Sep . 25, 2024 20:42 Back to list

jah diaphragm and capsule pressure gauges

Understanding Jah Diaphragm and Capsule Pressure Gauges

In various industrial and laboratory settings, the accurate measurement of pressure is crucial for operational efficiency and safety. Among the many types of pressure gauges available, Jah diaphragm and capsule pressure gauges stand out for their reliability and precision. These instruments are widely utilized for both gaseous and liquid applications, making them essential tools in monitoring and controlling pressure in diverse environments.

Jah Diaphragm Pressure Gauges

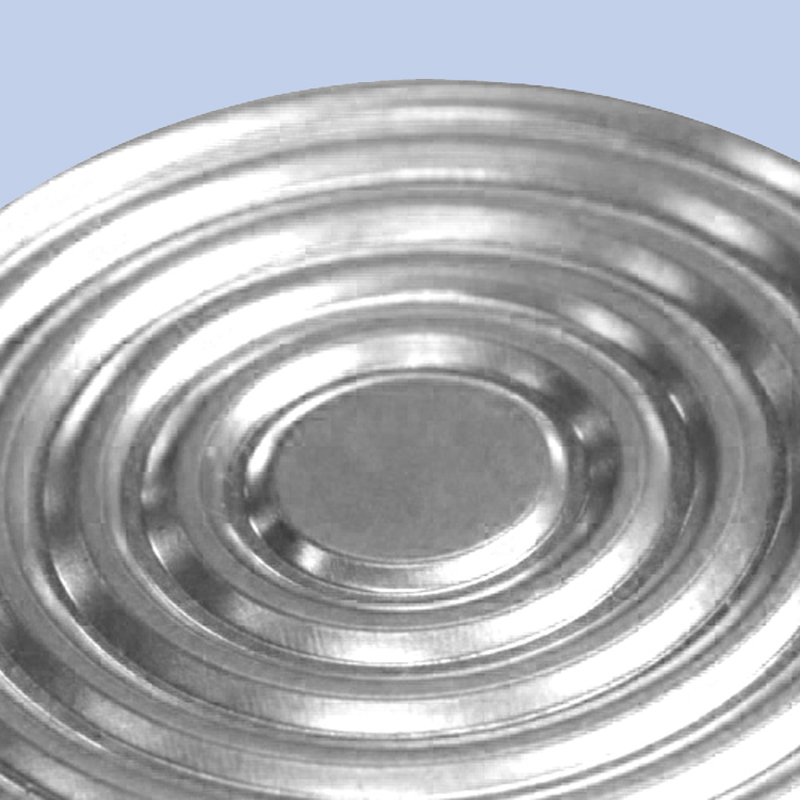

Diaphragm pressure gauges operate based on the principle of a flexible diaphragm that deflects under pressure. When the pressure in the system increases, it causes the diaphragm to bend, which is then translated into a readable pressure measurement via mechanical linkages connected to a dial. Jah diaphragm gauges are particularly known for their robust construction, providing resistance to corrosion and mechanical shocks, making them ideal for demanding applications.

These gauges are available in various materials such as stainless steel or brass, allowing them to handle different media, including corrosive substances. The design of the diaphragm also plays a significant role in their performance; it ensures that the gauge can handle dynamic pressures without significant hysteresis—a critical aspect for systems where pressure fluctuations are common.

Capsule Pressure Gauges

On the other hand, capsule pressure gauges utilize a different mechanism involving two metallic capsules that expand or contract based on the pressure exerted by the measured fluid. The capsules are usually connected through a shaft to a pointer that moves across a calibrated dial. This type of gauge is particularly suited for low-pressure applications, typically below 30 psi (pounds per square inch), making them ideal for sensitive measurements like those found in laboratory settings.

jah diaphragm and capsule pressure gauges

Jah capsule pressure gauges are favored for their high accuracy and sensitivity. They can reliably measure small pressure changes, which is vital in processes where precise pressure control is necessary. Furthermore, the compact design of capsule gauges makes them easy to install and integrate into existing systems without requiring significant modifications.

Applications and Benefits

Both Jah diaphragm and capsule pressure gauges serve a multitude of applications across industries such as petrochemical, pharmaceuticals, food and beverage, and even HVAC systems. Their ability to deliver accurate pressure readings helps in ensuring compliance with safety standards, enhancing process efficiency, and prolonging the lifespan of equipment.

Some notable benefits of using Jah pressure gauges include their reliability in harsh environments, low maintenance requirements, and suitability for a wide range of fluids and gases. The versatility of these gauges allows engineers and technicians to select the most appropriate type based on specific pressure ranges and application needs.

Conclusion

In conclusion, Jah diaphragm and capsule pressure gauges represent an essential component of pressure measurement technology. Their design and operational efficiency make them suitable for various industrial applications, providing accurate readings that are crucial for safety and performance. Understanding the distinctions between these two types of gauges allows operators to make informed decisions that enhance operational reliability and efficiency in their respective fields. Whether dealing with delicate laboratory experiments or rugged industrial processes, Jah pressure gauges offer dependable solutions for pressure measurement needs.

-

HD Fire Pressure Gauges High Accuracy & Durable Solutions

NewsMay.28,2025

-

Custom Singles Capsule Systems Top Exporters & Factories

NewsMay.28,2025

-

Piston-Style Differential Pressure Gauges Precision & Durability

NewsMay.28,2025

-

WIKA Differential Pressure Gauge 700.04 High-Accuracy Industrial Measurement

NewsMay.28,2025

-

Precision Differential Pressure Gauge Factory Custom Solutions & OEM Services

NewsMay.27,2025

-

Pressure Diaphragm Capsule Elements High-Accuracy & Durable Solutions

NewsMay.27,2025