Jan . 09, 2025 11:49 Back to list

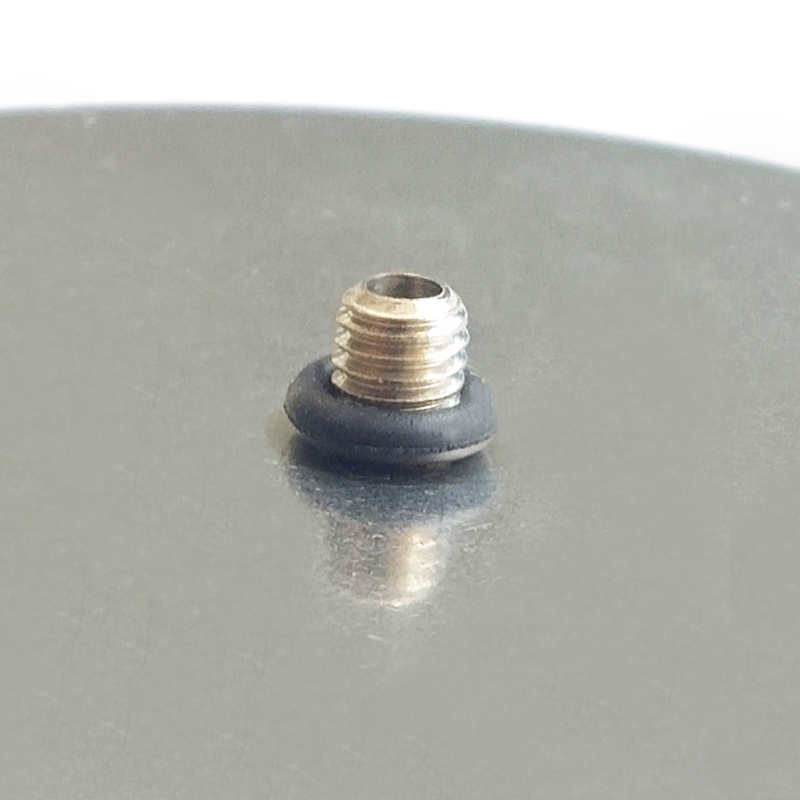

High purity pressure gauge(HPG,H- pressure) - VCR1/4" Female Face Seal Swivel / BA grade-10

Understanding the Intricacies of Pressure Diaphragm Capsule Elements A Comprehensive Guide

Years of field testing and engineering research have refined the designs of these elements. Experts in sensor technology understand that the key to a reliable pressure diaphragm capsule is a meticulously manufactured diaphragm. This diaphragm must be thin enough to respond accurately to minute pressure changes, yet robust enough to withstand the operating environment’s potential corrosive effects. Advanced manufacturing techniques, such as laser welding and electron beam welding, are employed to achieve these stringent requirements, ensuring the longevity and accuracy of the diaphragm capsule. The scientific rigor behind pressure diaphragm capsule elements positions them as authoritative solutions in pressure measurement. Institutions and regulatory bodies frequently test these devices, subjecting them to conditions that mimic real-world applications to verify their performance standards. Published research often highlights the evolution of designs that have minimized hysteresis and maximized temperature compensation, ensuring pressure diaphragm capsules remain at the forefront of measurement solutions. Choosing the right supplier for pressure diaphragm capsule elements is a decision that should not be taken lightly. Trustworthiness in a supplier can be established through certifications, adherence to international standards such as ISO 9001, and a proven track record in the industry. Clients are advised to seek suppliers that offer comprehensive support, from the initial consultation stage to after-sales service. Customized solutions, where the diaphragm capsules are tailored to specific measurement environments, further attest to a supplier's commitment to excellence and customer satisfaction. In conclusion, pressure diaphragm capsule elements are indispensable in delivering exact pressure measurements across various sectors. The experience derived from their application in challenging environments underscores their necessity. The expertise poured into their design and development speaks to their efficiency and precision. Their establishment as authoritative instruments owes to the relentless pursuit of perfection by engineers and manufacturers. Finally, the trust they command is a testament to the enduring partnerships they form with industries reliant on dependable pressure measurement.

Years of field testing and engineering research have refined the designs of these elements. Experts in sensor technology understand that the key to a reliable pressure diaphragm capsule is a meticulously manufactured diaphragm. This diaphragm must be thin enough to respond accurately to minute pressure changes, yet robust enough to withstand the operating environment’s potential corrosive effects. Advanced manufacturing techniques, such as laser welding and electron beam welding, are employed to achieve these stringent requirements, ensuring the longevity and accuracy of the diaphragm capsule. The scientific rigor behind pressure diaphragm capsule elements positions them as authoritative solutions in pressure measurement. Institutions and regulatory bodies frequently test these devices, subjecting them to conditions that mimic real-world applications to verify their performance standards. Published research often highlights the evolution of designs that have minimized hysteresis and maximized temperature compensation, ensuring pressure diaphragm capsules remain at the forefront of measurement solutions. Choosing the right supplier for pressure diaphragm capsule elements is a decision that should not be taken lightly. Trustworthiness in a supplier can be established through certifications, adherence to international standards such as ISO 9001, and a proven track record in the industry. Clients are advised to seek suppliers that offer comprehensive support, from the initial consultation stage to after-sales service. Customized solutions, where the diaphragm capsules are tailored to specific measurement environments, further attest to a supplier's commitment to excellence and customer satisfaction. In conclusion, pressure diaphragm capsule elements are indispensable in delivering exact pressure measurements across various sectors. The experience derived from their application in challenging environments underscores their necessity. The expertise poured into their design and development speaks to their efficiency and precision. Their establishment as authoritative instruments owes to the relentless pursuit of perfection by engineers and manufacturers. Finally, the trust they command is a testament to the enduring partnerships they form with industries reliant on dependable pressure measurement.

Share

Latest news

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025