Oct . 12, 2024 12:31 Back to list

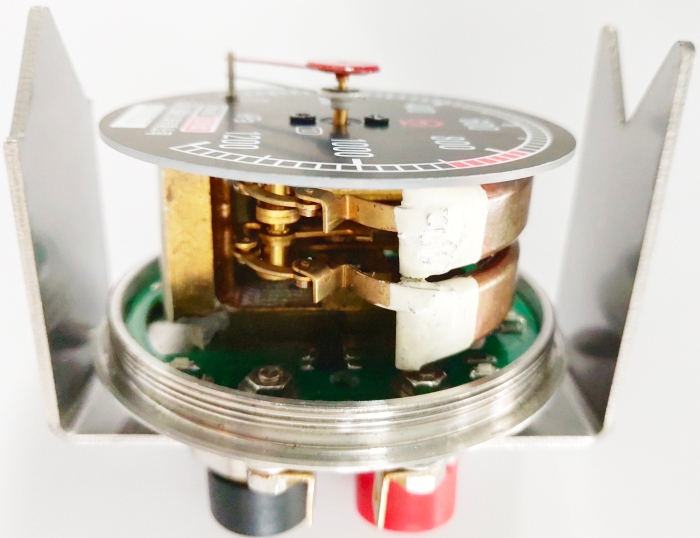

low range differential pressure gauge product

Understanding Low Range Differential Pressure Gauges

In various industrial applications, precise measurement of pressure differences is crucial for maintaining the safety, efficiency, and functionality of systems. One essential tool used in this context is the low range differential pressure gauge. This specialized instrument allows operators to monitor small pressure differentials, which can be vital in processes where even slight variations can have significant impacts.

What is a Differential Pressure Gauge?

A differential pressure gauge measures the difference in pressure between two points. Unlike standard pressure gauges that measure only absolute or gauge pressure, differential pressure gauges can provide insights into how systems are performing by monitoring the pressure drop across various components, such as filters, valves, or any other devices that resist flow.

Applications of Low Range Differential Pressure Gauges

Low range differential pressure gauges are specifically designed for applications where pressure differences are minimal, typically in the range of a few inches of water column (inWC) up to a few psi. These gauges are commonly used in

1. Filtration Systems In processes such as air and water filtration, monitoring the differential pressure across a filter can indicate when it needs to be cleaned or replaced. A significant increase in pressure drop often signifies that the filter is becoming clogged.

2. HVAC Systems In heating, ventilation, and air conditioning systems, maintaining balanced airflow is essential for efficiency and comfort. Low range differential pressure gauges can help monitor air pressure differences across duct systems to ensure proper operation.

3. Laboratories In controlled environments, low differential pressure measurements can help maintain sterile conditions or confirm the effectiveness of containment systems in laboratories.

low range differential pressure gauge product

4. Medical Equipment In medical applications, differential pressure gauges can be vital for monitoring systems such as ventilators, where maintaining adequate airflow is crucial for patient safety.

Key Features of Low Range Differential Pressure Gauges

When selecting a low range differential pressure gauge, several features should be considered

- Accuracy High accuracy is crucial for applications requiring precise measurements. The best gauges will often feature a calibration certification to ensure reliability.

- Scale Range Depending on the application, it is important to choose a gauge that covers the required pressure range without compromising precision.

- Material Compatibility Gauges should be constructed from materials suitable for the media being measured, avoiding corrosion or leakage issues.

- Mounting Options Depending on installation constraints, gauges come with various mounting options (panel, surface, or remote).

Conclusion

Low range differential pressure gauges play a critical role in ensuring the optimal operation of various systems across different industries. They deliver valuable insights that facilitate timely maintenance, optimize performance, and enhance safety. As industries continue to evolve and prioritize efficiency, having the right measuring instruments, such as low range differential pressure gauges, will remain vital. By understanding their functions and applications, operators can make informed decisions to improve their processes and maintain the highest standards of performance and safety. As technology advances, we can expect even greater innovations in the design and functionality of these essential tools, further enhancing their role in industry and engineering applications.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025