Nov . 16, 2024 05:27 Back to list

jah high temp differential pressure gauge

Understanding the High-Temperature Differential Pressure Gauge

In various industrial applications, monitoring pressure changes is essential for maintaining system integrity and performance. One critical instrument used in such monitoring is the High-Temperature Differential Pressure Gauge (HTDPG). This device plays a pivotal role in measuring the difference in pressure between two points in a system where the temperature may significantly influence the readings. This article delves into the key aspects, working principles, applications, and advantages of high-temperature differential pressure gauges.

What is a High-Temperature Differential Pressure Gauge?

A high-temperature differential pressure gauge is designed specifically to measure pressure differentials in environments where temperatures can reach elevated levels. These gauges are suitable for processes such as steam generation, chemical reactions, and oil processing, where both temperature and pressure are critical factors affecting system operation.

Working Principles

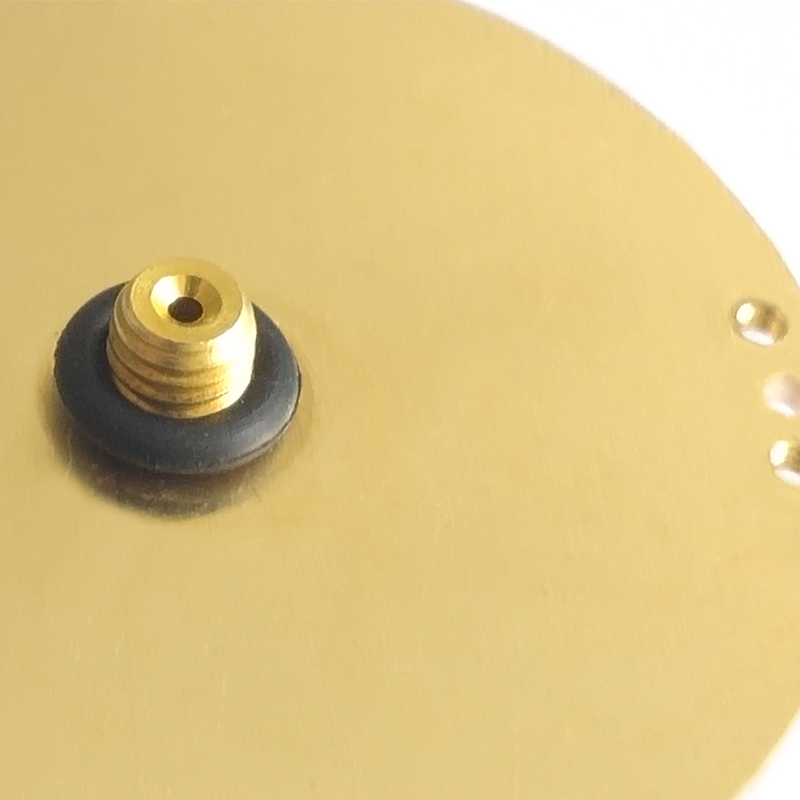

The principle behind a differential pressure gauge revolves around the measurement of pressure differences between two points. This is typically achieved using two pressure sensing ports one connected to a higher pressure zone and the other to a lower pressure zone. The gauges usually incorporate a diaphragm or membrane that responds to the pressure difference, moving in relation to the change in pressure.

Modern HTDPGs often utilize advanced materials and designs, such as stainless steel or high-temperature plastics, which can withstand harsh conditions while providing accurate readings. Some gauges may also include electronic components that allow for digital displays, providing better visualization and additional functionalities like data logging and remote monitoring.

Applications of High-Temperature Differential Pressure Gauges

1. Steam Systems In power plants and manufacturing facilities, HTDPGs are used to monitor steam pressure differentials, ensuring optimal performance of boilers and preventing operational failures.

2. Chemical Processing In reactors and separators, measuring pressure differentials helps in controlling chemical reactions and ensuring the safety of operations. The gauges assist in maintaining the required conditions by detecting variations in pressure that could indicate blockages or process inefficiencies.

jah high temp differential pressure gauge

4. HVAC Systems In heating, ventilation, and air conditioning (HVAC) systems, these gauges help maintain balanced airflow by monitoring the pressure differences across filters and coils.

5. Food Processing High-temperature processes in food manufacturing require precise pressure control to ensure product quality and safety. HTDPGs are used to monitor processes under high-temperature conditions.

Advantages of High-Temperature Differential Pressure Gauges

1. Durability HTDPGs are constructed to withstand high temperatures and harsh environments, ensuring long-term reliability in demanding applications.

2. Accuracy The design of these gauges allows for precise measurements of pressure differentials, which is crucial for the optimal functioning of various systems.

3. Safety By providing real-time monitoring of pressure differences, HTDPGs enhance safety by helping to identify potential issues before they escalate into serious problems.

4. Versatility These gauges can be used in a wide range of applications, making them a versatile choice for industries requiring high-temperature monitoring solutions.

5. Ease of Integration Many high-temperature differential pressure gauges are designed for easy integration into existing systems, minimizing installation time and effort.

Conclusion

In conclusion, high-temperature differential pressure gauges are indispensable tools in numerous industrial applications where pressure and temperature monitoring are critical. Their ability to provide accurate and reliable pressure differential measurements in extreme conditions enhances productivity, safety, and efficiency across various sectors. Understanding the importance of these gauges and their applications can lead to better system management and optimization, ultimately supporting the goals of modern industry. Whether in energy production, chemical processing, or HVAC systems, HTDPGs are fundamental components that contribute significantly to operational success.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025