Jan . 24, 2025 03:49 Back to list

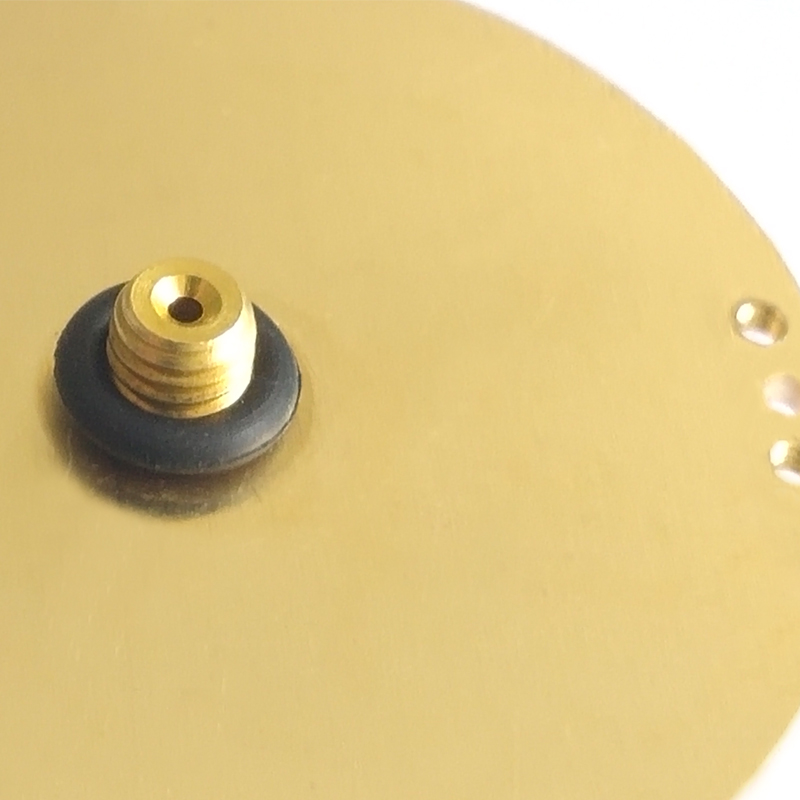

low pressure differential pressure gauge

In the competitive landscape of industrial instrumentation, OEM hydraulic differential pressure gauges have emerged as a crucial component for ensuring precision, efficiency, and reliability in various applications ranging from industrial hydraulics to automation systems. A deep dive into these instruments reveals their unparalleled benefits and the role they play in optimizing operations across multiple industries.

In practical applications, the importance of hydraulic differential pressure gauges can be seen in industries such as oil and gas, chemical processing, and HVAC systems. For instance, in the oil and gas industry, maintaining the exact pressure in pipelines is critical to prevent leaks and ensure safety. Here, differential pressure gauges provide essential data that helps operators make informed decisions and maintain constant surveillance over fluid transport systems. Similarly, in chemical processing, the reactivity of substances under varying pressure conditions necessitates precise pressure measurements to prevent dangerous reactions and maintain quality control. OEM differential pressure gauges provide the precision needed to ensure safe and efficient operation. Moreover, in HVAC systems, these gauges are integral in managing and optimizing air pressure across various sections of the intricate duct systems. This optimization not only enhances comfort and air quality but also contributes to energy efficiency, a growing concern in modern infrastructure. It’s clear that OEM hydraulic differential pressure gauges are not just instruments but are key enablers of operational success across multiple industries. Their role is crucial in maintaining the intricate balance of pressure in fluid systems, ultimately enhancing safety, reliability, and efficiency. As industries continue to evolve, the options provided by OEM manufacturers will likely expand, further integrating cutting-edge technology with industry-specific requirements. As companies look toward future-proofing their operations, investing in high-quality, reliable differential pressure gauges from authoritative OEM manufacturers will be a decisive factor in achieving sustainable and efficient system operations. The seamless integration of these gauges into complex industrial systems continues to demonstrate their invaluable contribution and necessity in the ongoing journey towards industrial excellence.

In practical applications, the importance of hydraulic differential pressure gauges can be seen in industries such as oil and gas, chemical processing, and HVAC systems. For instance, in the oil and gas industry, maintaining the exact pressure in pipelines is critical to prevent leaks and ensure safety. Here, differential pressure gauges provide essential data that helps operators make informed decisions and maintain constant surveillance over fluid transport systems. Similarly, in chemical processing, the reactivity of substances under varying pressure conditions necessitates precise pressure measurements to prevent dangerous reactions and maintain quality control. OEM differential pressure gauges provide the precision needed to ensure safe and efficient operation. Moreover, in HVAC systems, these gauges are integral in managing and optimizing air pressure across various sections of the intricate duct systems. This optimization not only enhances comfort and air quality but also contributes to energy efficiency, a growing concern in modern infrastructure. It’s clear that OEM hydraulic differential pressure gauges are not just instruments but are key enablers of operational success across multiple industries. Their role is crucial in maintaining the intricate balance of pressure in fluid systems, ultimately enhancing safety, reliability, and efficiency. As industries continue to evolve, the options provided by OEM manufacturers will likely expand, further integrating cutting-edge technology with industry-specific requirements. As companies look toward future-proofing their operations, investing in high-quality, reliable differential pressure gauges from authoritative OEM manufacturers will be a decisive factor in achieving sustainable and efficient system operations. The seamless integration of these gauges into complex industrial systems continues to demonstrate their invaluable contribution and necessity in the ongoing journey towards industrial excellence.

Share

Latest news

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025