Jan . 06, 2025 19:02 Back to list

pressure diaphragm capsule element,

The pressure diaphragm capsule element is a pivotal component in the measurement of pressure within various industrial applications. Crafted with precision and engineered for reliability, this element serves as the heart of pressure transducers and gauges. Understanding its functionalities and implications in the field unravels the sophisticated blend of science and engineering that powers modern industrial solutions.

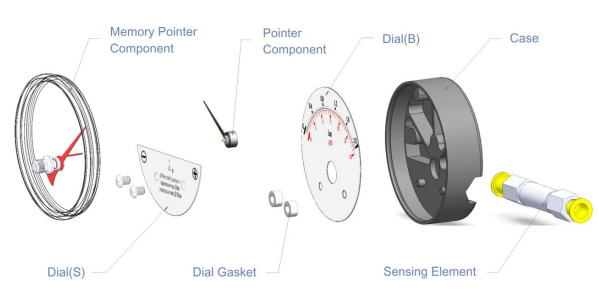

The unique design of the pressure diaphragm capsule element allows it to measure pressure with exceptional accuracy. Comprised of two flexible membranes or diaphragms, it works by converting pressure into displacement. This displacement is then converted into an electrical signal, allowing for precise measurement and monitoring. The materials used in these diaphragms are typically robust metals or high-grade elastomers, chosen for their ability to withstand immense pressure and varying temperatures without deforming.

Industries such as oil and gas, chemical manufacturing, and aerospace heavily rely on these elements for their day-to-day operations. In the oil and gas sector, for instance, monitoring pressure levels accurately is crucial to ensure safety and optimize extraction processes. The pressure diaphragm capsule element excels here due to its high sensitivity and ability to provide real-time data, ensuring any anomalies are quickly addressed.

In terms of expertise, engineering teams have come to rely on these elements for their outstanding durability and long service life. Rigorous testing is conducted to guarantee that each element can endure the harsh environments and stress it will face. This testing often involves exposing the element to extreme temperatures, corrosive substances, and high-pressure situations to ensure performance consistency and reliability.

pressure diaphragm capsule element,

Authoritative figures in the field vouch for the adaptability of the pressure diaphragm capsule element. It can be modified to suit a wide range of applications, from low-pressure scenarios to high-pressure environments, making it a versatile tool in the engineer's arsenal. Advances in technology have also led to the integration of smart features, where these elements are now capable of self-diagnosis and interfacing with digital systems for more integrated process control.

Trustworthiness in these elements is non-negotiable. Manufacturers of pressure diaphragm capsule elements adhere to strict international standards, such as the ASME and IEC guidelines, to ensure the safety and efficacy of their products. Furthermore, certified third-party testing and validation provide an extra layer of assurance that these elements will perform as expected under any given condition.

In conclusion, the pressure diaphragm capsule element is an indispensable component in the landscape of industrial measurement and control. Its design and functionality embody the principles of precision engineering, while its widespread application underscores its importance across various sectors. For those seeking accuracy, reliability, and sustainability in pressure measurement, the pressure diaphragm capsule element stands as a testament to engineering excellence.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025