Oct . 03, 2024 05:04 Back to list

Remote Diaphragm Seal Pressure Measurement Solutions for Accurate Industrial Applications

Understanding Remote Diaphragm Seal Pressure Gauges A Company Perspective

In the world of industrial measurement and control, the importance of accurate pressure readings cannot be overstated. Remote diaphragm seal pressure gauges have emerged as essential tools for various industries, providing reliable measurements in challenging conditions. This article explores the significance of these instruments and highlights the role of companies specializing in their production and distribution.

What Are Remote Diaphragm Seal Pressure Gauges?

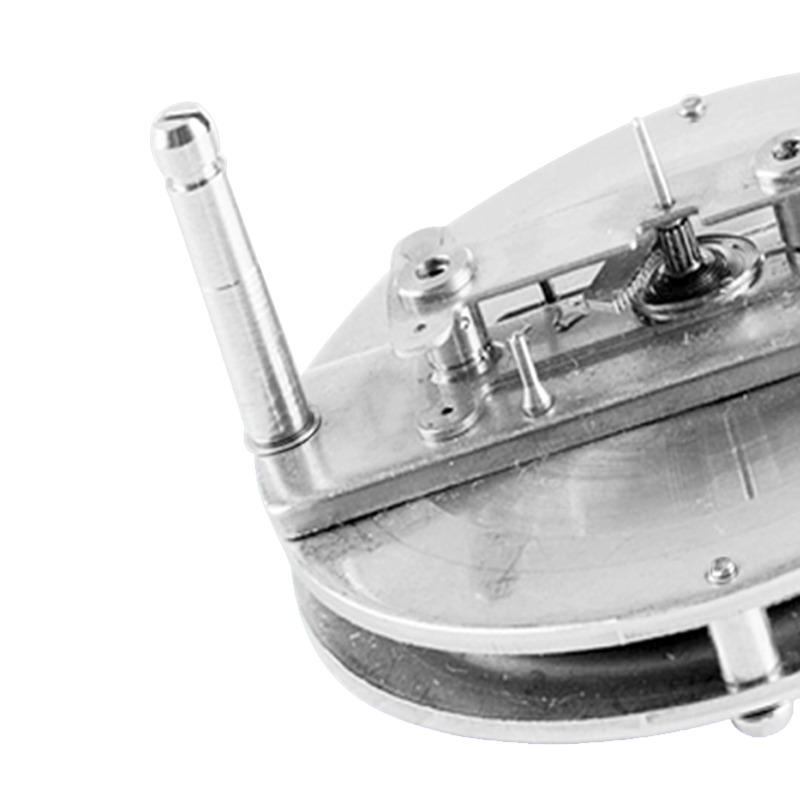

Remote diaphragm seal pressure gauges are specialized devices designed to measure pressure in fluids and gases, especially when direct contact with the process media is not feasible or safe. These gauges use a diaphragm—a thin, flexible membrane—to transmit pressure readings from the process medium to the measuring instrument located at a distance. This design is particularly advantageous in applications involving corrosive, viscous, or high-temperature substances.

Key Advantages of Remote Diaphragm Seal Pressure Gauges

1. Enhanced Protection Against Corrosion One of the primary benefits of using remote diaphragm seals is their ability to protect the gauge from corrosive materials. The diaphragm serves as a barrier, preventing the process media from directly contacting the pressure sensing element. This significantly extends the life of the gauge and decreases maintenance costs.

2. Increased Measurement Accuracy These gauges minimize the risk of blockage and ensure accurate pressure readings over time. Since the diaphragm can accommodate changes in pressure without being affected by the properties of the process fluid, users can count on consistent and reliable measurements.

3. Versatility Remote diaphragm seal pressure gauges are suitable for various applications, including chemical processing, food and beverage production, pharmaceuticals, and oil and gas industries. Their ability to handle different fluids and environmental conditions makes them indispensable in many settings.

4. Safety In hazardous environments, ensuring safety is paramount. Remote diaphragm seal gauges can be mounted away from the process, allowing for safer operation in environments that may pose risks to personnel. Furthermore, they can be designed to withstand extreme temperatures and pressures.

remote diaphragm seal pressure gauge company

The Role of Companies in Providing Solutions

Companies that specialize in the manufacturing and distribution of remote diaphragm seal pressure gauges play a crucial role in various industries. They are responsible for

- Research and Development Investing in R&D to innovate and improve the design and functionality of pressure gauges. Advances in materials and technology can lead to more robust, accurate, and reliable instruments.

- Customization Offering tailored solutions to meet specific industry requirements. This includes designing custom diaphragm materials and shapes that are best suited for particular media or environmental conditions.

- Technical Support and Service Providing expert guidance to customers regarding the selection, installation, and maintenance of pressure gauges. This support ensures that users can effectively integrate these instruments into their operations.

- Quality Assurance Ensuring that their products meet industry standards and regulations. Reliable quality assurance processes lead to increased trust among customers and a solid reputation in the market.

Conclusion

The significance of remote diaphragm seal pressure gauges cannot be understated in today’s industrial landscape. Companies specializing in these instruments are vital in advancing technology, ensuring safety, and providing precise measurements across various applications. As industries continue to evolve, the demand for innovative pressure measurement solutions will only grow, highlighting the critical role of these companies in an increasingly complex world.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025