Nov . 19, 2024 03:01 Back to list

Innovative Diaphragm Designs for Advanced Pressure Sensing Technologies in Modern Applications

Understanding Pressure Sensing Elements The Role of Diaphragms

Pressure sensing elements are crucial components in a variety of industrial applications, from automotive systems to medical devices. At the heart of many of these sensors lies the diaphragm—a thin, flexible membrane that plays a significant role in converting pressure changes into measurable electrical signals. This article delves into the function of diaphragms in pressure sensors, exploring their design, materials, and application challenges.

The Function of Diaphragms in Pressure Sensors

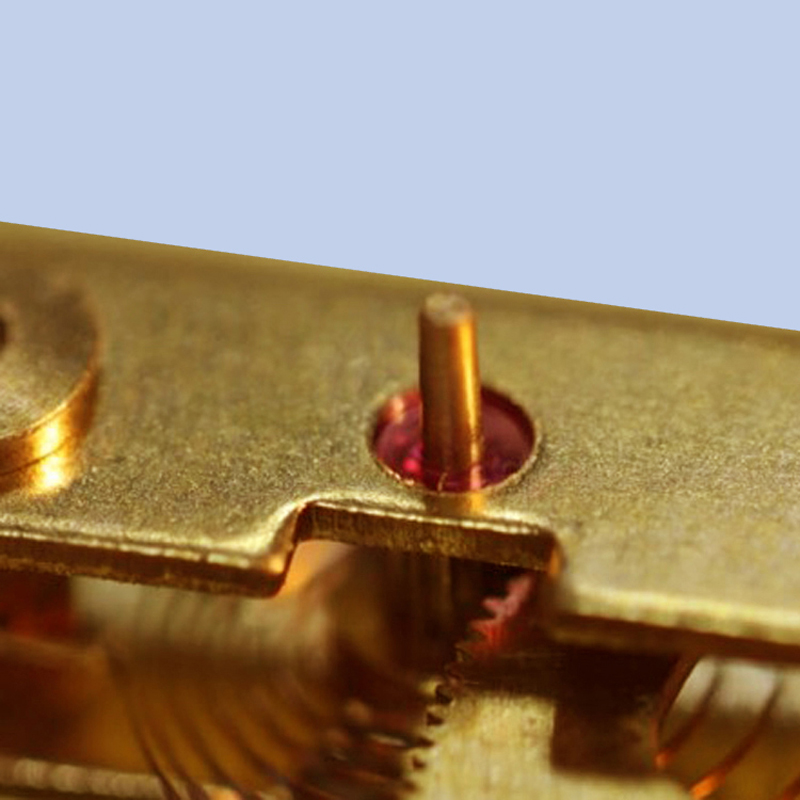

A diaphragm serves as the sensing element that responds to changes in pressure. When a pressure is applied to one side of the diaphragm, it deflects, causing a change in shape. This mechanical deformation can then be transformed into an electrical signal. The electrical output may occur through various mechanisms, including resistive, capacitive, or inductive methods, depending on the specific design of the sensor.

In capacitive pressure sensors, for example, the diaphragm acts as one plate of a capacitor. As the diaphragm deflects under pressure, the distance between the plates changes, altering the capacitance and thus generating an electrical signal proportional to the applied pressure. Similarly, in piezoresistive sensors, the diaphragm's deformation changes the resistance of a material embedded within it, resulting in a measurable output.

Material Considerations

The performance of a pressure sensor is heavily influenced by the materials used to construct the diaphragm. Common materials include stainless steel, silicone, and ceramic, each offering distinct advantages and limitations. Stainless steel is often favored for its durability and resistance to corrosion, making it ideal for high-pressure applications in harsh environments. On the other hand, silicone diaphragms are known for their flexibility and ability to be fabricated into complex shapes, which can enhance sensitivity.

Ceramic materials provide excellent chemical resistance and stability over a wide temperature range. However, they may be more brittle and less forgiving in dynamic pressure applications. Selection of the diaphragm material depends not only on the operational pressure range but also on the environmental conditions and the specific sensitivity requirements of the application.

pressure sensing elements diaphragm quotes

Design Challenges

Designing effective pressure sensing diaphragms comes with its share of challenges. One critical factor is ensuring that the diaphragm’s response is linear across its operating range. Non-linear responses can lead to inaccuracies in pressure measurement, which can significantly impact sensitive applications such as clinical diagnostics or aerospace technologies.

Furthermore, the thickness of the diaphragm must be carefully selected. Thicker diaphragms may be more durable and resistant to rupture but can show reduced sensitivity to small pressure changes. Conversely, thinner diaphragms may enhance sensitivity but can be prone to mechanical failure under high-pressure conditions. Balancing these conflicting requirements is key to developing a reliable pressure sensor.

Applications of Pressure Sensing Diaphragms

Diaphragms are used in a wide array of applications. In the automotive industry, they play a vital role in monitoring tire pressure, ensuring vehicle safety and performance. In medical devices, they are essential components of monitoring systems for blood pressure, breathing levels, and other vital signs. Industrial applications often require the precise control of fluids and gases, where diaphragm-based sensors provide accurate measurements critical for process optimization.

Moreover, advancements in technology are allowing for the miniaturization of pressure sensors with diaphragms that fit in compact devices. This development is particularly noticeable in wearable technology, where space is at a premium, yet accurate pressure readings are still paramount for functionality.

Conclusion

In summary, pressure sensing diaphragms are indispensable elements in the world of pressure measurement. Their ability to convert mechanical pressure into measurable electrical signals makes them crucial for a wide range of applications across various industries. By carefully selecting materials and designing the diaphragm to meet specific requirements, engineers can overcome the challenges associated with pressure sensing technology. As technology continues to advance, the evolution of pressure sensing elements, including their diaphragms, promises even greater accuracy, reliability, and application diversity in the future.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025