Oct . 16, 2024 08:21 Back to list

Innovative Solid Front Differential Pressure Gauge for Enhanced Performance and Accuracy

Understanding Solid Front Differential Pressure Gauges

Differential pressure gauges are indispensable tools utilized across various industries to measure the difference in pressure between two points. Among the different types of differential pressure gauges, solid front differential pressure gauges are particularly notable for their robustness and reliability. This article delves into the features, applications, advantages, and operational principles of solid front differential pressure gauges.

What is a Solid Front Differential Pressure Gauge?

A solid front differential pressure gauge features a unique design where the front of the gauge is reinforced, which helps protect the internal components from damage and enhances user safety. These gauges are primarily used to monitor the pressure of gases and liquids in applications where safety and precision are paramount.

Key Features

1. Safety Design The solid front design minimizes the risk of breakage in high-pressure environments. This is especially beneficial in hazardous settings where exposure to chemicals or high-pressure fluids can pose significant risks.

2. Durability Solid front gauges are constructed from durable materials that allow them to withstand harsh operating conditions. They are often made of stainless steel or other robust materials that resist corrosion.

3. Accuracy These gauges provide precise readings, which are essential for maintaining optimal operating conditions in various systems.

4. Easy Maintenance Many solid front differential pressure gauges are designed for easy calibration and maintenance. This ensures that they can continue to provide accurate readings over time without excessive downtime.

Applications

Solid front differential pressure gauges are widely used across several industries, including

- Oil and Gas In exploration and production, monitoring pressure differences is crucial for ensuring the integrity of pipelines and preventing leaks

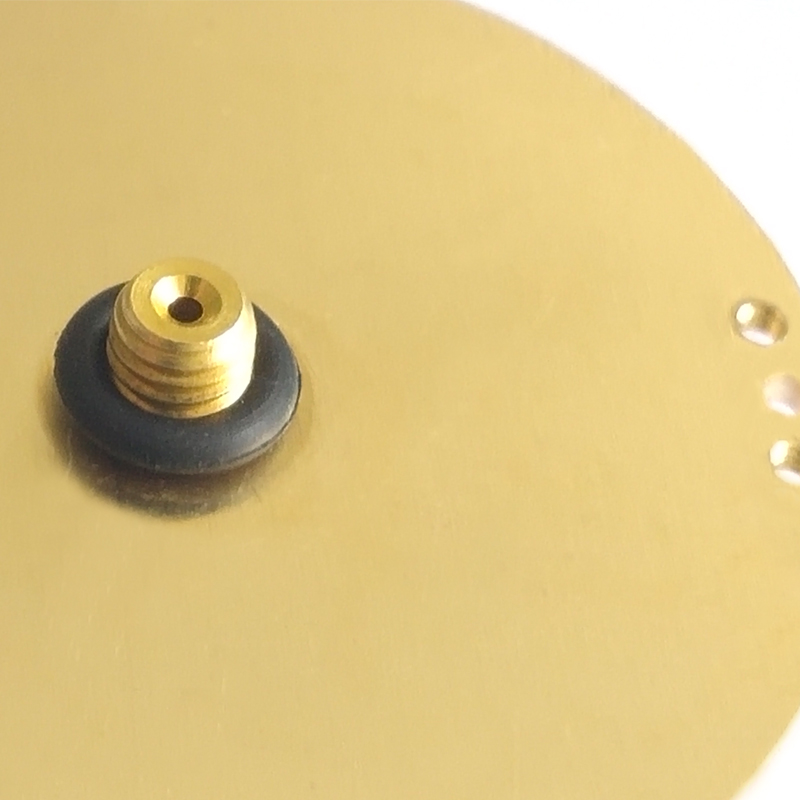

. - Chemical Processing These gauges help maintain proper chemical flows and monitor system pressures to ensure safety and efficiency.solid front differential pressure gauge product

- HVAC Systems In heating, ventilation, and air conditioning, solid front gauges monitor air pressure differentials across filters and ducts to optimize airflow and energy efficiency.

- Water Treatment They are used to monitor pressures in filtration systems and ensure optimal water quality.

- Pharmaceuticals Accurate monitoring of pressure is vital in processes where contamination could compromise product quality.

Advantages

The use of solid front differential pressure gauges offers several advantages

1. Enhanced Safety With a solid front design, the risk of release of hazardous materials due to breakage is significantly reduced, making these gauges safer in critical applications.

2. Precision Measurement The accuracy of these gauges makes them ideal for applications where maintaining specific pressure differentials is essential.

3. Versatile Design They can be used for various liquids and gases, making them adaptable for numerous industrial applications.

4. Reduced Downtime Since many solid front gauges are easy to maintain and calibrate, they help minimize operational downtime, ensuring continuous monitoring and operation.

Conclusion

Solid front differential pressure gauges are vital instruments in ensuring the safety and efficiency of various industrial processes. Their robust design, precision, and adaptability make them preferred choices for challenging environments where accurate pressure monitoring is crucial. As industries continue to evolve and prioritize safety and efficiency, the importance of reliable measurement tools like solid front differential pressure gauges will only increase, underscoring their critical role in modern industrial applications.

Understanding the features and applications of these gauges can help businesses select the right tools for their specific needs, ensuring optimal operation and safety in their processes. Whether in chemical processing, HVAC, or water treatment, investing in high-quality solid front differential pressure gauges is a decision that pays dividends in safety and reliability.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025