Jan . 14, 2025 12:29 Back to list

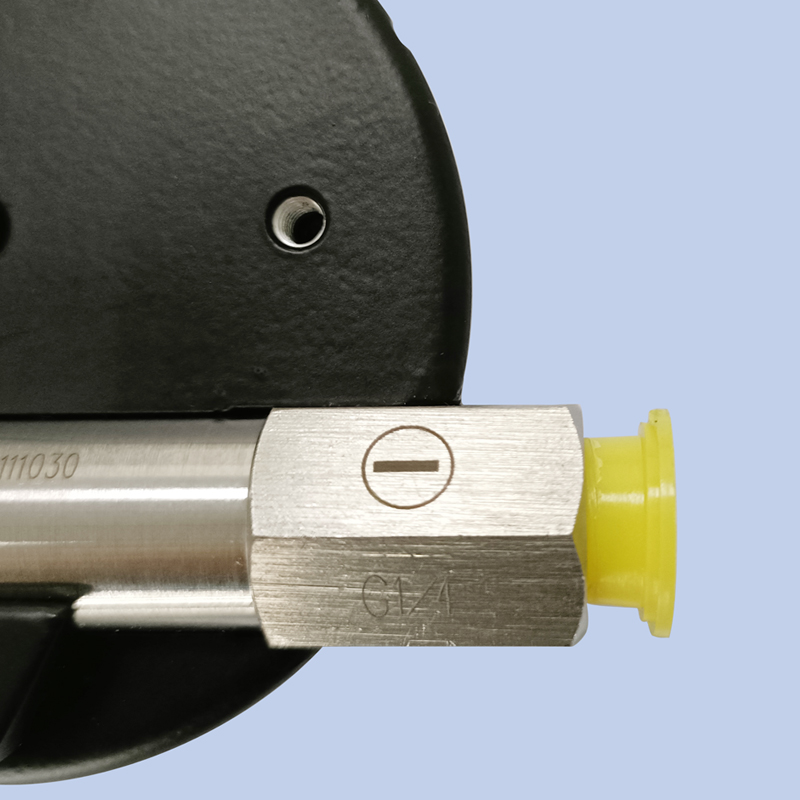

sealed diaphragm pressure gauge

The advancement of technology in industrial instrumentation has marked a significant progression in the accuracy and reliability of pressure measurement devices, among which sealed diaphragm pressure gauges stand out prominently. Over decades of utilization in various sectors, these devices have proven indispensable for industries prioritizing safety, precision, and longevity.

Authoritativeness in the field of sealed diaphragm pressure gauges is underpinned by adherence to industry standards and certifications. Reputable manufacturers who follow ISO, ASME, and API standards in their production processes establish a framework of trust and reliability. Their commitment to quality and performance is reflected in the thorough testing and inspection of each gauge, ensuring it meets rigorous industrial demands. Trustworthiness is further enhanced by real-world testimonials and case studies showcasing successful applications of sealed diaphragm gauges. Industries ranging from petrochemical to food and beverage cite these devices as critical components of their instrumentation strategies. The positive feedback from these applications not only reinforces the credibility of the product but also serves as a beacon for potential new users navigating the complexities of gauge selection. In conclusion, sealed diaphragm pressure gauges represent a sophisticated solution catering to the precise needs of industries facing challenging media interactions. Their design integrity, coupled with the ability to maintain consistent performance under duress, underscores their value as a critical component in industrial measurement systems. By aligning experience, expertise, authoritativeness, and trustworthiness, these gauges continue to set the standard in pressure measurement, offering peace of mind to operators worldwide. As industries evolve, the role of sealed diaphragm pressure gauges remains pivotal, adapting to the changing landscape while upholding safety and efficiency.

Authoritativeness in the field of sealed diaphragm pressure gauges is underpinned by adherence to industry standards and certifications. Reputable manufacturers who follow ISO, ASME, and API standards in their production processes establish a framework of trust and reliability. Their commitment to quality and performance is reflected in the thorough testing and inspection of each gauge, ensuring it meets rigorous industrial demands. Trustworthiness is further enhanced by real-world testimonials and case studies showcasing successful applications of sealed diaphragm gauges. Industries ranging from petrochemical to food and beverage cite these devices as critical components of their instrumentation strategies. The positive feedback from these applications not only reinforces the credibility of the product but also serves as a beacon for potential new users navigating the complexities of gauge selection. In conclusion, sealed diaphragm pressure gauges represent a sophisticated solution catering to the precise needs of industries facing challenging media interactions. Their design integrity, coupled with the ability to maintain consistent performance under duress, underscores their value as a critical component in industrial measurement systems. By aligning experience, expertise, authoritativeness, and trustworthiness, these gauges continue to set the standard in pressure measurement, offering peace of mind to operators worldwide. As industries evolve, the role of sealed diaphragm pressure gauges remains pivotal, adapting to the changing landscape while upholding safety and efficiency.

Share

Latest news

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025