Jun . 13, 2024 11:13 Back to list

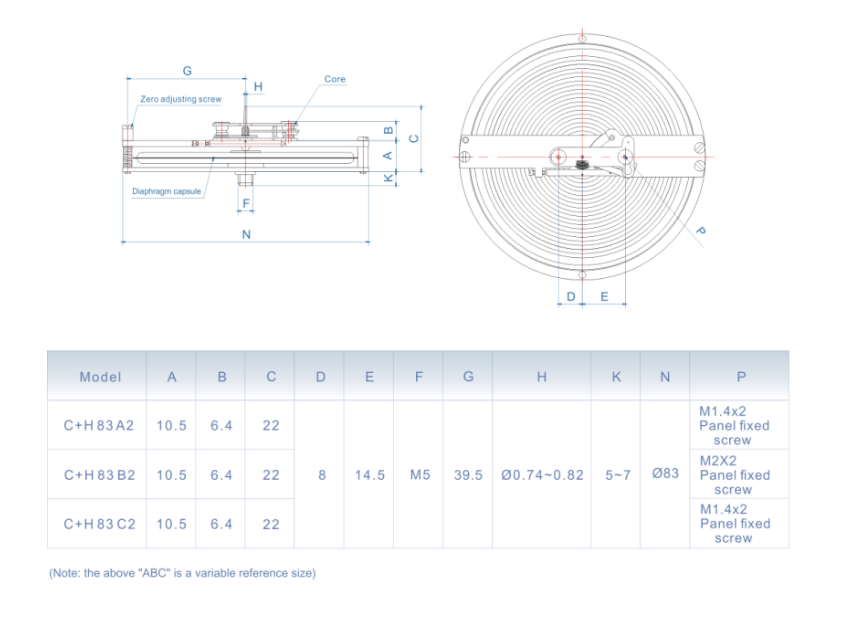

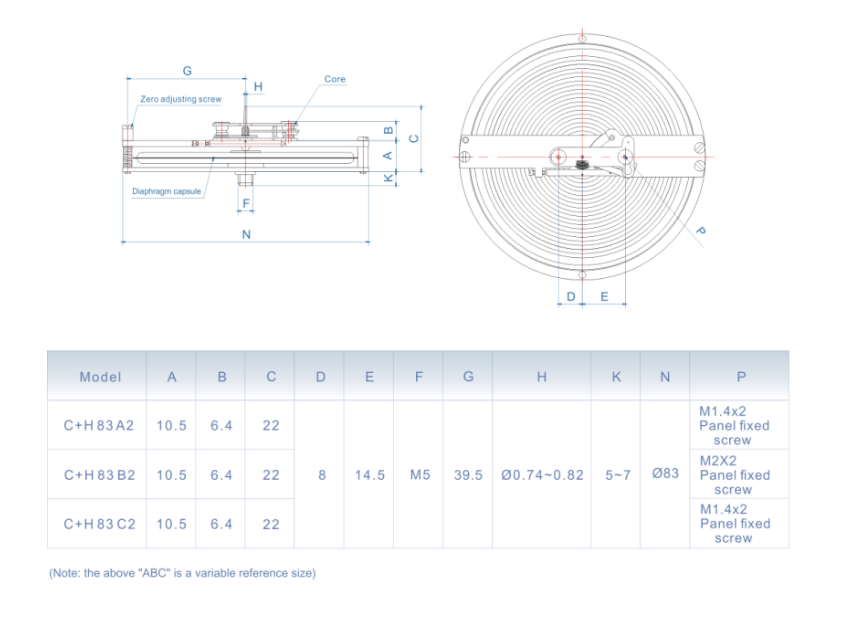

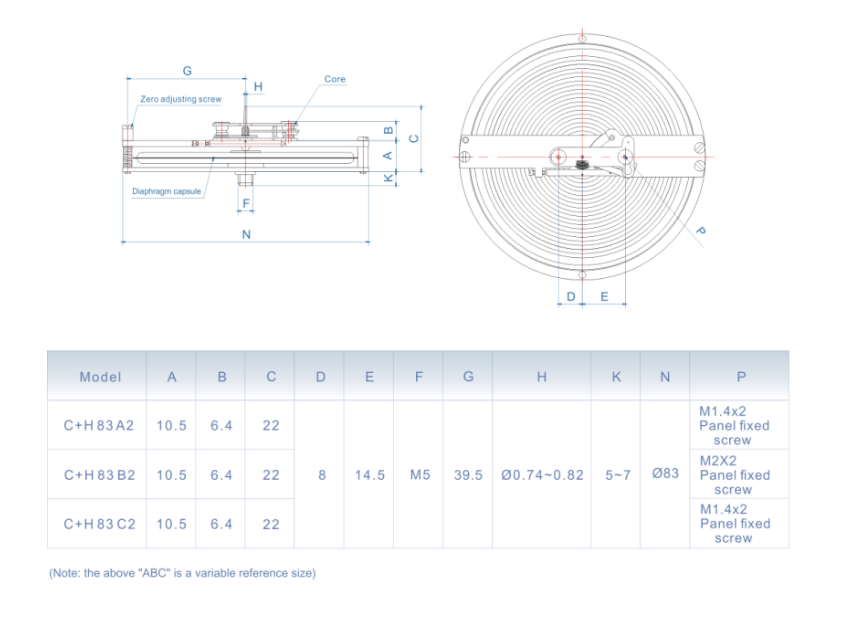

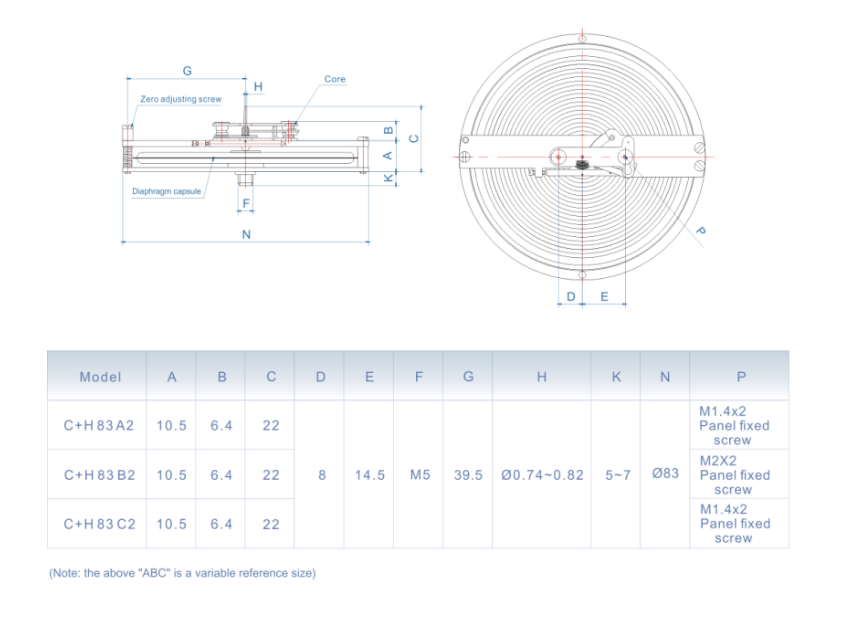

ODM Diaphragm Vacuum Pressure Gauge for precise measurement.

Understanding ODM Diaphragm Vacuum Pressure Gauges Precision Meets Performance

In the world of industrial instrumentation, precision and reliability are paramount, especially when it comes to measuring vacuum pressure. One such device that has gained significant traction is the ODM (Original Design Manufacturer) diaphragm vacuum pressure gauge. This innovative tool plays a crucial role in various applications, from chemical processing to automotive engineering, where accurate pressure measurement is essential.

An ODM diaphragm vacuum pressure gauge is a specialized instrument designed to measure the pressure within a vacuum system. The term 'ODM' refers to a company that designs and manufactures products specifically tailored to a client's specifications. In this context, ODM diaphragm gauges offer custom-designed solutions for precise pressure monitoring needs.

The heart of an ODM diaphragm gauge lies in its diaphragm, a flexible membrane that deforms in response to changes in pressure. When vacuum pressure acts on the diaphragm, it deflects, and this deflection is translated into a measurable indication of the pressure. The diaphragm design ensures high sensitivity, making it ideal for low-pressure measurements, a key requirement in vacuum systems.

The accuracy of ODM diaphragm vacuum pressure gauges can be attributed to their construction. These gauges often feature stainless steel diaphragms, ensuring durability and resistance to harsh environments. They also incorporate advanced materials and manufacturing techniques, enhancing their performance and longevity They also incorporate advanced materials and manufacturing techniques, enhancing their performance and longevity They also incorporate advanced materials and manufacturing techniques, enhancing their performance and longevity They also incorporate advanced materials and manufacturing techniques, enhancing their performance and longevity

They also incorporate advanced materials and manufacturing techniques, enhancing their performance and longevity They also incorporate advanced materials and manufacturing techniques, enhancing their performance and longevity odm diaphragm vacuum pressure gauge. The ODM approach allows for customization, with options for different pressure ranges, connections, and display types, meeting the unique requirements of each application.

