Dec . 10, 2024 23:56 Back to list

Diaphragm Seal Manifold Pressure Gauge for Accurate ODM Measurements

Understanding ODM Pressure Gauges with Diaphragm Seal and Manifold

In various industrial applications, precise pressure measurement is crucial for ensuring safety, efficiency, and operational integrity. One of the key components in achieving accurate pressure readings is the pressure gauge, specifically the ODM (Oil and Diaphragm Manifold) pressure gauge with a diaphragm seal. This article explores the features, functionalities, and applications of these specialized instruments.

What is an ODM Pressure Gauge?

An ODM pressure gauge is designed to measure pressure in systems where a direct connection to the fluid is either impractical or impossible. This could be due to high temperatures, corrosive media, or the need for isolation from the environment. The gauge combines the functionality of a diaphragm seal and a manifold, making it versatile and protective of sensitive measuring devices.

Diaphragm Seal Mechanism

The diaphragm seal is a crucial component of the ODM pressure gauge. It consists of a flexible membrane that separates the measurement chamber from the media being measured. When pressure is applied to the process fluid, it exerts force on the diaphragm, causing it to deform. This deformation is transmitted to the gauge mechanism, typically via a fill fluid, allowing for an accurate pressure reading.

The diaphragm seal is particularly advantageous in applications with corrosive or viscous fluids. By physically isolating the gauge from the fluid, it prevents damage to the gauge element, while also ensuring that the measurement is unaffected by the properties of the process fluid.

Features of ODM Pressure Gauges

1. Protection Against Corrosion ODM gauges are often made from materials that resist corrosion, such as stainless steel or special alloys. This ensures longevity and reliability in harsh environments.

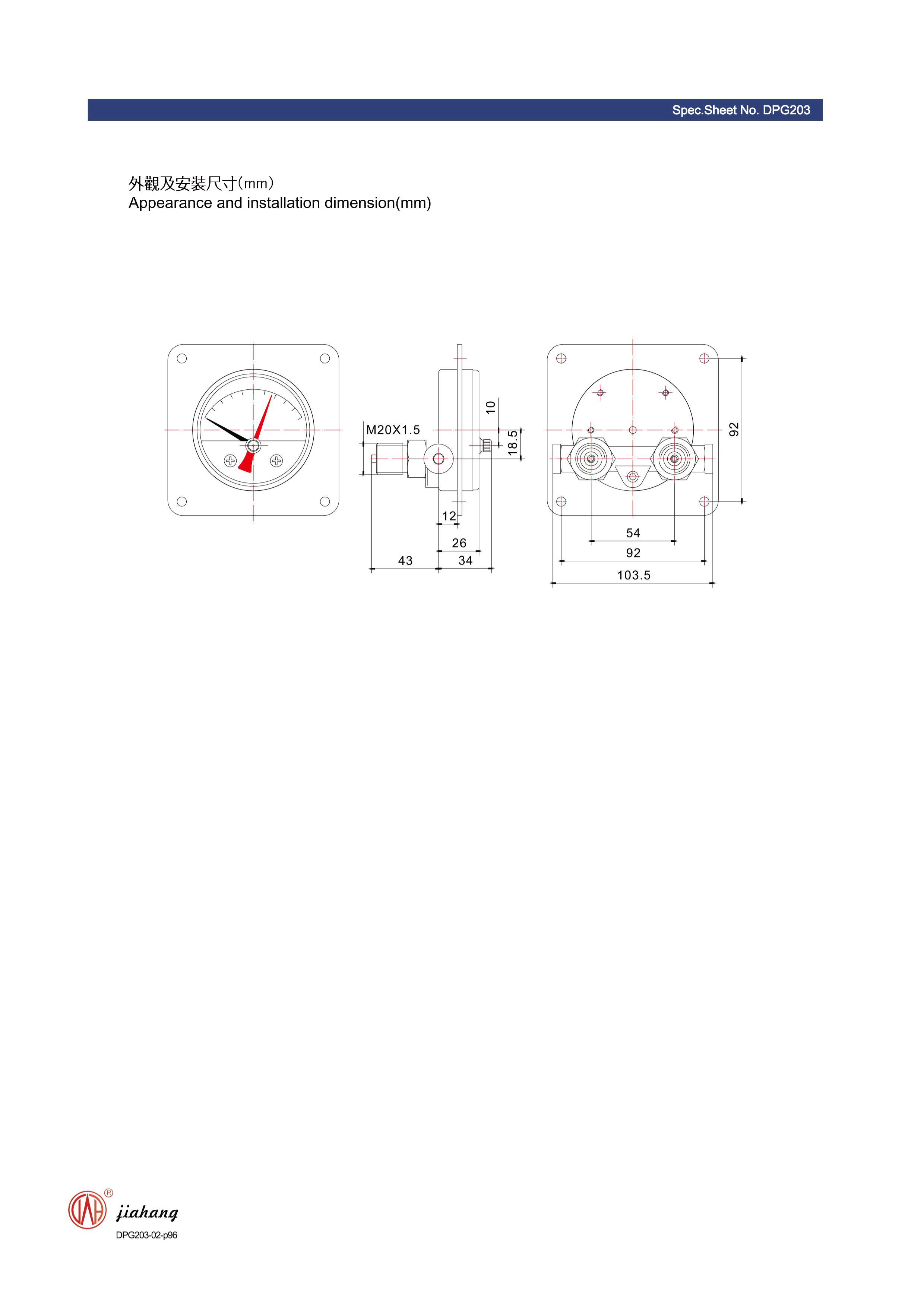

odm pressure gauge with diaphragm seal and manifold

3. Versatile Connection Options The manifold integrates various connection points for easy attachment to existing piping systems, allowing for multiple measurement and monitoring points.

4. Fill Fluid Choices The fill fluid used in the gauge plays a vital role in performance. It not only helps in the transfer of pressure from the diaphragm to the gauge but also provides thermal protection and dampening for pulsating pressures.

Applications of ODM Pressure Gauges

ODM pressure gauges with diaphragm seals and manifolds find applications across a broad spectrum of industries, including

- Chemical Processing In the chemical industry, precise pressure measurement is vital for reaction control and safety. The diaphragm seal protects the gauge from aggressive chemicals and high-pressure environments.

- Oil and Gas These gauges are commonly used in oil and gas operations where they can withstand high pressures and temperatures, ensuring accurate readings while avoiding direct exposure to the process fluid.

- Pharmaceuticals In pharmaceutical manufacturing, maintaining the integrity of the process is paramount. ODM gauges help in ensuring that pressure levels remain within specified limits, thus aiding in compliance with stringent industry regulations.

- Food and Beverage In food processing, where hygiene and safety are critical, diaphragm seals prevent contamination and ensure that the pressure monitoring does not compromise product quality.

Conclusion

The ODM pressure gauge with diaphragm seal and manifold is a powerful tool in the arsenal of industrial measurement instruments. Its ability to deliver accurate, reliable pressure readings in challenging environments makes it invaluable across various sectors. As industries continue to evolve and face new challenges, adopting advanced technologies like ODM gauges will be essential for maintaining operational efficiency and safety standards. By understanding and utilizing these tools, businesses can improve their processes and ensure they remain at the forefront of their respective fields.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025