Dec . 29, 2024 01:20 Back to list

Pressure Gauge Manufacturing for Portable Fire Extinguishers and Safety Equipment

Understanding the Importance of Portable Fire Extinguisher Pressure Gauges

In a world where fire safety is paramount, the significance of portable fire extinguishers cannot be overstated. These devices are the first line of defense in case of an unexpected fire, serving to contain and extinguish flames before they escalate into a major disaster. A crucial component of ensuring the effectiveness of a portable fire extinguisher is the pressure gauge. This article delves into the role of pressure gauges, the manufacturing process, and their importance for both safety and compliance.

The Role of Pressure Gauges

The pressure gauge on a portable fire extinguisher is essential for determining whether the extinguisher is charged and ready for use. Fire extinguishers are typically pressurized with an inert gas, and the gauge provides a visual indication of the internal pressure. Most gauges include a color-coded area to denote the acceptable range of pressure; if the needle falls into the ‘red zone’, it indicates that the extinguisher is either over-pressurized or under-pressurized, both of which can render the device ineffective during an emergency.

Regular inspection of the pressure gauge is crucial. Fire extinguishers should be checked monthly to ensure that they are in operational condition. If the pressure is not within the adequate range, the extinguisher should be serviced or replaced. This preventive maintenance is essential in workplace safety protocols and can save lives.

Manufacturing Process of Pressure Gauges

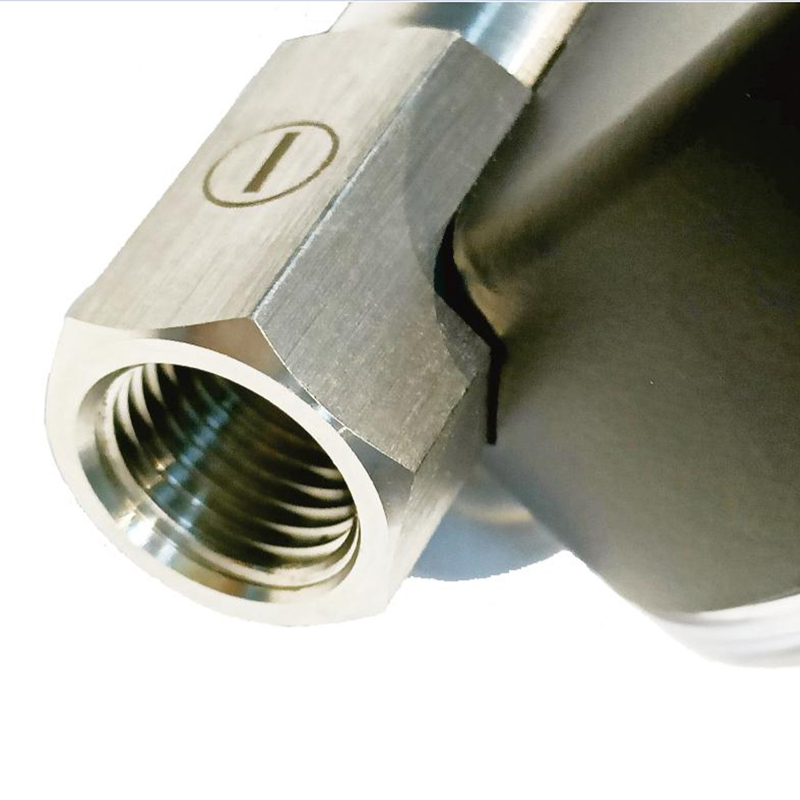

The manufacturing of portable fire extinguisher pressure gauges is a specialized process that involves precision engineering. Factories producing these gauges adhere to strict industry standards to ensure accuracy, reliability, and safety. The gauges are typically made with durable materials designed to withstand extreme pressure and environmental conditions.

portable fire extinguisher pressure gauge factories

The manufacturing process begins with the selection of high-quality materials, often stainless steel, which offers both durability and resistance to corrosion. The components, including the diaphragm and the Bourdon tube, are crafted to ensure precise measurement of the internal pressure of the extinguisher.

Once the components are assembled, each pressure gauge undergoes rigorous testing to verify its accuracy and reliability. These tests simulate various pressure levels to ensure that the gauge responds appropriately. Quality control is vital, as any malfunction in a fire extinguisher or its gauge can have catastrophic consequences.

Importance for Safety and Compliance

For businesses and homeowners alike, understanding the functionality of pressure gauges is vital for maintaining fire safety. Portable fire extinguishers equipped with accurate pressure gauges not only comply with local fire code regulations but also enhance overall safety. Regulatory agencies often mandate the presence of a functioning pressure gauge on fire extinguishers as part of safety inspections.

In addition to compliance, educating employees about how to read and interpret pressure gauges can further improve safety protocols. Training sessions can empower staff to take proactive measures, such as ensuring that fire extinguishers are serviced regularly and replaced when necessary.

Conclusion

In summary, portable fire extinguisher pressure gauges play a crucial role in fire safety. Their ability to provide immediate visual feedback on the operational status of an extinguisher can mean the difference between a contained fire and a full-blown emergency. Manufacturers that prioritize quality and precision in their gauge production foster a safer environment for everyone. By understanding and maintaining these vital components, individuals and businesses can ensure they are prepared for any fire-related incidents that may arise. Fire safety is not just a compliance requirement; it is a commitment to protecting lives and property.

-

High-Accuracy Differential Pressure Gauge Diaphragms OEM Factories & Services

NewsMay.24,2025

-

Water Fire Extinguisher Pressure Gauge Durable Supplier Solutions

NewsMay.24,2025

-

Handheld Digital Differential Pressure Gauge Portable, High-Accuracy & Real-Time Data

NewsMay.24,2025

-

Digital Pressure Gauge RS Components for Semiconductor & Chip Industries

NewsMay.23,2025

-

Industrial Differential Pressure Gauges Global Supplier & Pricelist

NewsMay.23,2025

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025