Dec . 10, 2024 18:54 Back to list

OEM Wika Diaphragm Pressure Gauge Specifications and Applications Explained

Understanding OEM WIKA Diaphragm Pressure Gauges

In industrial applications, ensuring the accurate measurement of pressure is crucial for operational efficiency and safety. One of the leading technologies in pressure measurement is the diaphragm pressure gauge, particularly those manufactured by WIKA, a renowned name in the field of pressure and temperature measurement. This article will delve into the features, benefits, and applications of OEM WIKA diaphragm pressure gauges.

What is a Diaphragm Pressure Gauge?

A diaphragm pressure gauge is a type of pressure measurement device that utilizes a flexible diaphragm to sense pressure changes. When pressure is applied, the diaphragm bends, and this movement is translated into a dial reading by a mechanical linkage. Diaphragm gauges are particularly suited for measuring low to medium pressures, and they can be used in various applications where fluid compatibility and accuracy are paramount.

Benefits of WIKA Diaphragm Pressure Gauges

1. High Accuracy WIKA diaphragm pressure gauges are known for their exceptional accuracy. They utilize precision engineering to ensure that the readings are reliable, which is essential in critical processes.

2. Robust Construction One of the standout features of WIKA products is their durable construction. Made from high-quality materials, these gauges can withstand harsh industrial environments, including exposure to chemicals and extreme temperatures.

3. Wide Range of Applications OEM WIKA diaphragm pressure gauges are versatile and can be used in various industries, including oil and gas, food and beverage, pharmaceuticals, and water treatment. Their adaptability makes them a popular choice across sectors.

4. Liquid and Gas Measurement These gauges can measure both liquid and gas pressure, making them suitable for diverse applications. This dual functionality allows for streamlined operations and reduces the need for multiple types of gauges in a facility.

5. Customizable Options WIKA offers OEM solutions that allow for customization to meet specific needs. Features such as dial size, connection type, and material compatibility can be tailored according to the application, ensuring optimal performance.

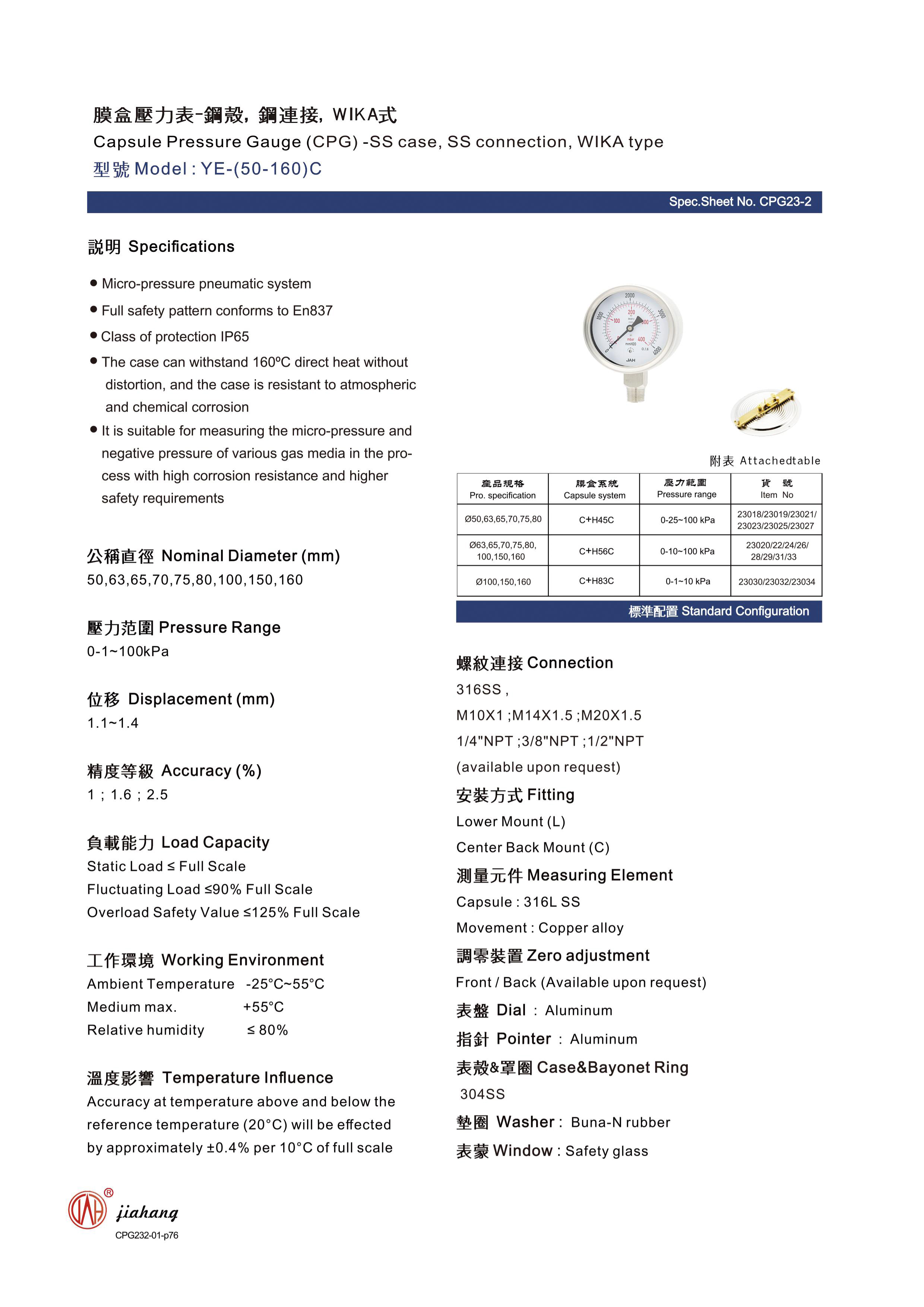

oem wika diaphragm pressure gauge

6. Maintenance-Free Unlike some traditional pressure measurement devices, diaphragm gauges often require minimal maintenance. Their robust design and construction mean less downtime and lower operational costs.

Applications of OEM WIKA Diaphragm Pressure Gauges

Diaphragm pressure gauges are employed in numerous applications due to their reliability and precise measurements

- Hydraulic Systems In hydraulic machinery, maintaining appropriate pressure levels is vital for performance. WIKA diaphragm gauges ensure accurate pressure readings, which help prevent equipment failure.

- Food Processing In food and beverage production, hygiene and safety standards are paramount. WIKA gauges can be designed with sanitary connections and materials that comply with industry regulations, making them ideal for this sector.

- Chemical Processing The chemical industry often deals with corrosive substances. WIKA’s diaphragm gauges can be made from materials that resist corrosion, safeguarding against leaks and ensuring safety during operations.

- Pharmaceuticals In pharmaceutical manufacturing, accurate pressure control is crucial for product quality and safety. WIKA diaphragm gauges can help monitor and maintain necessary pressure levels throughout various processes.

- Water Treatment Plants In water treatment facilities, these gauges assist in monitoring hydraulic pressure in filtration and distribution systems, contributing to efficient water management.

Conclusion

The OEM WIKA diaphragm pressure gauges exemplify advanced engineering and design dedicated to precision and reliability. Their wide range of applications and benefits makes them an indispensable tool across numerous industries. By choosing WIKA, businesses can enhance their operational efficiency, ensuring that processes run smoothly and safely. Whether you’re in the food industry, pharmaceuticals, or any sector requiring pressure measurement, WIKA diaphragm gauges provide the confidence needed for optimal performance and safety.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025