Dec . 25, 2024 17:08 Back to list

precision instrument pressure gauges company

Precision Instrument Pressure Gauges Ensuring Accuracy in Measurement

In various industrial and scientific applications, the need for accurate pressure measurements cannot be overstated. One of the key players in this domain is precision instrument pressure gauges. These instruments are not just tools; they are the lifelines of many processes, ensuring the safety, efficiency, and reliability of numerous systems.

Understanding Pressure Gauges

Pressure gauges are devices used to measure the pressure of gases or liquids within a system. They serve various industries, including oil and gas, pharmaceuticals, food and beverage, and manufacturing. A pressure gauge provides critical data that operators and engineers rely on to make informed decisions about system performance and safety.

Precision instrument pressure gauges are known for their high accuracy, durability, and reliability. They are designed to withstand harsh environmental conditions, making them suitable for both laboratory settings and rugged industrial environments. The ability to provide precise readings can significantly impact the quality of the product being manufactured or the safety of the operation being conducted.

Types of Pressure Gauges

There are several types of pressure gauges, each designed for specific applications.

1. Bourdon Tube Gauges These are the most common type. They consist of a curved tube that straightens as pressure increases. The movement of the tube is translated into a reading on a dial.

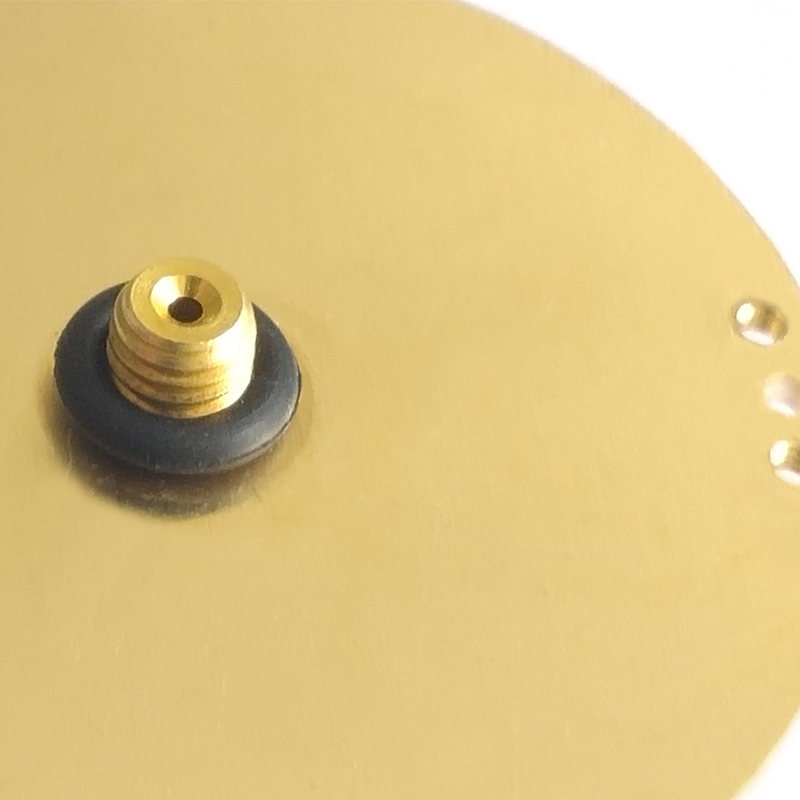

2. Diaphragm Gauges These use a flexible diaphragm which deforms under pressure. They are ideal for low-pressure measurements and are often used in the food and pharmaceutical industries.

3. Digital Pressure Gauges These provide electronic readings and can often be more accurate than mechanical gauges. They may feature data logging capabilities, making them useful for long-term monitoring.

precision instrument pressure gauges company

5. Absolute and Gauge Pressure Gauges Absolute gauges measure pressure relative to a perfect vacuum, while gauge pressure gauges measure pressure relative to the ambient atmospheric pressure.

Benefits of Precision Instrument Pressure Gauges

The benefits of using precision instrument pressure gauges are manifold. Firstly, accuracy is paramount in many industrial processes. An inaccurate pressure reading can lead to equipment failure, safety hazards, and financial losses. Precision gauges mitigate these risks by providing accurate, real-time data.

Secondly, they enhance process efficiency. By continuously monitoring pressure levels, operators can optimize processes, reduce waste, and improve product quality. For instance, in the oil and gas industry, accurate pressure readings can help prevent blowouts and leaks, leading to safer operations.

Additionally, precision gauges are designed for ease of use. Many modern gauges feature intuitive interfaces and digital displays, making it easier for operators to read and interpret data. This user-friendliness reduces the chances of human error and ensures that the right decisions are made quickly.

Applications of Precision Instrument Pressure Gauges

Precision instrument pressure gauges find applications across various sectors. In the oil and gas industry, they are used to monitor pipeline pressures, ensuring safe transport of fluids. In manufacturing, they help maintain optimal conditions in processes like molding and chemical reactions. The pharmaceutical industry relies on accurate pressure readings during the production of medications, where any deviation can result in ineffective or unsafe products.

Moreover, in the HVAC industry, pressure gauges play a crucial role in ensuring that heating and cooling systems operate efficiently. By measuring pressure throughout the system, technicians can identify blockages or leaks, allowing for timely maintenance.

Conclusion

Precision instrument pressure gauges are indispensable in today’s industrial landscape. They not only ensure the accuracy of pressure measurements but also contribute to the overall efficiency and safety of processes across various sectors. As technology continues to advance, the development of more sophisticated and reliable pressure gauges will play a critical role in enhancing operational efficiency and safety standards. Investing in high-quality precision pressure gauges is a wise decision for any industry aiming for excellence in performance and product quality. The importance of having accurate and reliable pressure measurement cannot be understated, as it plays a critical role in driving productivity and ensuring safety in numerous applications.

-

Top Diaphragm Seal Pressure Gauge Suppliers Precision & Durability

NewsMay.29,2025

-

Ashcroft Diaphragm Pressure Gauges High Accuracy & Durable Design

NewsMay.29,2025

-

WIKA Diaphragm Seal Pressure Gauges Corrosion-Resistant & Durable

NewsMay.29,2025

-

Precision Differential Pressure Gauge Assembly Reliable & Customizable Solutions

NewsMay.29,2025

-

WIKA Sanitary Diaphragm Pressure Gauge High Precision & Durability

NewsMay.29,2025

-

HD Fire Pressure Gauges High Accuracy & Durable Solutions

NewsMay.28,2025