Oct . 03, 2024 07:30 Back to list

Sanitary Differential Pressure Gauge for Accurate Measurement in Hygienic Applications

Understanding Sanitary Differential Pressure Gauges

In various industries, particularly those that deal with fluid processing, maintaining a safe and efficient operation is crucial. One of the essential instruments used in such environments is the sanitary differential pressure gauge. This device is not just a simple measurement tool; it plays a critical role in ensuring product quality, process efficiency, and system safety.

What is a Sanitary Differential Pressure Gauge?

A sanitary differential pressure gauge is designed specifically for applications that require adherence to strict hygiene standards, such as in food processing, pharmaceuticals, and biotechnological industries. This gauge measures the pressure difference between two points in a system, which is often vital in processes like filtration, flow measurement, and tank level monitoring.

The “sanitary” aspect refers to the materials and design of the gauge, which typically includes stainless steel construction and sanitary fittings. These materials are non-porous, easy to clean, and resistant to corrosion, ensuring that they can withstand the rigors of high-pressure environments and are safe for applications involving sensitive products.

Importance of Differential Pressure Measurement

Understanding differential pressure is vital for several reasons. In filtration applications, for instance, a noticeable increase in differential pressure can indicate that a filter is becoming clogged. Monitoring this pressure can inform operators when it's time to replace or clean a filter, thus preventing process disruptions and potential contaminants from entering the product stream.

In addition to filtration, differential pressure measurements are crucial for maintaining optimal flow rates within piping systems. Variations in pressure can signal blockages or leaks, enabling timely maintenance actions that protect equipment and enhance system reliability.

Features of Sanitary Differential Pressure Gauges

Sanitary differential pressure gauges come with various features tailored for specific applications. Key attributes include

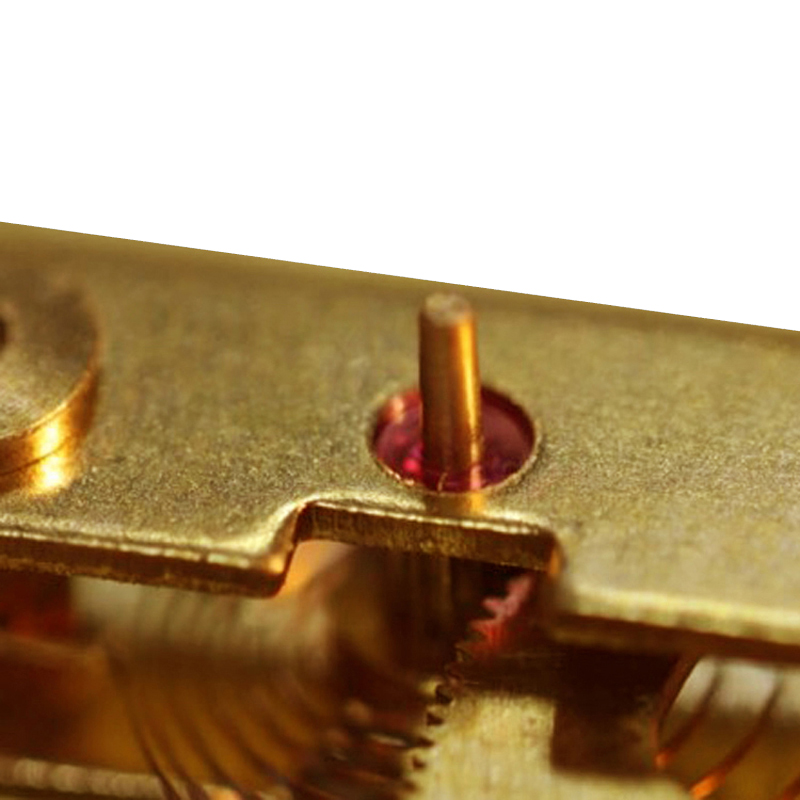

sanitary differential pressure gauge product

1. Sanitary Design With a focus on hygiene, these gauges are designed with smooth surfaces and minimal crevices to reduce the risk of contamination.

2. Accuracy and Sensitivity High accuracy is essential in many applications. These gauges are designed to provide precise measurements, often with high-resolution displays for easy readability.

3. Wide Temperature and Pressure Range They are engineered to operate under extreme temperatures and pressures, making them suitable for diverse industrial processes.

4. Easy Installation and Maintenance Many models are created for straightforward installation with standard sanitary fittings, facilitating regular maintenance and cleaning protocols.

5. Digital Options Some modern versions feature digital displays and remote monitoring capabilities, allowing for real-time data tracking and integration into a facility's control systems.

Applications

These gauges are widely used in various applications

- Filtration Systems Monitoring the condition of filters in liquid and gas applications to ensure efficiency and prevent contamination. - Tanks and Vessels Measuring the differential pressure between a tank and its atmosphere, providing insights into liquid levels and ensuring safe operations. - Process Control In pharmaceutical manufacturing, precise pressure control is vital for maintaining consistent product quality and compliance with regulatory standards.

Conclusion

In summary, sanitary differential pressure gauges are indispensable tools in industries requiring meticulous hygiene and safety standards. By effectively measuring differential pressure, these gauges help maintain optimal operational conditions, improve product quality, and ensure compliance with health regulations. Investing in high-quality sanitary differential pressure gauges is essential for any facility aiming to achieve operational excellence and safeguard consumer health. Whether you are involved in food processing, pharmaceuticals, or similar sectors, understanding and utilizing these gauges will be paramount to your success.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025