Dec . 13, 2024 13:50 Back to list

high quality precision instrument pressure gauges

High-Quality Precision Instrument Pressure Gauges Ensuring Accuracy and Reliability in Measurement

In various industries, accurate measurement of pressure is critical for maintaining safety, efficiency, and quality control. High-quality precision instrument pressure gauges play a vital role in achieving these goals. As the backbone of many industrial processes, these instruments are designed to provide reliable and accurate pressure readings, which are essential for system performance monitoring, troubleshooting, and compliance with safety regulations.

Understanding Pressure Gauges

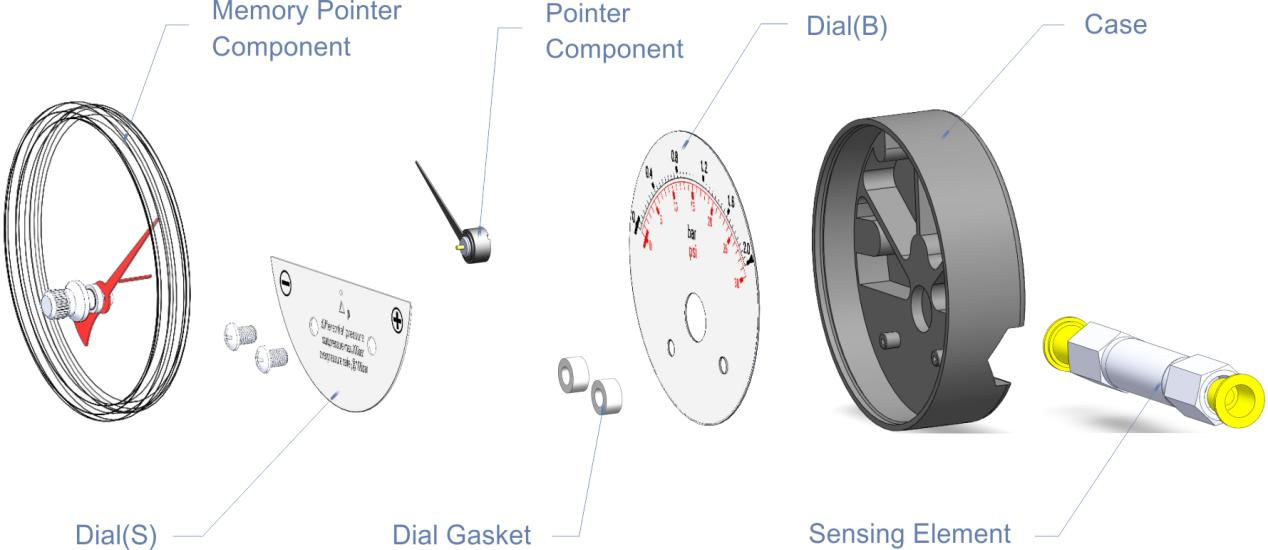

A pressure gauge is an instrument used to measure the pressure of gases or liquids within a system. Typically, these gauges consist of a sensing element, which responds to pressure changes, and a dial or digital display that indicates the pressure level. Pressure gauges can be categorized into several types, including mechanical, electronic, and digital gauges. Each type has its unique advantages and is suited for specific applications, ranging from hydraulic systems to pneumatic equipment.

The Importance of Precision

Precision in pressure measurement cannot be overstated. Inaccurate readings can lead to catastrophic failures, excessive wear on equipment, suboptimal operation conditions, and even safety hazards. High-quality precision pressure gauges are designed to minimize errors, ensuring that operators receive accurate and consistent measurements. Factors contributing to precision include the gauge's construction materials, design, calibration processes, and manufacturing standards.

High-quality pressure gauges typically feature a Bourdon tube, diaphragm, or piezoresistive sensor as their sensing element. These components are engineered to provide high sensitivity and responsiveness to pressure fluctuations, ensuring that even the smallest changes in pressure are detected. Moreover, advanced calibration techniques and stringent quality controls during manufacturing further enhance the accuracy of these instruments.

Durability and Performance

high quality precision instrument pressure gauges

Beyond accuracy, durability and performance are key considerations when selecting pressure gauges. Operating in harsh environments—such as high temperatures, corrosive atmospheres, or exposed to physical shocks—can compromise the functionality of inferior gauges. Therefore, high-quality pressure gauges are constructed from resistant materials like stainless steel, brass, or specialized plastics.

In many industrial applications, gauges must not only withstand extreme conditions but also maintain performance over time. A reliable pressure gauge should offer stability and longevity, reducing the need for frequent replacements and maintenance. This reliability ultimately contributes to operational efficiency and cost savings.

Applications Across Industries

High-quality precision instrument pressure gauges find applications across a wide range of industries. In oil and gas, they are used to monitor pipeline pressures, ensuring safe transport and extraction processes. In manufacturing, gauges help regulate pressure in hydraulic systems, optimizing performance and reducing energy consumption. Similarly, in the medical field, pressure gauges are crucial in devices like anesthesia machines and ventilators, where accurate pressure measurements are essential for patient safety.

The growing trend of automation and digitalization in manufacturing also drives the demand for advanced pressure monitoring solutions. Smart pressure gauges equipped with digital interfaces and connectivity options facilitate real-time monitoring and data logging, enabling operators to make informed decisions swiftly.

Choosing the Right Gauge

When selecting a pressure gauge, it’s essential to consider several factors, including the range of pressure to be measured, the type of pressure (gauge, absolute, or differential), and the specific environmental conditions. Additionally, the maintenance requirements and service life of the gauge should also be evaluated.

In conclusion, high-quality precision instrument pressure gauges are indispensable tools in modern industry. They ensure that pressure measurements are accurate, reliable, and suitable for various applications, from heavy industrial processes to delicate medical equipment. Investing in superior pressure gauges not only enhances operational safety and efficiency but also underscores a commitment to quality that resonates throughout an organization. As industries evolve, the importance of precision in pressure measurement will continue to grow, making the choice of the right pressure gauge more critical than ever.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025