One of the primary advantages of ODM diaphragm gauges is their ability to operate in hazardous or corrosive conditions. Their hermetically sealed design prevents contamination and ensures reliable performance even in extreme conditions. Moreover, their compact size and lightweight construction make them suitable for installation in tight spaces, adding to their versatility.

In addition to their technical prowess, ODM diaphragm vacuum pressure gauges contribute significantly to process efficiency and safety. Accurate pressure measurement is vital in processes like vacuum distillation, vacuum casting, and vacuum insulation, where slight deviations can lead to significant consequences. By providing real-time data, these gauges enable operators to make informed decisions, prevent equipment damage, and maintain process integrity.

In conclusion, ODM diaphragm vacuum pressure gauges represent a fusion of precision engineering and customized solutions. Their unique design, durability, and adaptability make them indispensable tools in industries that rely on precise vacuum pressure measurement. As technology continues to evolve, we can expect further advancements in ODM diaphragm gauges, pushing the boundaries of accuracy and performance even further.

odm diaphragm vacuum pressure gauge. The ODM approach allows for customization, with options for different pressure ranges, connections, and display types, meeting the unique requirements of each application.

One of the primary advantages of ODM diaphragm gauges is their ability to operate in hazardous or corrosive conditions. Their hermetically sealed design prevents contamination and ensures reliable performance even in extreme conditions. Moreover, their compact size and lightweight construction make them suitable for installation in tight spaces, adding to their versatility.

In addition to their technical prowess, ODM diaphragm vacuum pressure gauges contribute significantly to process efficiency and safety. Accurate pressure measurement is vital in processes like vacuum distillation, vacuum casting, and vacuum insulation, where slight deviations can lead to significant consequences. By providing real-time data, these gauges enable operators to make informed decisions, prevent equipment damage, and maintain process integrity.

In conclusion, ODM diaphragm vacuum pressure gauges represent a fusion of precision engineering and customized solutions. Their unique design, durability, and adaptability make them indispensable tools in industries that rely on precise vacuum pressure measurement. As technology continues to evolve, we can expect further advancements in ODM diaphragm gauges, pushing the boundaries of accuracy and performance even further.

They also incorporate advanced materials and manufacturing techniques, enhancing their performance and longevity They also incorporate advanced materials and manufacturing techniques, enhancing their performance and longevity

They also incorporate advanced materials and manufacturing techniques, enhancing their performance and longevity They also incorporate advanced materials and manufacturing techniques, enhancing their performance and longevity odm diaphragm vacuum pressure gauge. The ODM approach allows for customization, with options for different pressure ranges, connections, and display types, meeting the unique requirements of each application.

One of the primary advantages of ODM diaphragm gauges is their ability to operate in hazardous or corrosive conditions. Their hermetically sealed design prevents contamination and ensures reliable performance even in extreme conditions. Moreover, their compact size and lightweight construction make them suitable for installation in tight spaces, adding to their versatility.

In addition to their technical prowess, ODM diaphragm vacuum pressure gauges contribute significantly to process efficiency and safety. Accurate pressure measurement is vital in processes like vacuum distillation, vacuum casting, and vacuum insulation, where slight deviations can lead to significant consequences. By providing real-time data, these gauges enable operators to make informed decisions, prevent equipment damage, and maintain process integrity.

In conclusion, ODM diaphragm vacuum pressure gauges represent a fusion of precision engineering and customized solutions. Their unique design, durability, and adaptability make them indispensable tools in industries that rely on precise vacuum pressure measurement. As technology continues to evolve, we can expect further advancements in ODM diaphragm gauges, pushing the boundaries of accuracy and performance even further.

odm diaphragm vacuum pressure gauge. The ODM approach allows for customization, with options for different pressure ranges, connections, and display types, meeting the unique requirements of each application.

One of the primary advantages of ODM diaphragm gauges is their ability to operate in hazardous or corrosive conditions. Their hermetically sealed design prevents contamination and ensures reliable performance even in extreme conditions. Moreover, their compact size and lightweight construction make them suitable for installation in tight spaces, adding to their versatility.

In addition to their technical prowess, ODM diaphragm vacuum pressure gauges contribute significantly to process efficiency and safety. Accurate pressure measurement is vital in processes like vacuum distillation, vacuum casting, and vacuum insulation, where slight deviations can lead to significant consequences. By providing real-time data, these gauges enable operators to make informed decisions, prevent equipment damage, and maintain process integrity.

In conclusion, ODM diaphragm vacuum pressure gauges represent a fusion of precision engineering and customized solutions. Their unique design, durability, and adaptability make them indispensable tools in industries that rely on precise vacuum pressure measurement. As technology continues to evolve, we can expect further advancements in ODM diaphragm gauges, pushing the boundaries of accuracy and performance even further. Share

Latest news

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025