Nov . 01, 2024 08:18 Back to list

Remote Diaphragm Seal Pressure Gauge for Accurate Measurements and Reliability in Harsh Environments

The Role of ODM Remote Diaphragm Seal Pressure Gauges in Industrial Applications

In the realm of industrial measurement, pressure gauges are crucial for monitoring and maintaining system integrity

. Among these, the ODM remote diaphragm seal pressure gauge has emerged as a preferred choice in various challenging environments. These gauges offer a unique solution designed to protect sensitive measuring elements from damaging effects such as high temperatures, corrosive fluids, and hazardous conditions.The primary function of a pressure gauge is to measure pressure levels within a system; however, traditional gauges can be vulnerable when exposed to extreme conditions. This is where the ODM remote diaphragm seal pressure gauge comes into play. Featuring a diaphragm that separates the pressure sensor from the process fluid, these gauges effectively prevent contamination and ensure accurate readings. The diaphragm, typically made from robust materials such as stainless steel or Hastelloy, can withstand corrosive and high-pressure environments, providing a reliable barrier against aggressive media.

One of the key advantages of the ODM design is its ability to eliminate the potential for damage to the pressure sensing element, which can lead to costly downtime and maintenance. The remote aspect of the diaphragm seal allows for installation away from the fluid or gas being measured, mitigating risks associated with high temperatures or chemicals at the sensing point. This separation not only enhances the gauge’s lifespan but also improves safety by minimizing the risk of leaks in hazardous applications.

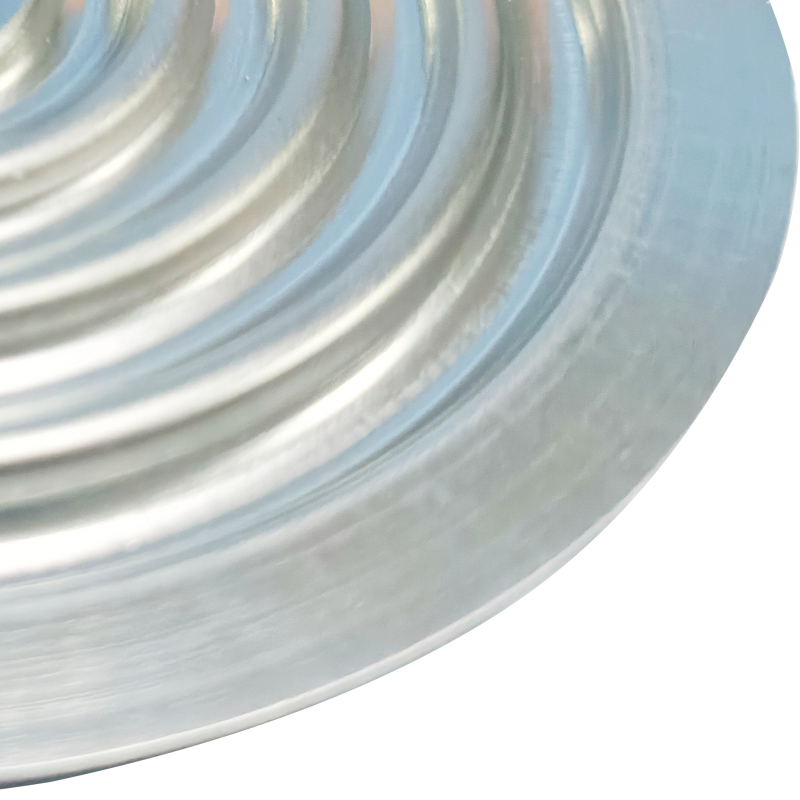

odm remote diaphragm seal pressure gauge

Additionally, ODM remote diaphragm seal pressure gauges are highly versatile and can be used in various industries, including oil and gas, chemical processing, pharmaceuticals, and food and beverage. In these sectors, maintaining precision is paramount, and the ODM design is capable of providing accurate and repeatable pressure readings under varying conditions.

Installation and maintenance of these gauges are straightforward, making them user-friendly options for operators. Their compact size and adaptable mounting options allow for ease of integration into existing systems, while their robust design ensures they can endure harsh operational environments.

To sum up, the ODM remote diaphragm seal pressure gauge stands out as an essential component for effective pressure monitoring in industrial applications. By providing accurate measurements while safeguarding against potential damage, these gauges ensure operational efficiency, safety, and reliability. As industries continue to evolve and face new challenges, the demand for such advanced pressure measurement solutions is likely to grow, further cementing the role of ODM remote diaphragm seal technology in contemporary operations.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025