Nov . 06, 2024 18:23 Back to list

Differential Pressure Gauge Solutions for Enhanced Measurement Accuracy and Performance

Understanding Square Root Differential Pressure Gauge Technology

In various industrial applications, measuring pressure accurately is critical for ensuring safety, efficiency, and optimal performance. One of the pivotal instruments used for this purpose is the square root differential pressure gauge. This technology is particularly essential in applications involving flow measurement in water and wastewater treatment, oil and gas, and various chemical processes.

What is a Square Root Differential Pressure Gauge?

A square root differential pressure gauge is a specific type of pressure measurement device that determines the flow rate of a fluid by measuring the differential pressure across an orifice, venturi, or other flow restriction. The fundamental basis of this measuring technique lies in the principle that the flow rate is proportional to the square root of the differential pressure. Hence, the name square root differential pressure gauge.

When fluid flows through a pipe with a constriction, the pressure decreases as the fluid speed increases. The differential pressure gauge captures this difference and computes the flow rate by taking the square root of the measured pressure differential. This correlation allows for accurate and efficient flow measurement, making it integral to numerous industrial processes.

How Does It Work?

To understand the operation of a square root differential pressure gauge, it's essential to grasp its components and operating principles. The primary components include

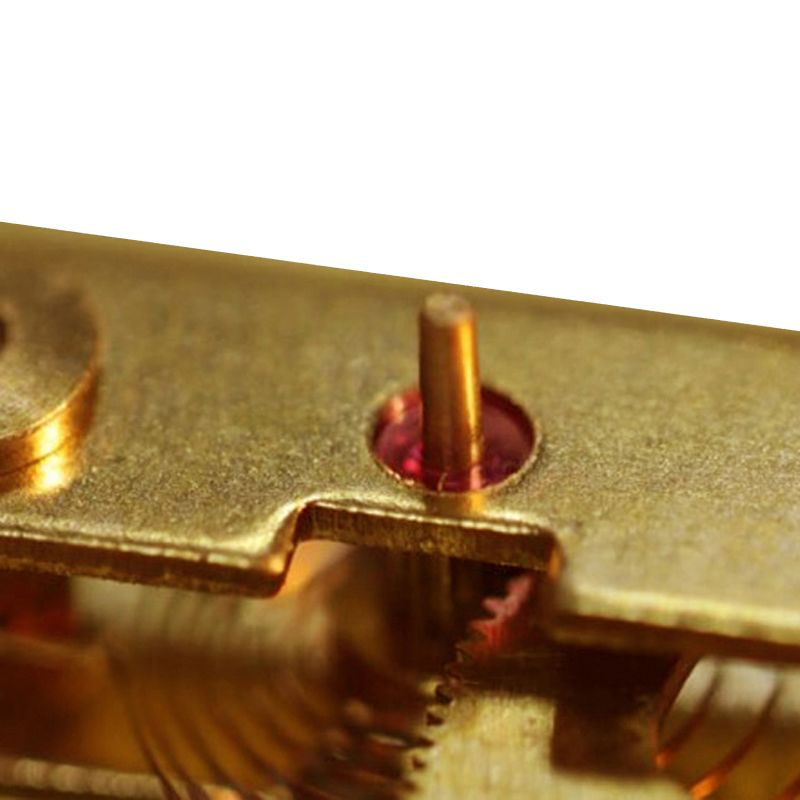

1. Pressure Sensing Elements These are typically high-precision pressure transducers or diaphragm-based sensors that measure the pressure at two points – upstream (high-pressure) and downstream (low-pressure) of the flow restriction.

2. Differential Pressure Transmitter This device processes the signals from the pressure sensors and calculates the differential pressure.

4. Display and Output Interfaces The processed data is then presented through gauges, digital displays, or transmitted digitally to control systems or data logging devices.

The accuracy and reliability of this system have made it a standard choice for flow measurement across various sectors.

square root differential pressure gauge company

Applications

Square root differential pressure gauges find applications in several industries, including

- Water and Wastewater Treatment These gauges are widely used for measuring flow in treatment plants, ensuring optimal operation and efficient management of resources.

- Oil and Gas In upstream and downstream processes, these gauges play a crucial role in flow measurement and sumping in pipelines, ensuring regulatory compliance and safety.

- Chemical Processing In chemical plants, precise flow measurements are vital for maintaining process integrity and ensuring product quality.

Advantages

1. Accuracy The inherent design of square root differential pressure gauges allows for high accuracy in flow measurements, with minimal errors.

2. Versatility These gauges can easily adapt to various measurement scenarios involving different fluids, from gases to viscous liquids.

3. Reduced Maintenance With fewer moving parts compared to other flow measurement technologies, square root differential pressure gauges generally require less maintenance, reducing operational downtime.

4. High Dynamic Range They can operate effectively over a broad range of flow conditions, making them suitable for varying process requirements.

Conclusion

The square root differential pressure gauge is an exemplary tool in the field of pressure measurement. Its ability to provide accurate and reliable flow measurements makes it indispensable across various industries. Understanding this technology helps organizations optimize their processes, enhance safety, and ensure compliance with industry standards. As industries continue to evolve, the demand for precision measurement techniques like square root differential pressure gauges will only grow, affirming their place at the forefront of technological advancement in industrial applications.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025