Dec . 22, 2024 00:55 Back to list

odm span differential pressure gauge

Understanding ODM Span Differential Pressure Gauge

In industrial applications, pressure measurement is crucial for ensuring the efficient operation of various systems. One specific type of pressure measurement device that has gained attention is the ODM span differential pressure gauge. This instrument plays a vital role in numerous sectors, including oil and gas, water treatment, HVAC systems, and manufacturing processes. This article delves into the functions, benefits, and applications of the ODM span differential pressure gauge.

What is a Differential Pressure Gauge?

A differential pressure gauge measures the difference in pressure between two points in a system. This variance is essential for monitoring processes where pressure discrepancies can indicate potential issues, such as blockages in pipes, filter conditions, or variations in flow rates. The ODM span differential pressure gauge is a sophisticated variation that provides a more nuanced level of measurement, particularly in applications where precision is paramount.

Features of ODM Span Differential Pressure Gauge

1. High Accuracy One of the standout features of the ODM span differential pressure gauge is its high degree of accuracy. The gauge is designed to minimize errors, providing reliable readings that are critical for maintaining system integrity.

2. Wide Measurement Range Depending on the specific model, ODM gauges can measure a range of pressures. This versatility makes them suitable for a variety of applications, from low-pressure systems to high-pressure industrial processes.

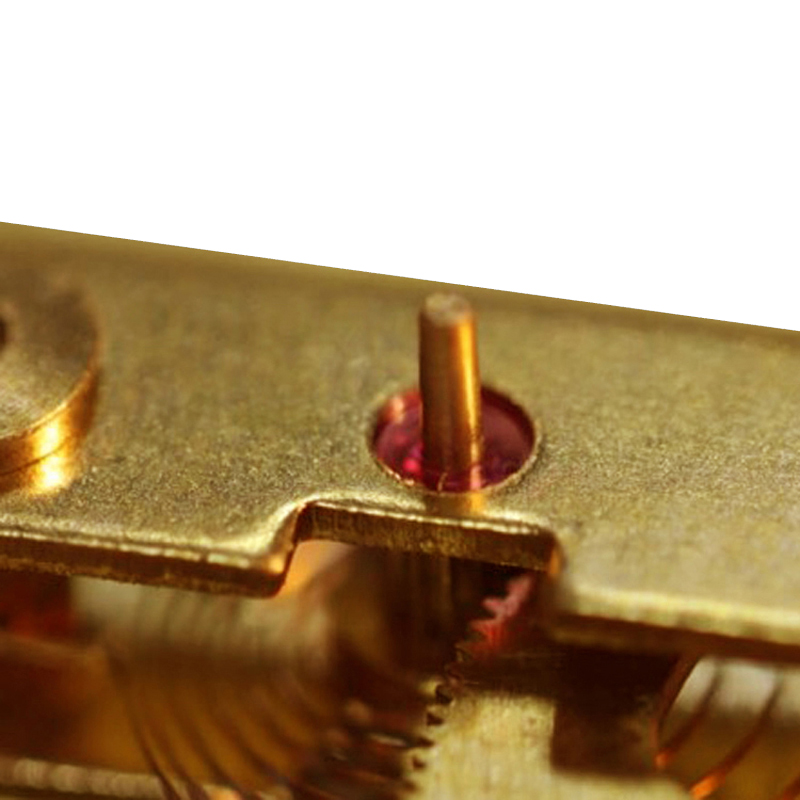

3. Robust Construction Given that many industrial environments can be harsh, ODM span differential pressure gauges are typically constructed from durable materials that can withstand corrosion, vibration, and temperature fluctuations.

4. Ease of Installation Most ODM gauges are designed for straightforward installation, minimizing downtime during setup. This user-friendly feature is especially beneficial in projects where time is of the essence.

5. Digital Technology Integration Modern ODM differential pressure gauges often incorporate digital technology, allowing for remote monitoring and data logging. This capability facilitates better process control and enables predictive maintenance strategies.

Benefits of Using ODM Span Differential Pressure Gauge

The implementation of ODM span differential pressure gauges offers numerous benefits

odm span differential pressure gauge

- Enhanced Process Control By continuously monitoring pressure differentials, operators can make informed decisions to optimize processes

. This leads to improved efficiency and reduced wastage.- Predictive Maintenance With the ability to track changes in differential pressure over time, businesses can identify potential maintenance issues before they escalate into costly failures.

- Increased Safety Accurate pressure measurement is paramount for safety. By utilizing ODM gauges, industries can ensure systems operate within safe pressure limits, thereby minimizing the risk of accidents.

- Cost-Effectiveness While the initial investment in high-quality instruments may be higher, the long-term savings gained from improved efficiency and reduced downtime make ODM span differential pressure gauges a worthwhile investment.

Applications in Various Industries

The ODM span differential pressure gauge has a diverse range of applications across different industries

- Oil and Gas In the oil and gas sector, these gauges are utilized to monitor pressure drops across filters and separators, ensuring the smooth operation of the extraction and refining processes.

- Water Treatment Differential pressure measurement is critical in water treatment plants to monitor the performance of filters and clarify the status of various stages in the purification process.

- HVAC Systems In heating, ventilation, and air conditioning systems, these gauges help monitor airflow and pressure variations, leading to improved energy efficiency and indoor air quality.

- Pharmaceutical Industry In controlled environments, maintaining specific pressure conditions is paramount. ODM gauges assist in monitoring differential pressure across systems to ensure compliance with regulatory standards.

Conclusion

The ODM span differential pressure gauge is an essential tool in modern industrial applications, providing high accuracy and reliability in pressure measurement. By enhancing process control, promoting predictive maintenance, and ensuring safety, these gauges play a crucial role in the efficiency and effectiveness of various operations. Their versatility and robust design make them indispensable across multiple sectors, demonstrating their value in the realm of industrial pressure measurement. As industries continue to advance, the significance of precision instruments like the ODM span differential pressure gauge will undoubtedly increase.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025