Nov . 25, 2024 00:02 Back to list

Understanding ODM Diaphragm Seal Pressure Gauge Types and Their Applications

Understanding ODM Wika Diaphragm Seal Type Pressure Gauges

Pressure measurement is a critical aspect of many industrial processes. To ensure accuracy and reliability in challenging environments, the ODM Wika diaphragm seal type pressure gauge offers a robust solution. This type of pressure gauge is designed to provide precise readings while protecting sensitive components from corrosive, viscous, or high-temperature media.

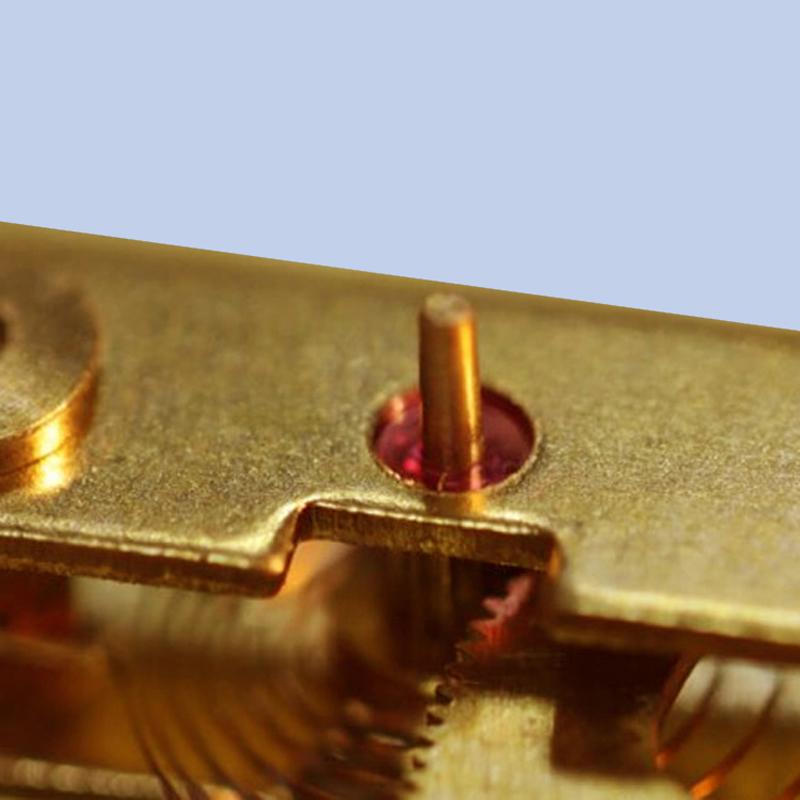

A diaphragm seal pressure gauge typically consists of a pressure gauge connected to a diaphragm seal. The diaphragm is a flexible membrane that separates the process media from the pressure sensing element of the gauge. This separation is crucial for applications where the pressure medium is aggressive or may damage the gauge itself. By utilizing a diaphragm, the gauge remains operational and maintains its accuracy, extending the lifespan of the equipment.

One of the key benefits of the ODM Wika diaphragm seal type pressure gauge is its versatility. It can be used in various industries, including chemical processing, pharmaceuticals, food and beverage, and oil and gas. The ability to handle different types of media makes it an ideal choice for applications where traditional pressure gauges may fail. For instance, in the chemical industry, where corrosive liquids and gases are common, a diaphragm seal gauge can provide reliable measurement without the risk of contamination or damage to the gauge.

Another important advantage of this type of gauge is its ability to accommodate high temperatures and pressures. ODM Wika offers gauges that can withstand extreme conditions, ensuring consistent performance even in harsh environments. The diaphragm's design allows it to effectively transmit pressure changes without being affected by temperature fluctuations or mechanical vibrations, providing accurate data for operators.

odm wika diaphragm seal type pressure gauge

Installation and maintenance are also important considerations when selecting a pressure gauge. The ODM Wika diaphragm seal type pressure gauge is designed for easy installation, often featuring threaded connections or flanges that adapt to various pipelines and systems. Maintenance practices are streamlined, as the gauge can be serviced without having to dismantle the entire system, thus minimizing downtime.

In terms of construction, the ODM Wika diaphragm seal type pressure gauge is built from durable materials that resist corrosion and wear. Common materials include stainless steel and various alloys tailored to withstand specific environments. This robust construction ensures that the gauge can endure the rigors of industrial applications while providing reliable performance.

The accuracy of the readings provided by the ODM Wika diaphragm seal type pressure gauge is vital. Companies depend on precise pressure measurements to optimize processes, ensure safety, and comply with regulatory standards. The diaphragm mechanism allows for immediate responses to pressure changes, enabling operators to make timely decisions based on accurate data.

In conclusion, the ODM Wika diaphragm seal type pressure gauge is an essential tool for accurate pressure measurement in challenging environments. Its robust design, ability to handle various media, and ease of installation and maintenance make it a versatile solution across many industries. By incorporating this technology, businesses can enhance operational efficiency, ensure safety, and maintain the integrity of their systems, ultimately leading to improved productivity and cost savings.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025