Dec . 16, 2024 16:21 Back to list

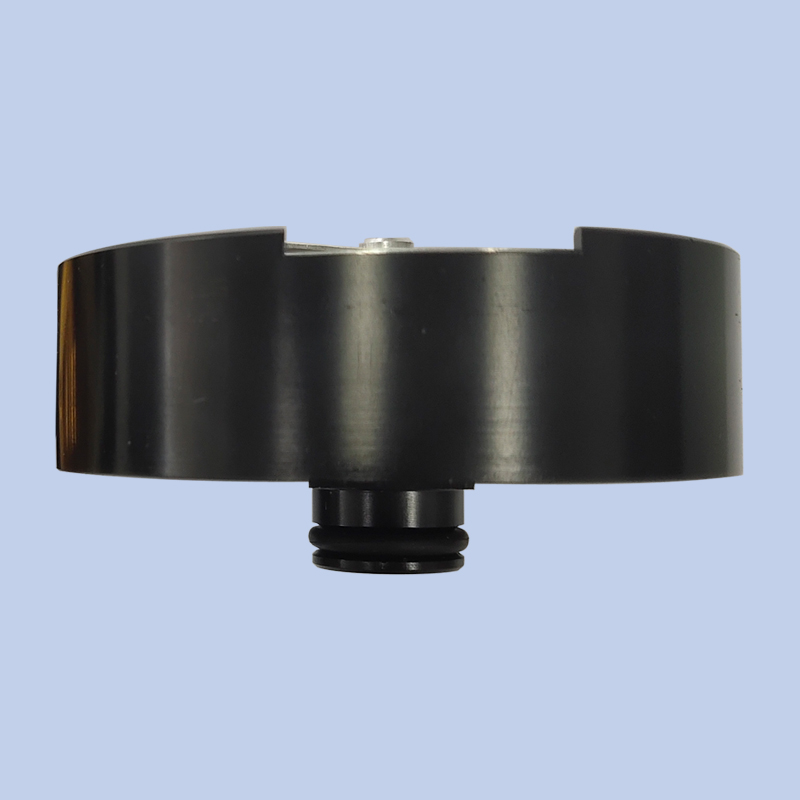

precision pressure gauges products

Precision Pressure Gauges Ensuring Accuracy in Measurement

In various industrial applications, the need for accurate and reliable pressure measurement cannot be overstated. Precision pressure gauges are critical instruments that ensure the integrity and efficiency of processes in sectors ranging from manufacturing to pharmaceuticals. These gauges are engineered to provide precise readings, which are essential for monitoring and controlling pressure levels in systems such as boilers, tanks, and pipelines.

One of the primary advantages of precision pressure gauges is their ability to deliver consistent and accurate measurements. Unlike standard gauges, which may exhibit variations due to environmental factors or manufacturing tolerances, precision gauges are designed with advanced techniques and materials that minimize error margins. These devices typically feature high-quality materials, such as stainless steel or brass, which enhance their durability and reliability, even in demanding conditions.

Precision Pressure Gauges Ensuring Accuracy in Measurement

Digital pressure gauges have gained popularity due to their ease of use and the clarity of their readings. They employ sensors that convert pressure measurements into a digital format, displayed on an LCD or LED screen. This feature not only enhances readability but also allows for advanced functionalities like data logging and remote monitoring, which are essential for modern industries looking to optimize their operations.

precision pressure gauges products

Calibration is a critical aspect of maintaining precision pressure gauges. Regular calibration ensures that the gauges provide accurate measurements over time, which is vital for compliance with industry standards and regulations. Many manufacturers recommend calibration at least once a year, depending on usage and environmental conditions. Skilled personnel should carry out the calibration process, utilizing standardized reference gauges to verify the accuracy of the precision gauges.

The applications for precision pressure gauges are vast and varied. In the oil and gas industry, for example, pressure gauges are essential for monitoring well pressure, ensuring safety, and optimizing extraction processes. In the pharmaceutical industry, precision gauges play a crucial role in maintaining sterile environments and ensuring that processes operate within specified pressure ranges to guarantee product quality.

Moreover, the automotive sector relies heavily on precision pressure gauges for testing and monitoring tire pressure and fluid systems. Precise tire pressure is vital for safety, fuel efficiency, and overall vehicle performance. In manufacturing, precision pressure gauges ensure hydraulic systems operate safely and efficiently, reducing downtime and maintaining productivity.

In conclusion, precision pressure gauges are indispensable tools in a wide range of industries, providing accurate and reliable pressure measurements critical for operational efficiency and safety. With advancements in technology, these gauges continue to evolve, offering enhanced features and greater reliability. As industries strive for improved precision and efficiency, the importance of precision pressure gauges will only continue to grow, ensuring that critical systems operate smoothly and safely. When selecting a pressure gauge, it's essential to consider factors such as the measurement range, accuracy requirements, and the specific application to ensure the right choice for optimal performance.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025