Nov . 08, 2024 02:06 Back to list

Precision Instruments Pressure Gauges for Accurate Measurement and Reliable Performance

Precision Instruments Pressure Gauge Ensuring Accurate Measurement in Various Applications

Pressure gauges are essential instruments in many industrial and scientific applications, offering reliable and precise measurements of pressure in various systems. Among the brands that have earned a reputation for quality and precision is Precision Instruments, known for its commitment to blending technology and craftsmanship to produce superior pressure gauges. In this article, we will explore the features, types, and applications of Precision Instruments pressure gauges, highlighting their importance in maintaining operational efficiency and safety.

Understanding Pressure Gauges

A pressure gauge is a device that measures the pressure of gases or liquids within a container or system. These instruments can provide readings in various units, including psi (pounds per square inch), bar, or Pascal. Pressure gauges are crucial in industries such as manufacturing, automotive, healthcare, and oil and gas, where maintaining specific pressure levels is vital for safety and performance.

The Precision Instruments Advantage

Precision Instruments specializes in manufacturing high-quality pressure gauges designed to meet rigorous industry standards. Their gauges are celebrated for their durability, accuracy, and ease of use. One of the key features that sets Precision Instruments apart is the meticulous calibration process they employ, ensuring that each gauge delivers accurate measurements within specified tolerances.

Precision Instruments pressure gauges are constructed from top-grade materials, making them suitable for a range of environments, including those with extreme temperatures or corrosive substances. This durability means that users can rely on them for long-term operation without the need for frequent replacements or recalibrations—saving time and money while enhancing efficiency.

Types of Pressure Gauges

Precision Instruments offers a wide variety of pressure gauges to meet diverse needs

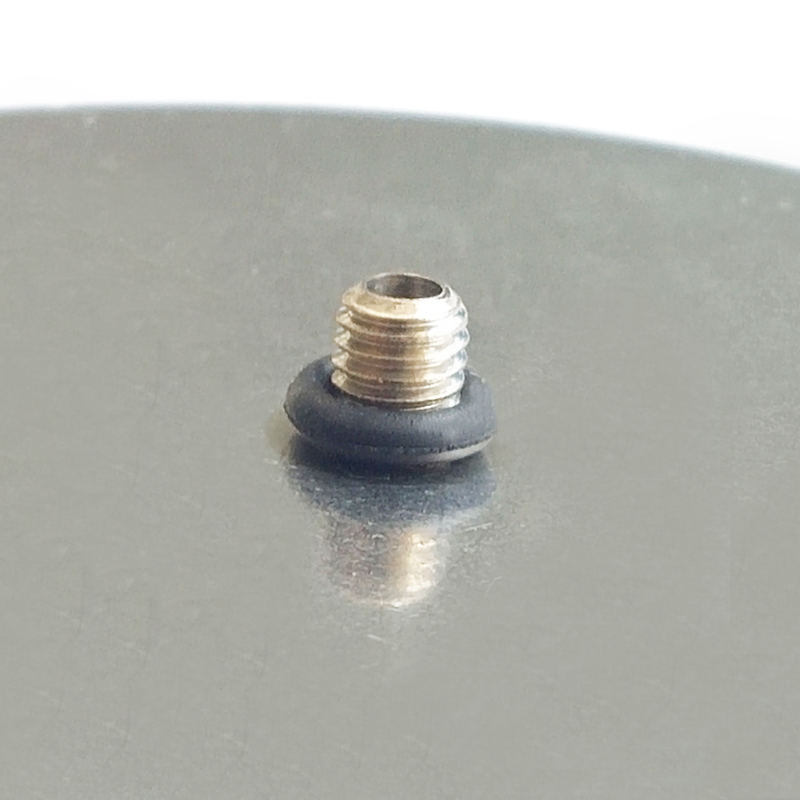

. Some of the common types includeprecision instruments pressure gauge product

1. Analog Pressure Gauges These traditional gauges feature a dial with a needle indicating the pressure reading. They are easy to read and do not require powered components, which makes them ideal for many basic applications.

2. Digital Pressure Gauges Equipped with electronic sensors, digital gauges provide precise readings that can be easily read on a digital display. They often include features such as data logging and alarm functions for enhanced utility.

3. Differential Pressure Gauges These gauges measure the difference in pressure between two points, making them crucial for applications where pressure differentials are significant, such as in filtration systems or heating and cooling systems.

4. Liquid-filled Pressure Gauges In these gauges, a liquid fills the casing to dampen vibrations and provide more stable readings, which is particularly beneficial in environments with high vibrations or pulsating pressures.

Applications of Precision Instruments Pressure Gauges

The versatility of Pressure Instruments pressure gauges makes them suitable for a myriad of applications. In the manufacturing industry, accurate pressure monitoring is critical in processes like extrusion, molding, and assembly lines. Similarly, in the automotive sector, these gauges are used to monitor tire pressure, hydraulic systems, and fuel lines to optimize performance and safety.

In healthcare, pressure gauges play a vital role in medical equipment, ensuring that devices such as ventilators and anesthesia machines operate within safe pressure levels. The oil and gas industry also relies heavily on pressure gauges to monitor equipment performance and ensure safe operational practices.

Conclusion

Precision Instruments pressure gauges exemplify the importance of accurate measurement in various industrial and scientific realms. With their commitment to high-quality manufacturing, innovative designs, and an extensive range of types, these gauges provide users with reliable solutions for pressure monitoring. As industries continue to prioritize efficiency, safety, and quality control, Precision Instruments will remain at the forefront, delivering instruments that meet the evolving needs of their customers. Whether you're in manufacturing, healthcare, or any other sector that requires precise pressure measurement, investing in Precision Instruments pressure gauges is a decision that guarantees accuracy and reliability.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025