Feb . 16, 2025 09:01 Back to list

diaphragm capsule pressure gauge,

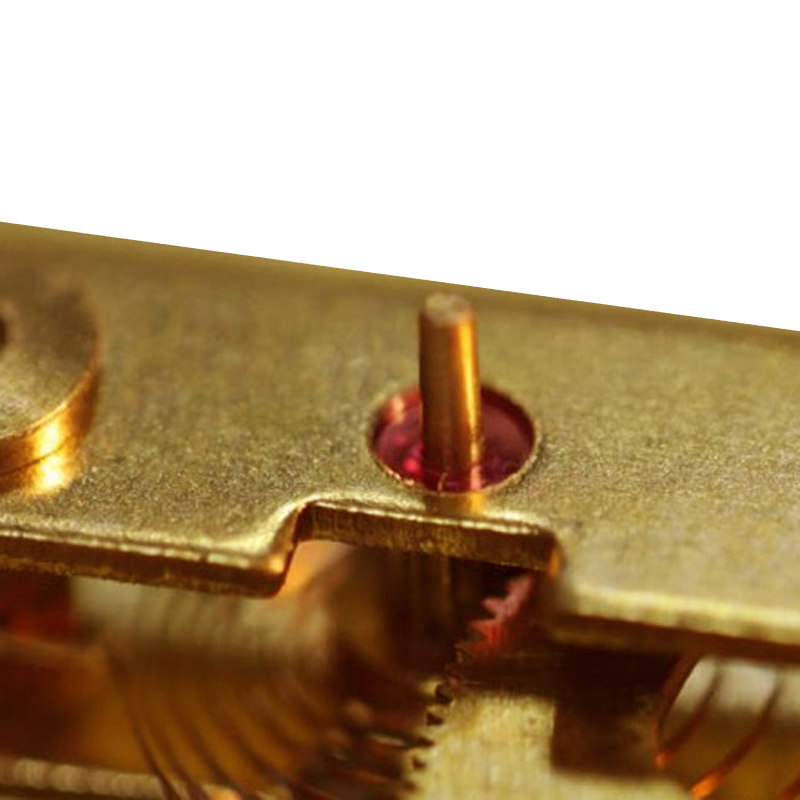

Understanding the concept of a high-quality diaphragm pressure gauge involves delving into its intricate design, functionality, and applications across different industries. Diaphragm pressure gauges are essential instruments used for measuring pressure in systems where the media may be viscous, corrosive, or prone to crystallization. By employing advanced technology and materials, these gauges offer reliability and accuracy in challenging environments, ensuring operational efficiency and safety.

Trustworthiness is another critical aspect of high-quality diaphragm pressure gauges. Users rely on these instruments to provide accurate and reliable data, a requirement that is non-negotiable in industries where safety and precision are paramount. To maintain trust, manufacturers conduct extensive testing and quality assurance procedures, which include endurance tests, pressure limit evaluations, and environmental compatibility assessments. The ability of a diaphragm pressure gauge to perform consistently over time is a testament to its trustworthiness, providing users with confidence in the readings it delivers. The applications of high-quality diaphragm pressure gauges are vast and varied. In industries like oil and gas, they are used to ensure the safe extraction, refinement, and distribution of products. In the chemical industry, they are crucial for maintaining precise control over complex chemical reactions. Similarly, in the food and beverage industry, these gauges help maintain hygienic standards by preventing contamination from gauge media. The adaptability of diaphragm pressure gauges to different media types and environmental conditions makes them indispensable tools across a wide range of sectors. Innovation continues to drive the development of diaphragm pressure gauges, with new technologies enhancing their performance and usability. Digital displays, wireless connectivity, and advanced material sciences are being integrated to improve their accuracy, ease of use, and durability. This continuous evolution reflects the ongoing commitment to meeting the increasingly complex needs of modern industries, ensuring that diaphragm pressure gauges remain at the forefront of pressure measurement technology. In conclusion, a high-quality diaphragm pressure gauge epitomizes precision engineering, industry expertise, authoritative reliability, and enduring trustworthiness. Its ability to deliver accurate and reliable pressure measurements in challenging conditions makes it an indispensable tool in numerous critical applications. As industries continue to evolve, the role of diaphragm pressure gauges in ensuring safety, efficiency, and precision will only grow, solidifying their place as essential components in the world of pressure measurement.

Trustworthiness is another critical aspect of high-quality diaphragm pressure gauges. Users rely on these instruments to provide accurate and reliable data, a requirement that is non-negotiable in industries where safety and precision are paramount. To maintain trust, manufacturers conduct extensive testing and quality assurance procedures, which include endurance tests, pressure limit evaluations, and environmental compatibility assessments. The ability of a diaphragm pressure gauge to perform consistently over time is a testament to its trustworthiness, providing users with confidence in the readings it delivers. The applications of high-quality diaphragm pressure gauges are vast and varied. In industries like oil and gas, they are used to ensure the safe extraction, refinement, and distribution of products. In the chemical industry, they are crucial for maintaining precise control over complex chemical reactions. Similarly, in the food and beverage industry, these gauges help maintain hygienic standards by preventing contamination from gauge media. The adaptability of diaphragm pressure gauges to different media types and environmental conditions makes them indispensable tools across a wide range of sectors. Innovation continues to drive the development of diaphragm pressure gauges, with new technologies enhancing their performance and usability. Digital displays, wireless connectivity, and advanced material sciences are being integrated to improve their accuracy, ease of use, and durability. This continuous evolution reflects the ongoing commitment to meeting the increasingly complex needs of modern industries, ensuring that diaphragm pressure gauges remain at the forefront of pressure measurement technology. In conclusion, a high-quality diaphragm pressure gauge epitomizes precision engineering, industry expertise, authoritative reliability, and enduring trustworthiness. Its ability to deliver accurate and reliable pressure measurements in challenging conditions makes it an indispensable tool in numerous critical applications. As industries continue to evolve, the role of diaphragm pressure gauges in ensuring safety, efficiency, and precision will only grow, solidifying their place as essential components in the world of pressure measurement.

Share

Latest news

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025