Jan . 09, 2025 11:59 Back to list

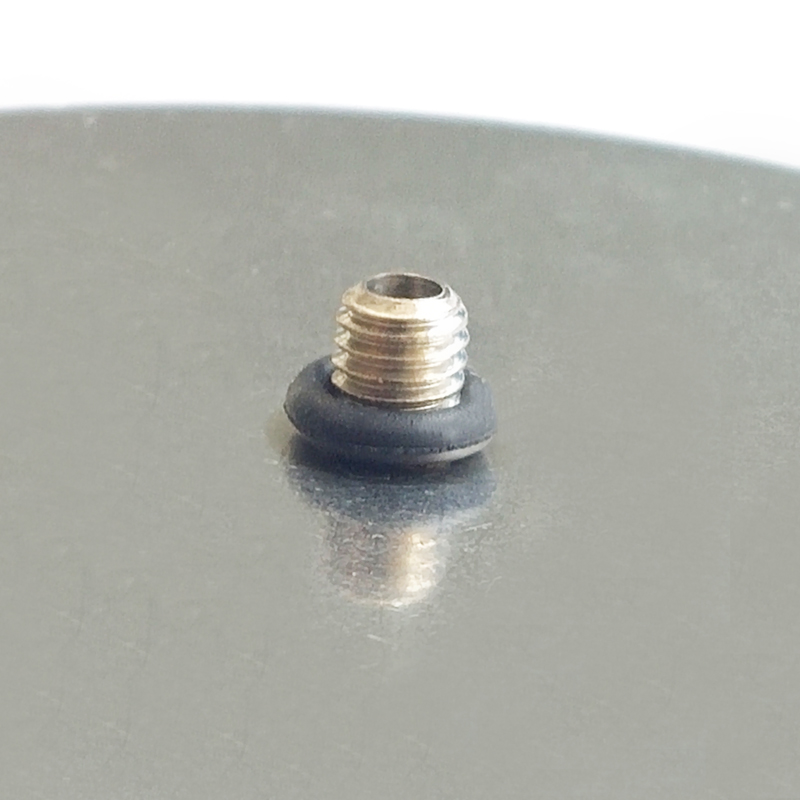

pressure diaphragm,

Navigating the complex world of industrial components, the pressure diaphragm stands out as a crucial element in various applications, including automotive, aerospace, and industrial automation. This thin, flexible membrane is tasked with the critical function of accurately measuring and translating pressure changes into an understandable output signal. However, understanding its full potential requires both experience and an in-depth appreciation of its intricate design and operational framework.

Authoritativeness in the field of pressure diaphragms is often derived from partnerships and feedback shared by industry leaders and engineers who have successfully implemented these components in challenging environments. For example, in the aerospace sector, where reliability and accuracy are non-negotiable, pressure diaphragms have been pivotal in achieving optimal flight performance by ensuring that systems respond accurately to real-time pressure changes. The trustworthiness of a pressure diaphragm is not just in its design and material but also in the track record of the manufacturer. Industry-recognized certifications and customer testimonials are important indicators of quality. Choosing a supplier with a proven history of delivering reliable products increases confidence that the diaphragm will perform as expected under specified conditions. Ultimately, the benefits of utilizing quality pressure diaphragms extend beyond mere functionality. They significantly enhance system efficiency, reduce maintenance costs, and improve safety. As such, they represent an indispensable investment for industries reliant on precise pressure measurement. Making informed choices fueled by experience, expert advice, and authoritative insights ensures that one leverages the full potential of this critical component, achieving both operational excellence and competitive advantage.

Authoritativeness in the field of pressure diaphragms is often derived from partnerships and feedback shared by industry leaders and engineers who have successfully implemented these components in challenging environments. For example, in the aerospace sector, where reliability and accuracy are non-negotiable, pressure diaphragms have been pivotal in achieving optimal flight performance by ensuring that systems respond accurately to real-time pressure changes. The trustworthiness of a pressure diaphragm is not just in its design and material but also in the track record of the manufacturer. Industry-recognized certifications and customer testimonials are important indicators of quality. Choosing a supplier with a proven history of delivering reliable products increases confidence that the diaphragm will perform as expected under specified conditions. Ultimately, the benefits of utilizing quality pressure diaphragms extend beyond mere functionality. They significantly enhance system efficiency, reduce maintenance costs, and improve safety. As such, they represent an indispensable investment for industries reliant on precise pressure measurement. Making informed choices fueled by experience, expert advice, and authoritative insights ensures that one leverages the full potential of this critical component, achieving both operational excellence and competitive advantage.

Share

Latest news

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025