Nov . 05, 2024 12:18 Back to list

remote diaphragm seal pressure gauge products

Understanding Remote Diaphragm Seal Pressure Gauge Products

In industrial applications where pressure measurement is crucial, the remote diaphragm seal pressure gauge stands out as a reliable and efficient solution. This device is particularly beneficial in scenarios where harsh or corrosive conditions might compromise the accuracy and lifespan of traditional pressure gauges. By separating the measuring element from the process fluid, remote diaphragm seals ensure accurate readings even in challenging environments.

What is a Remote Diaphragm Seal Pressure Gauge?

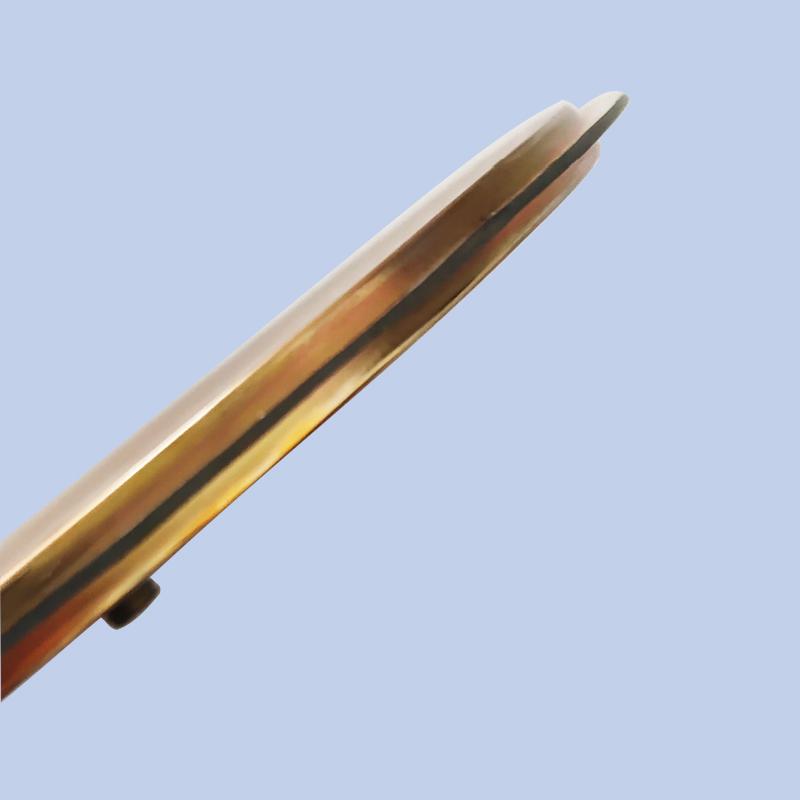

A remote diaphragm seal pressure gauge consists of a diaphragm seal, a pressure gauge, and a capillary tube that connects the two. The diaphragm, typically made from materials resistant to chemical erosion, acts as a barrier between the process fluid and the gauge itself. When the pressure of the fluid acts on the diaphragm, it transmits this force through the capillary tube to the pressure gauge, where the pressure reading is displayed. This design not only protects the gauge but also allows measurement in extreme conditions, including high temperatures, high pressures, or corrosive substances.

Key Advantages

1. Protection from Harsh Environments The primary advantage of diaphragm seals is their ability to protect the pressure gauge from damage. This is essential in processes involving caustic chemicals, viscous fluids, or high-temperature environments, where direct contact could lead to corrosion or clogging.

2. Accuracy and Reliability By isolating the pressure measurement from the process fluid, remote diaphragm seals provide more accurate and consistent pressure readings. This is crucial in applications where precise measurements are vital, such as in chemical processing, oil and gas production, and food processing.

3. Versatility These products can be customized to fit various applications. The materials used for diaphragms can be selected based on the type of fluid being measured, temperature, and pressure requirements, thus making them adaptable to a wide range of industries.

remote diaphragm seal pressure gauge products

4. Reduced Maintenance Since the diaphragm seal protects the gauge, it results in lower maintenance needs. The longevity of the pressure gauge is enhanced because it is shielded from the damaging effects of the media, reducing downtime and maintenance costs.

5. Safety In high-pressure applications, a failure in a pressure gauge could lead to dangerous situations. Remote diaphragm seal pressure gauges help mitigate this risk by ensuring that the sensitive components of the measurement system are safely distanced from the process.

Applications

Remote diaphragm seal pressure gauges find extensive use in various industries including

- Chemical Processing For safe measurement of corrosive substances. - Oil and Gas To monitor pressures in wells and pipelines. - Food Industry Ensuring hygiene and preventing contamination during pressure measurement. - Pharmaceuticals Accurate pressure readings in clean and controlled environments.

Conclusion

The remote diaphragm seal pressure gauge is an indispensable tool in modern industrial applications. By enhancing accuracy, reliability, and safety, while also reducing maintenance needs, these gauges play a vital role in ensuring efficient and safe operations in numerous sectors. As industries continue to evolve and face more demanding environments, the importance of reliable pressure measurement solutions like remote diaphragm seals will only increase.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025