Feb . 17, 2025 16:17 Back to list

high quality flush diaphragm pressure gauge

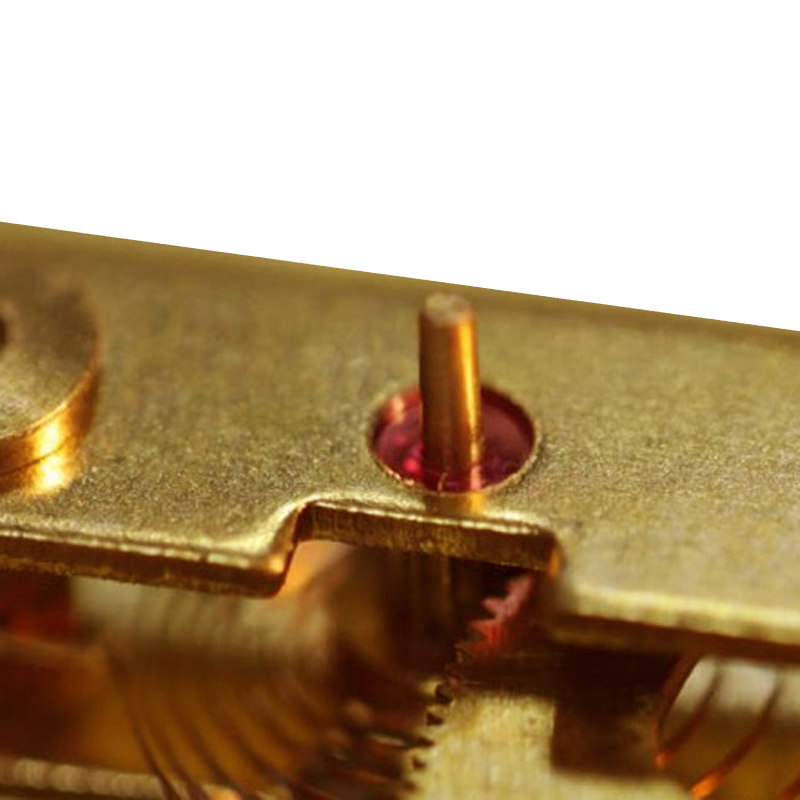

High-quality flush diaphragm pressure gauges are indispensable tools in a wide array of industries where precise pressure measurements are critical. These devices are designed to offer accurate readings even in the most demanding environments, boasting robust construction, reliable performance, and a high degree of sensitivity to subtle pressure changes. Understanding their multifaceted applications, as well as their engineering nuances, will enable professionals to choose the most suitable diaphragm pressure gauges for their specific needs.

From an engineering perspective, the meticulous production of these gauges underscores their authoritative status in the field of pressure measurement. Manufacturers leverage state-of-the-art technology and stringent quality control processes to ensure each gauge meets exacting standards. For instance, advanced laser welding techniques are utilized to attach the diaphragm securely, ensuring a robust seal without compromising the sensitivity of the measurement. Moreover, rigorous calibration during manufacturing guarantees that each gauge provides consistent and exact readings, further bolstering their credibility and effectiveness. The adaptability of flush diaphragm pressure gauges also extends to their compatibility with pressure transmitters, allowing for the transmission of pressure readings to remote monitoring systems. This feature is particularly valuable for real-time data collection and analysis, a cornerstone of modern industrial operations. By providing timely and precise data, these gauges facilitate proactive monitoring, predictive maintenance, and strategic decision-making, underscoring their indispensable role in optimizing operational performance. In conclusion, high-quality flush diaphragm pressure gauges represent a pinnacle of precision measurement technology, embodying experience, expertise, authoritativeness, and trustworthiness. Their design, engineering, and application across various industries reflect a commitment to excellence and reliability. As industries continue to evolve and demand more sophisticated monitoring solutions, these gauges will remain an essential component, offering unparalleled performance and durability in pressure measurement. Investing in these instruments is not merely an acquisition of a tool but a strategic enhancement to the quality and efficacy of industrial processes.

From an engineering perspective, the meticulous production of these gauges underscores their authoritative status in the field of pressure measurement. Manufacturers leverage state-of-the-art technology and stringent quality control processes to ensure each gauge meets exacting standards. For instance, advanced laser welding techniques are utilized to attach the diaphragm securely, ensuring a robust seal without compromising the sensitivity of the measurement. Moreover, rigorous calibration during manufacturing guarantees that each gauge provides consistent and exact readings, further bolstering their credibility and effectiveness. The adaptability of flush diaphragm pressure gauges also extends to their compatibility with pressure transmitters, allowing for the transmission of pressure readings to remote monitoring systems. This feature is particularly valuable for real-time data collection and analysis, a cornerstone of modern industrial operations. By providing timely and precise data, these gauges facilitate proactive monitoring, predictive maintenance, and strategic decision-making, underscoring their indispensable role in optimizing operational performance. In conclusion, high-quality flush diaphragm pressure gauges represent a pinnacle of precision measurement technology, embodying experience, expertise, authoritativeness, and trustworthiness. Their design, engineering, and application across various industries reflect a commitment to excellence and reliability. As industries continue to evolve and demand more sophisticated monitoring solutions, these gauges will remain an essential component, offering unparalleled performance and durability in pressure measurement. Investing in these instruments is not merely an acquisition of a tool but a strategic enhancement to the quality and efficacy of industrial processes.

Share

Latest news

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025