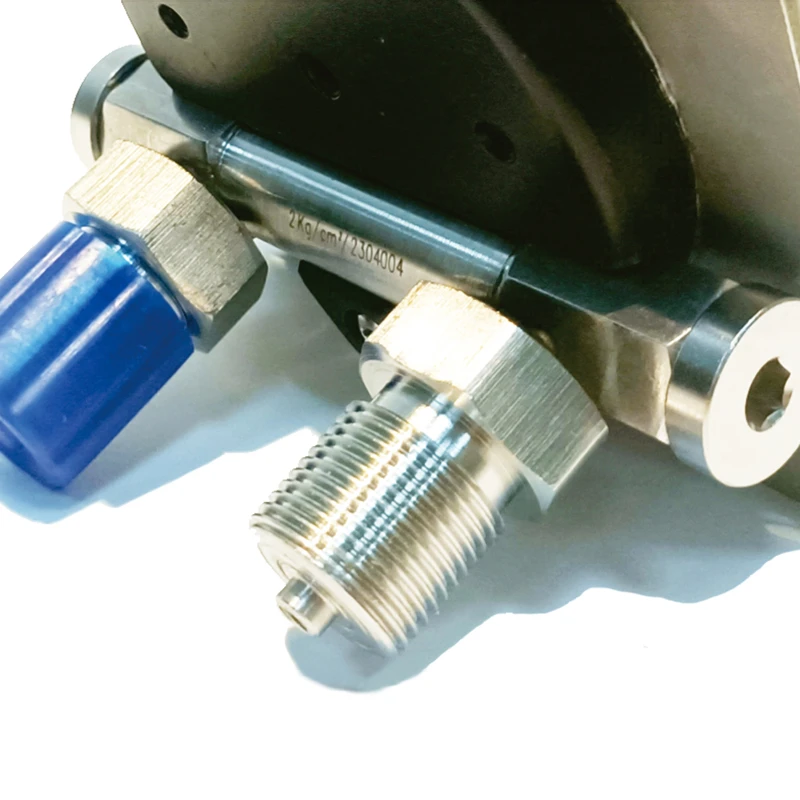

Differential Pressure Gauge-Magnetic piston typeYCC-80.01(851.1)

For industries where precision plays a pivotal role, the application of the high-quality analogue differential pressure gauge stands out as a quintessential tool. These devices, known for their reliability and accuracy, are indispensable in various sectors including oil and gas, manufacturing, and chemical processing. Their primary function is to measure the difference in pressure between two points within a system, offering real-time data that informs crucial operational decisions.

Authoritative figures in instrumentation technology often emphasize the importance of selecting a gauge that provides consistent accuracy. A high-quality analogue differential pressure gauge is meticulously engineered to offer precise measurements, with negligible deviation over extended periods. This consistency is paramount for sectors where minute pressure changes can have profound implications on safety and product quality. Manufacturers carry out rigorous testing to ensure that each gauge meets stringent industry standards, thus bolstering their credibility and bolstering user trust. In terms of expertise, professionals in various industries acknowledge the critical role these devices play in maintaining operational efficiency. Energy companies, for instance, rely on these gauges to monitor and regulate pressure in pipelines and storage facilities, preventing leaks and ensuring compliance with safety standards. Likewise, in chemical plants, analogue differential pressure gauges monitor reaction systems to maintain optimal conditions, safeguarding both personnel and equipment from hazardous events. Experience shared by industry veterans underscores the necessity of integrating high-quality analogue differential pressure gauges into complex systems. Feedback from long-term users highlights improved process control, reduced cost of ownership, and enhanced safety measures as key benefits. These advantages stem from the gauges' proven track record, reinforcing their status as a trustworthy component in critical operations. In conclusion, the merits of high-quality analogue differential pressure gauges are evident across multiple dimensions of experience, expertise, authority, and trustworthiness. They not only fulfill essential measurement roles but do so with a level of reliability that solidifies their indispensability in high-stakes environments. For industries where precision and durability are non-negotiable, these gauges remain a cornerstone of operational excellence.

Authoritative figures in instrumentation technology often emphasize the importance of selecting a gauge that provides consistent accuracy. A high-quality analogue differential pressure gauge is meticulously engineered to offer precise measurements, with negligible deviation over extended periods. This consistency is paramount for sectors where minute pressure changes can have profound implications on safety and product quality. Manufacturers carry out rigorous testing to ensure that each gauge meets stringent industry standards, thus bolstering their credibility and bolstering user trust. In terms of expertise, professionals in various industries acknowledge the critical role these devices play in maintaining operational efficiency. Energy companies, for instance, rely on these gauges to monitor and regulate pressure in pipelines and storage facilities, preventing leaks and ensuring compliance with safety standards. Likewise, in chemical plants, analogue differential pressure gauges monitor reaction systems to maintain optimal conditions, safeguarding both personnel and equipment from hazardous events. Experience shared by industry veterans underscores the necessity of integrating high-quality analogue differential pressure gauges into complex systems. Feedback from long-term users highlights improved process control, reduced cost of ownership, and enhanced safety measures as key benefits. These advantages stem from the gauges' proven track record, reinforcing their status as a trustworthy component in critical operations. In conclusion, the merits of high-quality analogue differential pressure gauges are evident across multiple dimensions of experience, expertise, authority, and trustworthiness. They not only fulfill essential measurement roles but do so with a level of reliability that solidifies their indispensability in high-stakes environments. For industries where precision and durability are non-negotiable, these gauges remain a cornerstone of operational excellence.

Share

Latest news

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025