Oct . 02, 2024 20:39 Back to list

Five Valve Manifold System for Jah Differential Pressure Gauges in Process Control

Understanding the JAH Differential Pressure Gauge with 5-Valve Manifold

In industrial applications, precise measurement of pressure difference is crucial for monitoring and controlling processes. One such tool widely used for this purpose is the JAH Differential Pressure Gauge, which is often paired with a 5-valve manifold. This combination offers a reliable and efficient solution for day-to-day operational requirements.

What is a Differential Pressure Gauge?

A differential pressure gauge is designed to measure the pressure difference between two points in a system. This measurement is vital in various industries, such as oil and gas, water treatment, and HVAC, where it can indicate flow rates, filter status, or level measurements in tanks. The JAH differential pressure gauge excels in providing accurate readings under different conditions, enabling operators to make informed decisions based on real-time data.

The Role of the 5-Valve Manifold

The integration of a 5-valve manifold with a differential pressure gauge enhances its functionality significantly. The manifold consists of five valves which facilitate various operations such as isolation, venting, and calibration. Here’s a breakdown of the five valves

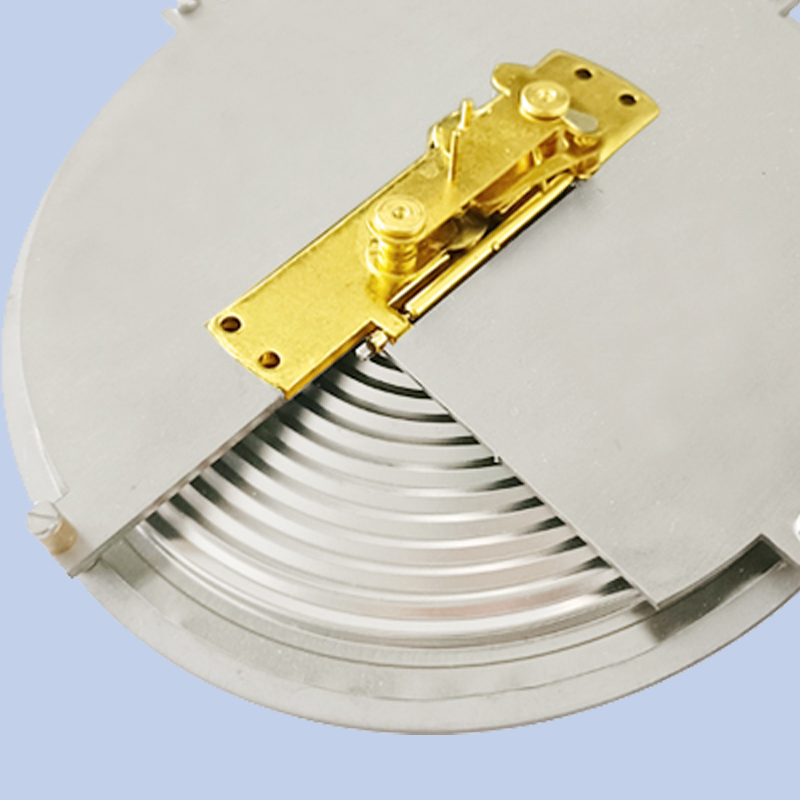

jah differential pressure gauge with 5 valve manifold

1. High-pressure Isolation Valve This valve isolates the high-pressure side of the differential pressure system, allowing safe maintenance and calibration without disrupting the entire system. 2. Low-pressure Isolation Valve Similar to the high-pressure valve, this one isolates the low-pressure side, ensuring that adjustments can be made without affecting system performance. 3. Venting Valve This valve allows for the safe venting of pressure from the system, which is critical in preventing damage during maintenance or calibration. 4. Calibration Valve This valve is used to calibrate the differential pressure gauge, ensuring that it provides accurate readings. 5. Draining Valve This final valve facilitates the drainage of fluid from the system, helping to maintain optimal functionality and accuracy.

Benefits of Using JAH Differential Pressure Gauge with a 5-Valve Manifold

The JAH differential pressure gauge paired with a 5-valve manifold offers several advantages

- Enhanced Accuracy The manifold allows for precise isolation and calibration, resulting in more accurate pressure readings. - Ease of Maintenance With isolation valves, maintenance can be performed safely and efficiently without shutting down entire systems. - Versatile Applications This setup can be used in various industries, making it a versatile choice for many applications. - Cost Efficiency By minimizing downtime and maintaining optimal performance, this combination can lead to significant cost savings in an industrial setting.

Conclusion

In conclusion, the JAH differential pressure gauge combined with a 5-valve manifold represents a robust solution for measuring pressure differences in various industrial applications. Its design allows for enhanced accuracy, ease of maintenance, and versatility, making it an essential tool for operators looking to ensure efficient and safe system operations. Investing in such technology not only guarantees seamless process control but also supports the overall efficiency and safety of industrial operations. For businesses aiming to optimize their processes, the JAH differential pressure gauge with a 5-valve manifold is undoubtedly worth considering.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025