Feb . 01, 2025 05:37 Back to list

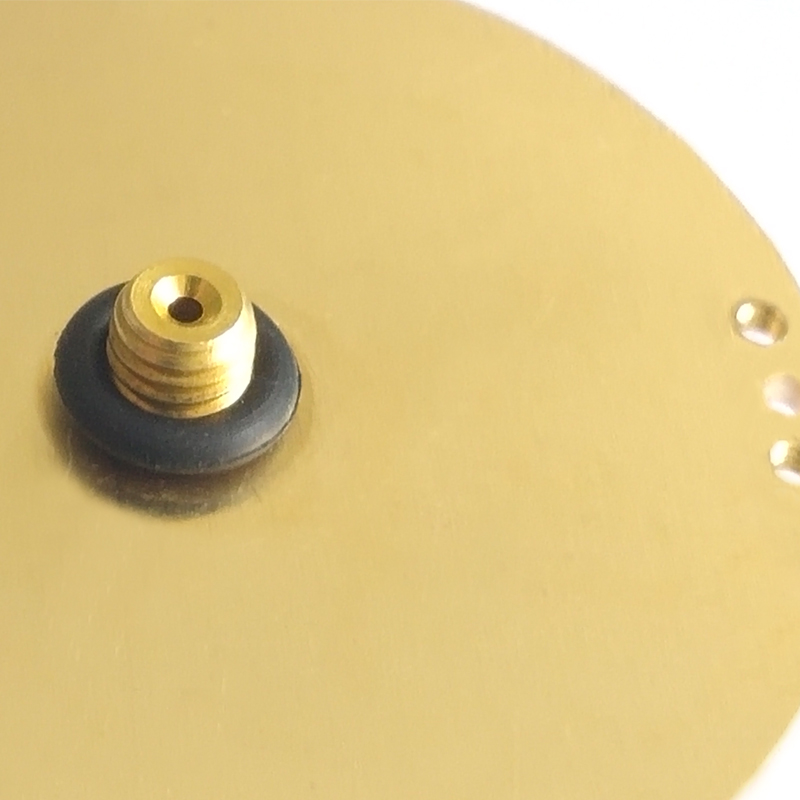

Capsule Pressure Gauge (CPG) -SS case, brass connection, WIKA type

In the realm of industrial applications and process instrumentation, precision is a crucial factor. Ensuring the reliable measurement of pressure, especially under extreme conditions, requires a sophisticated approach, and that's where OEM diaphragm seal pressure gauges come into play. These pressure gauges not only enhance accuracy but also offer critical protection and reliability, making them indispensable in various sectors.

Moreover, the role of maintenance and calibration in sustaining the accuracy of OEM diaphragm seal pressure gauges cannot be overstated. Regular calibration checks against reference standards ensure that the gauges continue to operate with the intended precision throughout their service life. Many OEM providers offer calibration services, along with detailed documentation, providing users with the peace of mind that their instrumentation is in peak operational condition. This ongoing support underscores the manufacturer's commitment to accuracy and reliability, further enhancing the gauge's trustworthiness. In addition to calibration, real-world experience with OEM diaphragm seal pressure gauges reveals their adaptability and resilience. Industries ranging from pharmaceuticals and petrochemicals to food processing and wastewater treatment have successfully implemented these gauges to monitor pressure with heightened accuracy. Feedback from field applications consistently highlights the increased operational efficiency and safety that these pressure gauges provide, a testament to their dependable performance. Understanding the critical nature of high precision in process industries, OEM diaphragm seal pressure gauges have become a symbol of reliability and expertise. Partnerships with experienced OEM manufacturers bring the assurance of high-quality design, innovation, and support, ensuring that each pressure gauge is fit for purpose, maximizing accuracy, and enhancing system safety and efficiency. In conclusion, the choice of an OEM diaphragm seal pressure gauge is an investment in accuracy, expertise, and reliability. It's a strategic decision that supports operational excellence by delivering precise pressure measurements amidst challenging environmental and process conditions. By combining cutting-edge design, rigorous calibration standards, and real-world reliability, these instruments exemplify the hallmarks of Experience, Expertise, Authoritativeness, and Trustworthiness—making them an indispensable asset in any industry where precision is paramount.

Moreover, the role of maintenance and calibration in sustaining the accuracy of OEM diaphragm seal pressure gauges cannot be overstated. Regular calibration checks against reference standards ensure that the gauges continue to operate with the intended precision throughout their service life. Many OEM providers offer calibration services, along with detailed documentation, providing users with the peace of mind that their instrumentation is in peak operational condition. This ongoing support underscores the manufacturer's commitment to accuracy and reliability, further enhancing the gauge's trustworthiness. In addition to calibration, real-world experience with OEM diaphragm seal pressure gauges reveals their adaptability and resilience. Industries ranging from pharmaceuticals and petrochemicals to food processing and wastewater treatment have successfully implemented these gauges to monitor pressure with heightened accuracy. Feedback from field applications consistently highlights the increased operational efficiency and safety that these pressure gauges provide, a testament to their dependable performance. Understanding the critical nature of high precision in process industries, OEM diaphragm seal pressure gauges have become a symbol of reliability and expertise. Partnerships with experienced OEM manufacturers bring the assurance of high-quality design, innovation, and support, ensuring that each pressure gauge is fit for purpose, maximizing accuracy, and enhancing system safety and efficiency. In conclusion, the choice of an OEM diaphragm seal pressure gauge is an investment in accuracy, expertise, and reliability. It's a strategic decision that supports operational excellence by delivering precise pressure measurements amidst challenging environmental and process conditions. By combining cutting-edge design, rigorous calibration standards, and real-world reliability, these instruments exemplify the hallmarks of Experience, Expertise, Authoritativeness, and Trustworthiness—making them an indispensable asset in any industry where precision is paramount.

Share

Latest news

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025