Jun . 13, 2024 11:02 Back to list

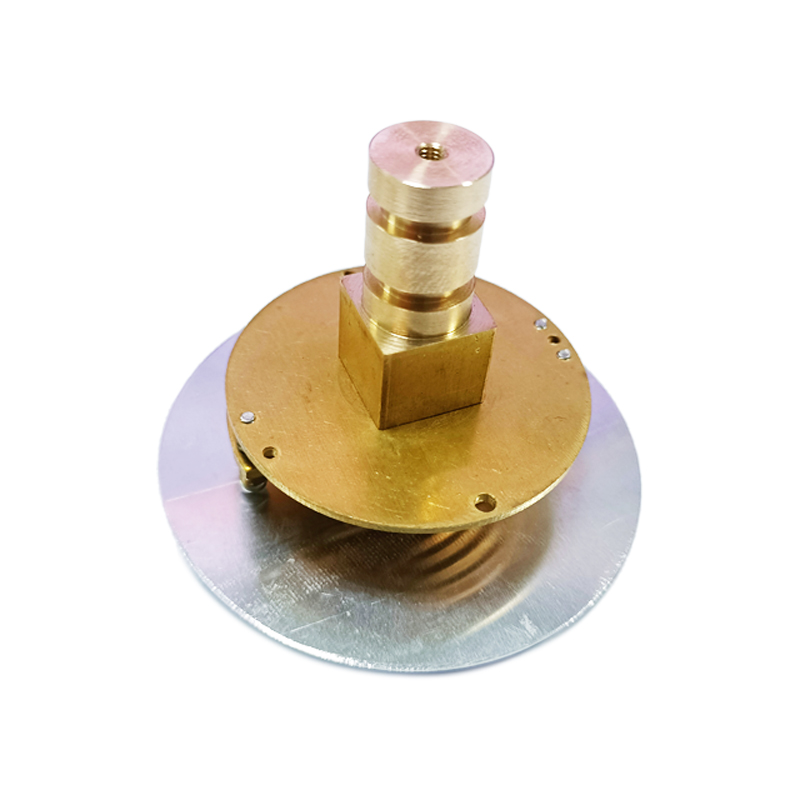

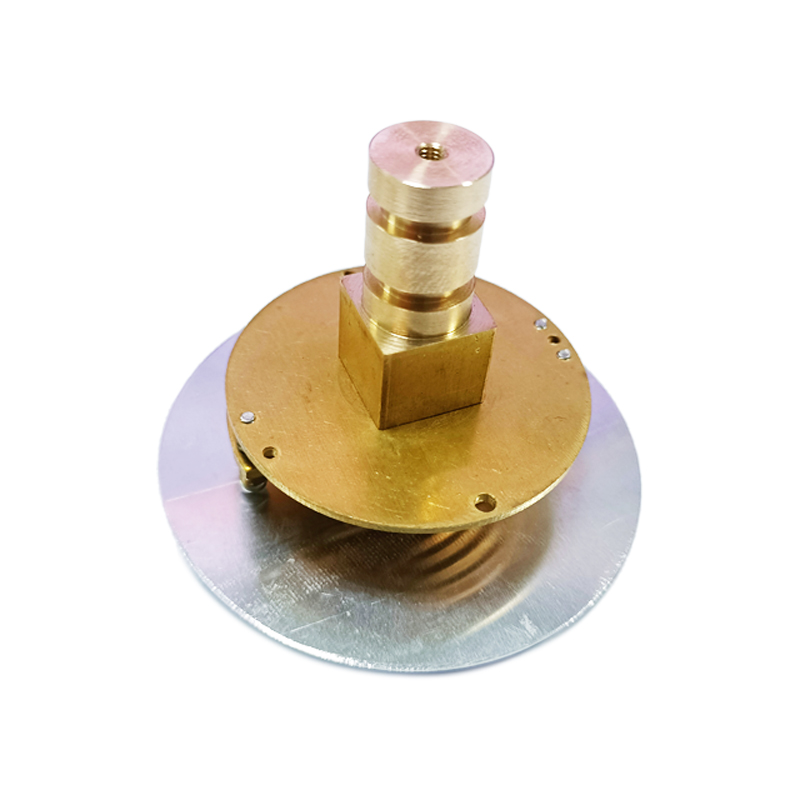

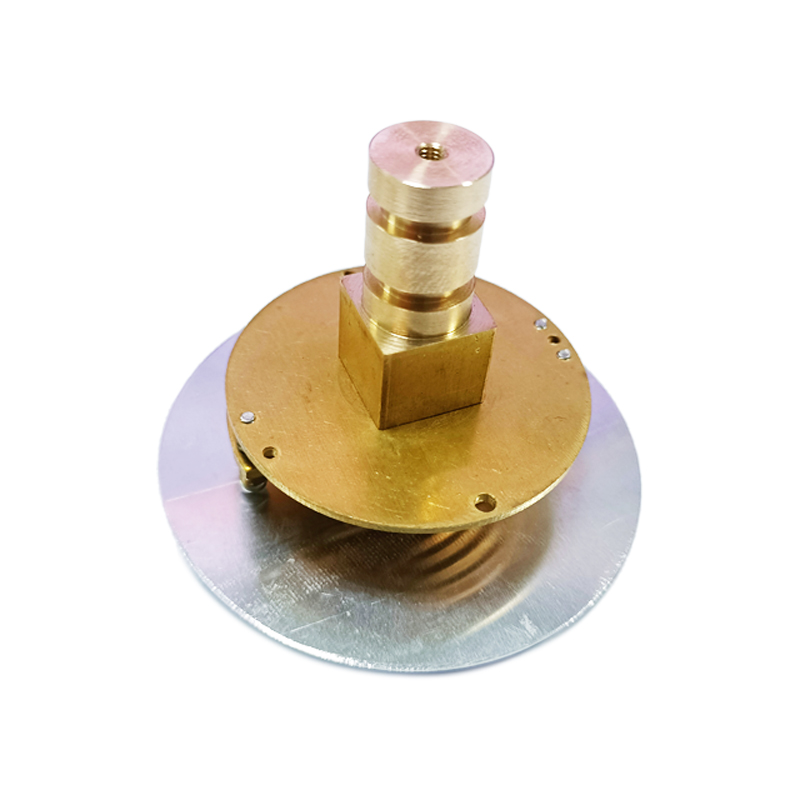

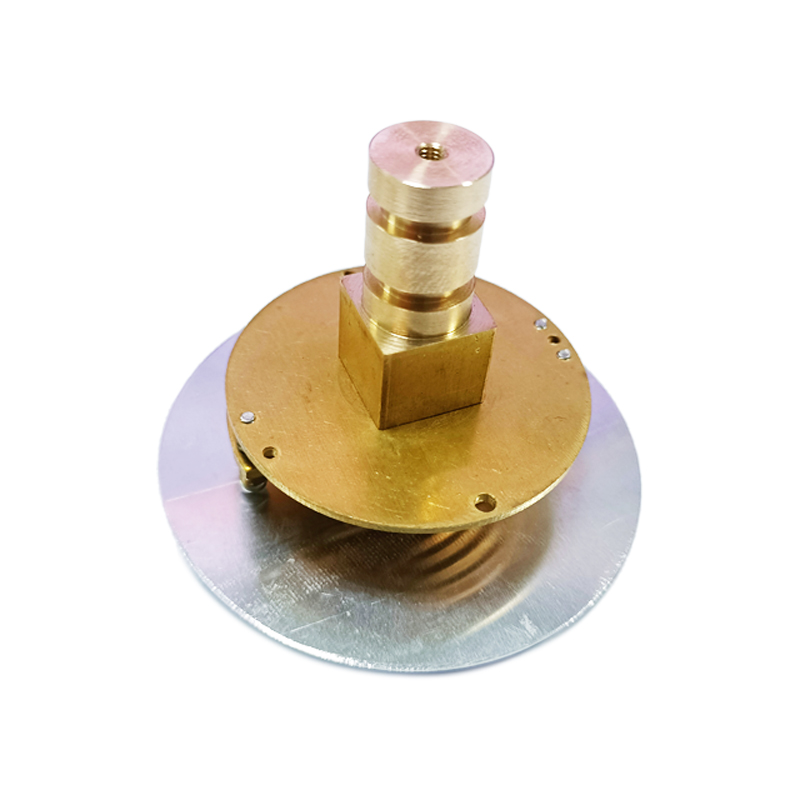

OEM-designed differential pressure gauge for monitoring pressure variations

Understanding the OEM Differential Pressure Gauge A Key Component in Industrial Monitoring

An Original Equipment Manufacturer (OEM) differential pressure gauge is an essential tool in various industrial applications where precise measurement of pressure differences is critical. It is designed to monitor and indicate the difference in pressure between two points in a system, providing vital data for process control and safety management.

The core principle of a differential pressure gauge lies in its ability to measure the disparity between high and low-pressure zones. It typically consists of two pressure ports, one for each side of the system, connected to a mechanism that translates these pressures into a readable output. This output can be analog, digital, or even remotely transmitted, depending on the specific OEM design.

In the context of an OEM setup, these gauges are customized to meet the unique requirements of the equipment or machinery they are integrated with. They are built to withstand harsh environments, endure extreme temperatures, and maintain accuracy over time, ensuring optimal performance and reliability. Their robust construction and precision engineering make them suitable for applications in industries such as oil and gas, chemical processing, water treatment, and HVAC systems.

