Sep . 28, 2024 16:00 Back to list

Understanding the Functionality of Isolating Diaphragm Pressure Gauges in Industry Applications

Isolating Diaphragm Pressure Gauges Understanding Their Importance and Functionality

Pressure measurement is a critical part of numerous industrial processes, providing essential data for efficient and safe operations. One of the key tools in achieving precise pressure measurements is the isolating diaphragm pressure gauge. This specialized device offers unique advantages, particularly in applications where corrosive or viscous fluids are present.

At its core, an isolating diaphragm pressure gauge consists of a diaphragm that separates the measuring element from the process fluid. This diaphragm is typically made from materials that can withstand challenging conditions, such as corrosion, high temperature, or mechanical stress. By using this design, the gauge can accurately measure pressure without being directly exposed to the fluid, thereby prolonging its lifespan and ensuring reliable performance.

The primary purpose of an isolating diaphragm pressure gauge is to protect the sensing element, often a Bourdon tube or a piezoresistive sensor, from damaging effects caused by the process fluid. Many industrial applications involve aggressive chemicals, slurries, or sticky materials that can clog or corrode traditional pressure gauges. By employing an isolating diaphragm, these gauges remain functional, providing accurate readings even in the most challenging environments.

One of the significant advantages of isolating diaphragm pressure gauges is their versatility. They can be used in a wide range of industries, including oil and gas, chemical processing, food and beverage, pharmaceuticals, and wastewater management. In each of these sectors, the need for robust and reliable pressure measurement is paramount, necessitating the use of advanced technologies like isolating diaphragms.

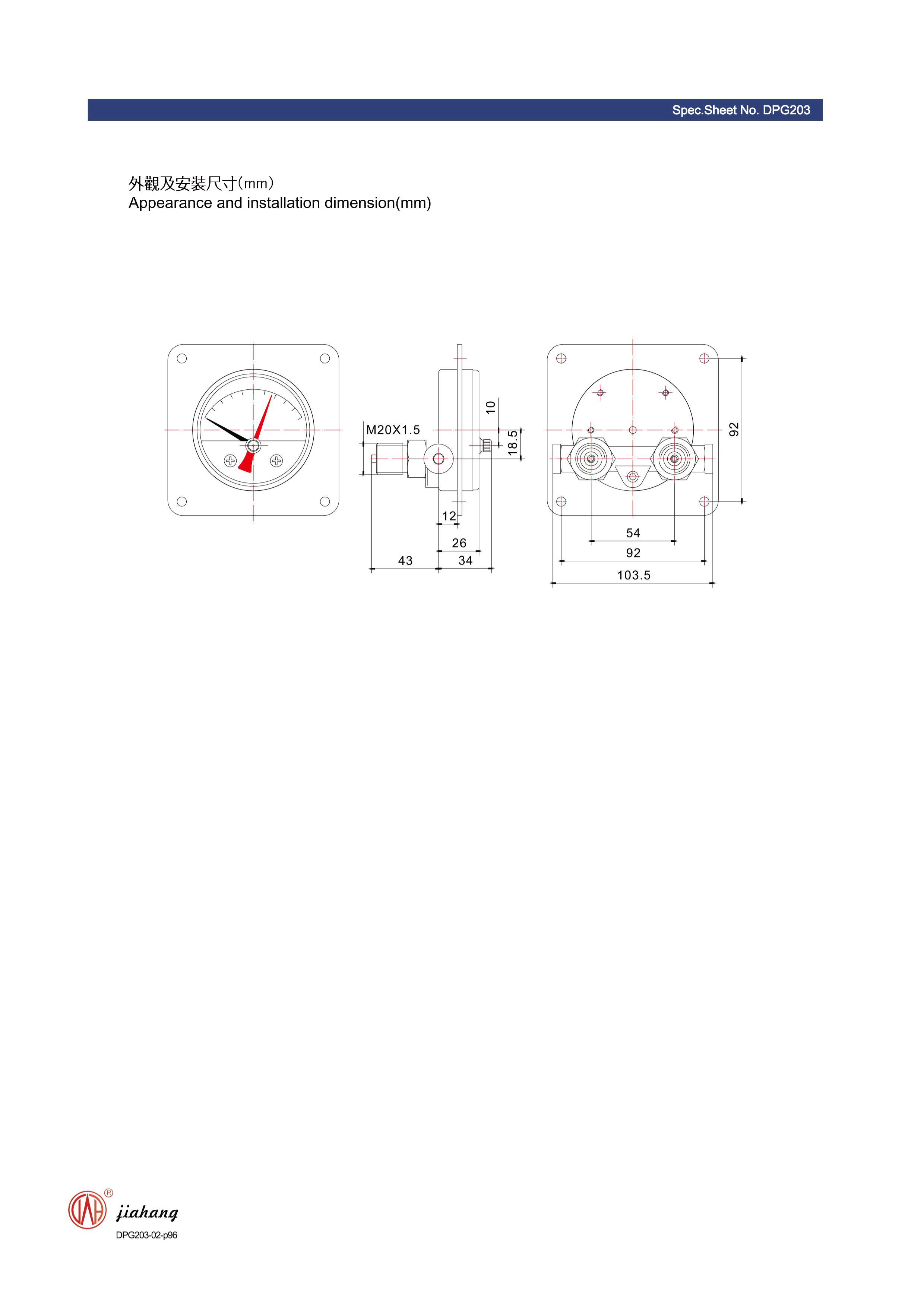

isolating diaphragm pressure gauge

In addition to their protective capabilities, isolating diaphragm pressure gauges can also improve the accuracy of pressure readings. The diaphragm allows for a more uniform pressure transfer to the sensing element, helping to eliminate errors that might occur due to turbulence or other factors associated with direct contact. This enhanced accuracy is crucial in applications where precise measurements are required for regulatory compliance or safety.

Another important feature of isolating diaphragm pressure gauges is their ability to handle varying pressure ranges and process conditions. They can be configured to measure low and high pressures, and in some cases, can be adapted to monitor differential pressures as well. This adaptability makes them an invaluable tool for engineers and operators who need to maintain tight control over process parameters.

Furthermore, the installation of isolating diaphragm pressure gauges is typically straightforward. They can be fitted into existing systems with minimal modifications, making it easy to upgrade from standard gauges to more specialized options without significant downtime. This is particularly beneficial in industries where operational continuity is paramount.

Despite their many advantages, it is essential to select the right isolating diaphragm gauge for specific applications. Factors such as the type of process fluid, temperature, pressure range, and the desired accuracy must all be considered during the selection process. Additionally, regular maintenance and calibration are necessary to ensure long-term reliability and performance.

In conclusion, isolating diaphragm pressure gauges play a crucial role in modern industrial applications by providing accurate and reliable pressure measurements in challenging environments. Their ability to protect sensitive measuring elements, improve accuracy, and adapt to various conditions makes them indispensable in many sectors. As industries continue to evolve and face new challenges, the importance of such advanced measurement technologies will undoubtedly grow, ensuring safe and efficient operations.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025