Dec . 19, 2024 05:32 Back to list

jah wika 4 differential pressure gauge

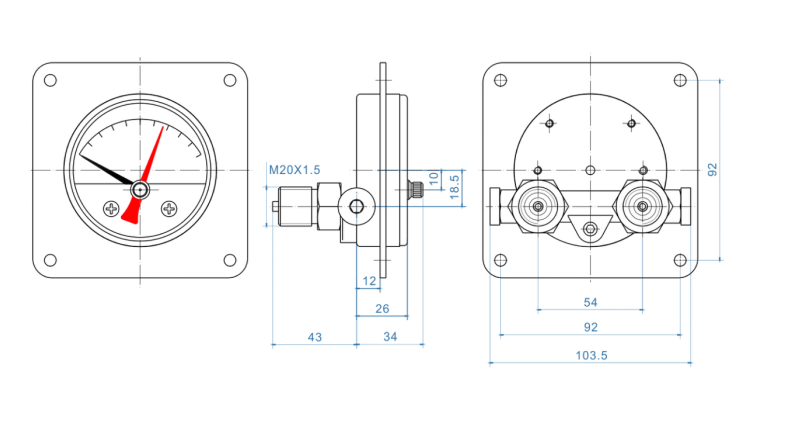

Understanding the Jah Wika 4 Differential Pressure Gauge A Comprehensive Guide

Differential pressure gauges play a crucial role in various industrial applications, providing insights into the pressure differences between two points in a system. Among the various manufacturers, Jah Wika has established a strong reputation for producing reliable and precise instruments. The Jah Wika 4 differential pressure gauge stands out due to its technology, accuracy, and ease of use. In this article, we will explore the key features, applications, and benefits of the Jah Wika 4 differential pressure gauge.

What is a Differential Pressure Gauge?

A differential pressure gauge measures the difference in pressure between two points. This difference can indicate flow rate, filter clogging, or liquid levels, making it an essential tool in many industries such as oil and gas, pharmaceuticals, and water treatment. The Jah Wika 4 differential pressure gauge offers an efficient way to monitor these variances, ensuring smooth operations and preventing potential issues before they escalate.

Key Features of the Jah Wika 4 Differential Pressure Gauge

1. High Precision and Accuracy One of the standout features of the Jah Wika 4 is its high level of accuracy. Equipped with advanced measuring technology, it can deliver precise readings even under fluctuating conditions. This reliability is critical in applications where small pressure variances can have significant implications.

2. Robust Design The gauge is constructed from high-quality materials designed to withstand harsh industrial environments. This rugged build ensures longevity and maintenance-free operation, which translates into cost savings for businesses.

3. Wide Range of Applications The Jah Wika 4 is versatile and can be used in various applications, including HVAC systems, hydraulic systems, and filtration. Its ability to measure both liquid and gas pressures makes it an invaluable asset across different sectors.

4. User-Friendly Interface The gauge features an intuitive design that allows operators to read measurements with ease. Its clear display ensures quick interpretation of data, facilitating timely decision-making.

5. Safety Features Given the nature of pressure measurements, safety is paramount. The Jah Wika 4 is designed with safety features that prevent overpressure situations, ensuring that operators are protected while obtaining necessary data.

jah wika 4 differential pressure gauge

Applications of Jah Wika 4 Differential Pressure Gauge

Differential pressure gauges, particularly the Jah Wika 4, find applications in numerous fields. Here are some examples

- HVAC Systems In heating, ventilation, and air conditioning systems, differential pressure gauges help monitor filter conditions and fan performance, ensuring optimal system efficiency. - Water Treatment These gauges are used in water treatment facilities to monitor pressure drops across filtration systems, helping to determine when filters need maintenance or replacement. - Oil and Gas In the oil and gas industry, differential pressure gauges are essential for monitoring flow rates and ensuring the safety of operations. They can provide vital information during extraction and processing stages.

- Pharmaceuticals The pharmaceutical industry relies on stringent quality controls, and differential pressure gauges help maintain conditions for various processes, including sterile applications.

Benefits of Using the Jah Wika 4 Differential Pressure Gauge

- Enhanced Operational Efficiency By providing real-time pressure data, the Jah Wika 4 enables operators to optimize processes, reduce downtime, and improve overall operational efficiency. - Cost-Effective Maintenance With its robust design and accurate measurements, the Jah Wika 4 reduces the likelihood of unexpected failures, leading to lower maintenance costs over time.

- Improved Safety Standards The built-in safety features help prevent accidents caused by overpressure situations, contributing to a safer working environment.

- Data-Driven Decisions The accurate readings provided by the gauge enable informed decision-making, ensuring that operations run smoothly and that any necessary adjustments are made proactively.

Conclusion

The Jah Wika 4 differential pressure gauge represents a perfect blend of reliability, accuracy, and user-friendliness. Its robust design and wide range of applications make it an ideal choice for various industries. By investing in this gauge, businesses can improve their operational efficiency, ensure safety, and reduce maintenance costs, ultimately leading to a more efficient and productive workflow. Whether in HVAC systems, water treatment facilities, or oil and gas operations, the Jah Wika 4 is an essential tool for those who value precision and functionality in their monitoring equipment.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025