One key advantage of an OEM differential pressure gauge is its versatility. It can be used to monitor filter performance by measuring the pressure drop across it, indicating when a filter needs changing. In fluid flow measurement, it helps determine the rate of flow by measuring the pressure difference across a restriction In fluid flow measurement, it helps determine the rate of flow by measuring the pressure difference across a restriction In fluid flow measurement, it helps determine the rate of flow by measuring the pressure difference across a restriction In fluid flow measurement, it helps determine the rate of flow by measuring the pressure difference across a restriction

In fluid flow measurement, it helps determine the rate of flow by measuring the pressure difference across a restriction In fluid flow measurement, it helps determine the rate of flow by measuring the pressure difference across a restriction oem differential pressure gauge. It also plays a crucial role in level measurement, particularly in tanks or vessels, by assessing the pressure difference caused by the height of the liquid.

The significance of accurate pressure measurement cannot be overstated. It ensures efficient operation, prevents equipment damage, and maintains safety standards. For instance, in pressure-sensitive processes like boiler operations, a differential pressure gauge can prevent overpressure situations that could lead to explosions.

In conclusion, the OEM differential pressure gauge is more than just a monitoring device; it's a safeguard for operational efficiency and safety. Its importance lies in its ability to provide real-time, accurate data, enabling engineers to make informed decisions and prevent potential issues before they escalate. As technology advances, so do these gauges, with digital and smart versions offering additional features like data logging and remote monitoring. Thus, the OEM differential pressure gauge remains a cornerstone in industrial instrumentation, continuously evolving to meet the demands of modern industry.

oem differential pressure gauge. It also plays a crucial role in level measurement, particularly in tanks or vessels, by assessing the pressure difference caused by the height of the liquid.

The significance of accurate pressure measurement cannot be overstated. It ensures efficient operation, prevents equipment damage, and maintains safety standards. For instance, in pressure-sensitive processes like boiler operations, a differential pressure gauge can prevent overpressure situations that could lead to explosions.

In conclusion, the OEM differential pressure gauge is more than just a monitoring device; it's a safeguard for operational efficiency and safety. Its importance lies in its ability to provide real-time, accurate data, enabling engineers to make informed decisions and prevent potential issues before they escalate. As technology advances, so do these gauges, with digital and smart versions offering additional features like data logging and remote monitoring. Thus, the OEM differential pressure gauge remains a cornerstone in industrial instrumentation, continuously evolving to meet the demands of modern industry.

In fluid flow measurement, it helps determine the rate of flow by measuring the pressure difference across a restriction In fluid flow measurement, it helps determine the rate of flow by measuring the pressure difference across a restriction

In fluid flow measurement, it helps determine the rate of flow by measuring the pressure difference across a restriction In fluid flow measurement, it helps determine the rate of flow by measuring the pressure difference across a restriction oem differential pressure gauge. It also plays a crucial role in level measurement, particularly in tanks or vessels, by assessing the pressure difference caused by the height of the liquid.

The significance of accurate pressure measurement cannot be overstated. It ensures efficient operation, prevents equipment damage, and maintains safety standards. For instance, in pressure-sensitive processes like boiler operations, a differential pressure gauge can prevent overpressure situations that could lead to explosions.

In conclusion, the OEM differential pressure gauge is more than just a monitoring device; it's a safeguard for operational efficiency and safety. Its importance lies in its ability to provide real-time, accurate data, enabling engineers to make informed decisions and prevent potential issues before they escalate. As technology advances, so do these gauges, with digital and smart versions offering additional features like data logging and remote monitoring. Thus, the OEM differential pressure gauge remains a cornerstone in industrial instrumentation, continuously evolving to meet the demands of modern industry.

oem differential pressure gauge. It also plays a crucial role in level measurement, particularly in tanks or vessels, by assessing the pressure difference caused by the height of the liquid.

The significance of accurate pressure measurement cannot be overstated. It ensures efficient operation, prevents equipment damage, and maintains safety standards. For instance, in pressure-sensitive processes like boiler operations, a differential pressure gauge can prevent overpressure situations that could lead to explosions.

In conclusion, the OEM differential pressure gauge is more than just a monitoring device; it's a safeguard for operational efficiency and safety. Its importance lies in its ability to provide real-time, accurate data, enabling engineers to make informed decisions and prevent potential issues before they escalate. As technology advances, so do these gauges, with digital and smart versions offering additional features like data logging and remote monitoring. Thus, the OEM differential pressure gauge remains a cornerstone in industrial instrumentation, continuously evolving to meet the demands of modern industry. Share

Latest news

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025