Dec . 13, 2024 04:28 Back to list

Differential Pressure Gauges in Pharmaceutical Applications for Enhanced Process Control and Safety

Understanding Differential Pressure Gauges in the Pharmaceutical Industry

In the pharmaceutical industry, maintaining precise control over manufacturing environments is paramount. One of the critical instruments in achieving this precision is the differential pressure gauge. These devices are essential for monitoring the pressure differences between two points, enabling manufacturers to ensure that processes conform to stringent regulatory standards and quality requirements.

What is a Differential Pressure Gauge?

A differential pressure gauge is an instrument that measures the difference in pressure between two points in a system. It can provide crucial insights into the status of various processes, including filtration, cleanroom monitoring, and fluid flow in pipeline systems. The gauge can be either mechanical or electronic, with electronic versions offering advanced features such as digital displays, data logging, and connectivity to process control systems.

Importance in the Pharmaceutical Industry

1. Maintaining Cleanroom Environments In pharmaceutical manufacturing, cleanrooms are required for the production of sterile products. Differential pressure gauges help monitor the air pressure difference between the cleanroom and adjacent areas. Maintaining a positive pressure in the cleanroom compared to outside areas prevents contamination, thereby ensuring the integrity of the pharmaceutical products.

2. Filtration Processes Differential pressure gauges are vital in monitoring the performance of filters used in various applications, such as air filtration and liquid filtration. By measuring the pressure drop across a filter, manufacturers can determine its efficiency and detect when it needs to be replaced. A significant increase in pressure difference indicates that the filter is clogged, which can affect product quality and safety.

3. Safety Monitoring In pharmaceutical processes, certain operations, such as those involving volatile chemicals or gases, require strict monitoring of pressure conditions to ensure safety. Differential pressure gauges alert operators to any discrepancies that could lead to system failures or hazardous conditions, providing a critical layer of safety in facilities where pharmaceutical products are produced.

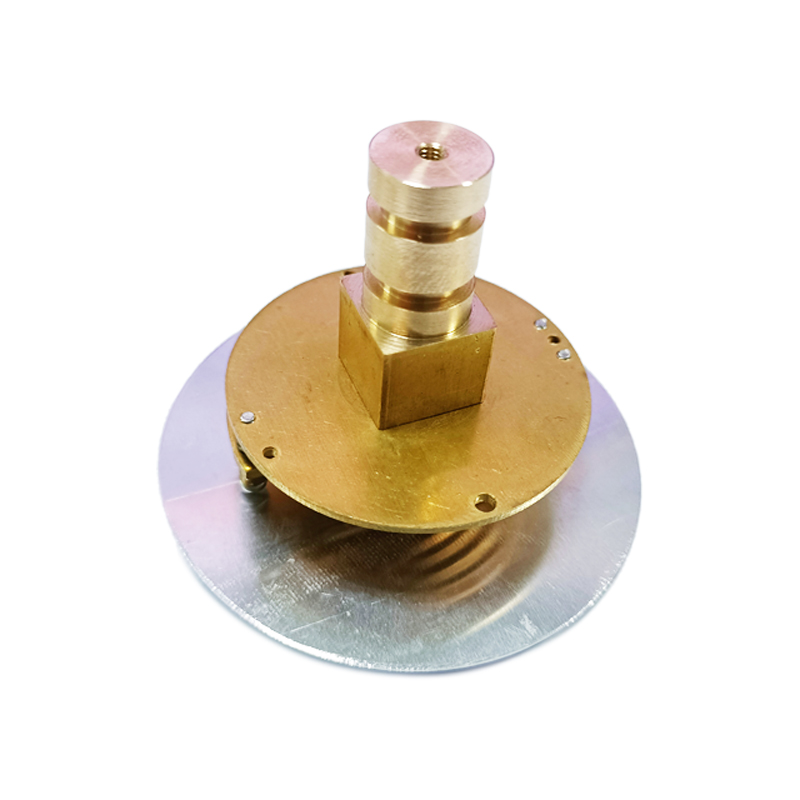

jah differential pressure gauge in pharma industry

Selection Criteria for Differential Pressure Gauges

When selecting a differential pressure gauge for pharmaceutical applications, several key factors must be considered

- Accuracy The accuracy of the gauge is vital for reliable measurements. In pharmaceuticals, even small deviations can lead to significant implications for product quality and compliance.

- Material Compatibility The materials used in the construction of the gauge must be compatible with the chemicals and substances they will encounter in the environment. This helps to prevent contamination and ensures the longevity of the equipment.

- Certification and Compliance Given the rigorous standards enforced in the pharmaceutical industry (such as FDA regulations), it is essential that differential pressure gauges are compliant with relevant regulations and certified by recognized standards organizations.

- Installation and Maintenance The ease of installation and maintenance should also be considered. Devices that require minimal intervention and provide clear maintenance indicators can save time and reduce operational costs.

Conclusion

Differential pressure gauges serve as a critical component of monitoring and ensuring the quality and safety of pharmaceutical products. Their role in maintaining cleanroom environments, monitoring filtration systems, and ensuring safe operational conditions cannot be overstated. By understanding the key functions and selection criteria of these gauges, pharmaceutical manufacturers can enhance their process reliability and product quality, ultimately leading to better outcomes for patients relying on pharmaceutical advancements. As the industry continues to evolve and face new challenges, the importance of precise measurement tools like differential pressure gauges will remain paramount in safeguarding public health and trust in pharmaceutical products.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025