Nov . 20, 2024 00:31 Back to list

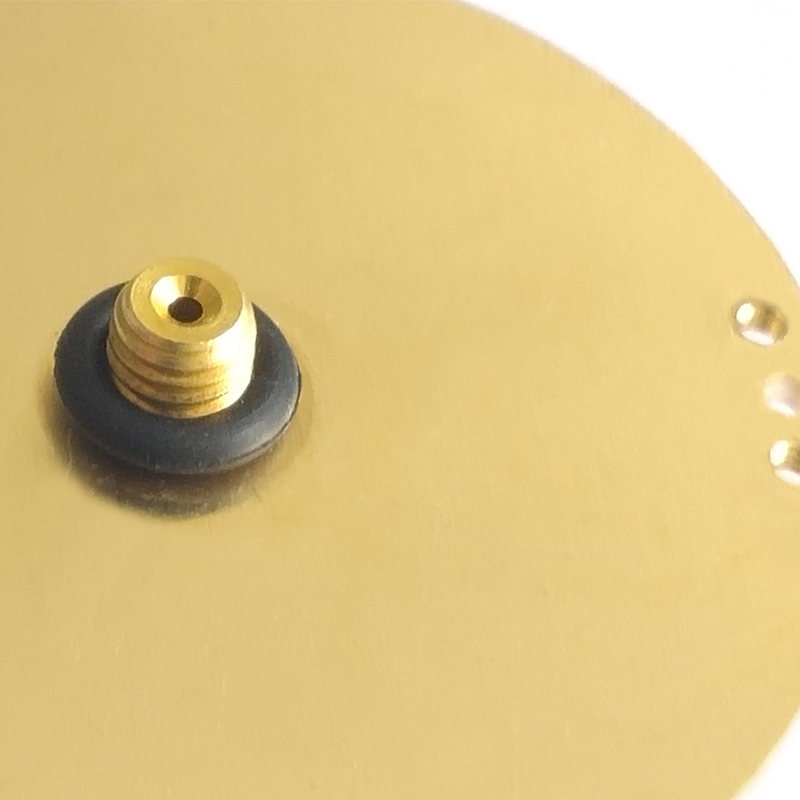

oem diaphragm type pressure gauge ashcroft

The Significance of OEM Diaphragm Type Pressure Gauges A Closer Look at Ashcroft Products

In industrial applications, monitoring pressure is essential for maintaining safety, efficiency, and the smooth operation of equipment. Pressure gauges are critical devices that help achieve this, and among the different types available, diaphragm-type pressure gauges stand out for their accuracy and reliability. One prominent manufacturer known for its high-quality pressure measurement solutions is Ashcroft. This article explores the importance of OEM diaphragm-type pressure gauges, focusing on those produced by Ashcroft.

Understanding Diaphragm Type Pressure Gauges

Diaphragm type pressure gauges utilize a flexible diaphragm to detect pressure changes within a system. When pressure is applied, the diaphragm bends, and this movement is translated into a readable measurement. Unlike traditional bourdon tube gauges, diaphragm gauges are particularly effective at measuring low-pressure ranges, making them ideal for various applications, including pharmaceuticals, food processing, and HVAC systems. The design and materials used in these gauges allow for superior performance in challenging conditions, such as those involving corrosive or viscous media.

The Role of OEM Manufacturers

OEM, or Original Equipment Manufacturer, refers to companies that produce parts and equipment that are used in another company's end product. In the context of diaphragm-type pressure gauges, OEMs like Ashcroft provide high-quality components that integrate seamlessly into various systems. The key advantages of using OEM products include consistency in quality, compatibility with existing equipment, and access to advanced technology that might not be available through generic parts.

Ashcroft A Leader in Pressure Measurement

Since its founding in the 1850s, Ashcroft has built a reputation for excellence in pressure measurement solutions. The company offers a comprehensive range of diaphragm-type pressure gauges designed to meet the needs of various industries. Ashcroft’s gauges are manufactured using premium materials, ensuring durability and accuracy even in extreme environments.

One noteworthy feature of Ashcroft diaphragm pressure gauges is their ability to provide accurate readings in applications with pulsating or fluctuating pressure. This capability is crucial for industries like oil and gas, where pressure conditions can change rapidly and dramatically. Furthermore, Ashcroft pressure gauges comply with various industry standards, making them a reliable choice for applications requiring certification or regulatory compliance.

Quality and Reliability

oem diaphragm type pressure gauge ashcroft

Quality is a cornerstone of Ashcroft’s manufacturing process. Each diaphragm gauge undergoes rigorous testing and calibration to ensure precision measurement. The use of advanced manufacturing techniques and state-of-the-art technology contributes to the reliability of Ashcroft products. These gauges are designed to withstand harsh conditions, including extreme temperatures, high vibrations, and corrosive substances, thus offering a prolonged service life.

Customizability

One of the significant advantages of working with OEM manufacturers like Ashcroft is the ability to customize products to meet specific customer requirements. Businesses in niche markets often have unique needs regarding size, range, and design. Ashcroft’s commitment to customer satisfaction means that they collaborate closely with clients to develop bespoke solutions that address specialized applications.

Applications of Ashcroft Diaphragm Type Pressure Gauges

The versatility of Ashcroft diaphragm-type pressure gauges means they find application in a wide range of industries

1. Pharmaceuticals In drug manufacturing, maintaining specific pressure levels is crucial for product quality and safety. Diaphragm gauges ensure precise control of various processes. 2. Food and Beverage Hygiene and safety are paramount in food production. Ashcroft gauges are designed with materials that meet stringent health regulations, ensuring product integrity.

3. HVAC Systems In heating, ventilation, and air conditioning systems, accurate pressure measurement is essential for energy efficiency and system reliability.

4. Oil and Gas In this sector, equipment must withstand harsh environments while providing consistent performance. Ashcroft gauges are built to operate under extreme conditions without compromising accuracy.

Conclusion

In conclusion, OEM diaphragm-type pressure gauges, particularly those produced by Ashcroft, play a vital role in various industries by ensuring accurate pressure monitoring. The combination of high-quality materials, rigorous testing, and the ability to customize adjusts makes Ashcroft a preferred choice for professionals seeking reliability and precision in pressure measurement. As industries continue to evolve and demand more efficient solutions, Ashcroft remains at the forefront, continually innovating to meet the needs of its diverse clientele. Whether in pharmaceuticals, food processing, or oil and gas, Ashcroft diaphragm pressure gauges are integral to operational success and safety.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025