Dec . 06, 2024 19:42 Back to list

stainless steel differential pressure gauge factories

The Significance of Stainless Steel Differential Pressure Gauges in Industrial Applications

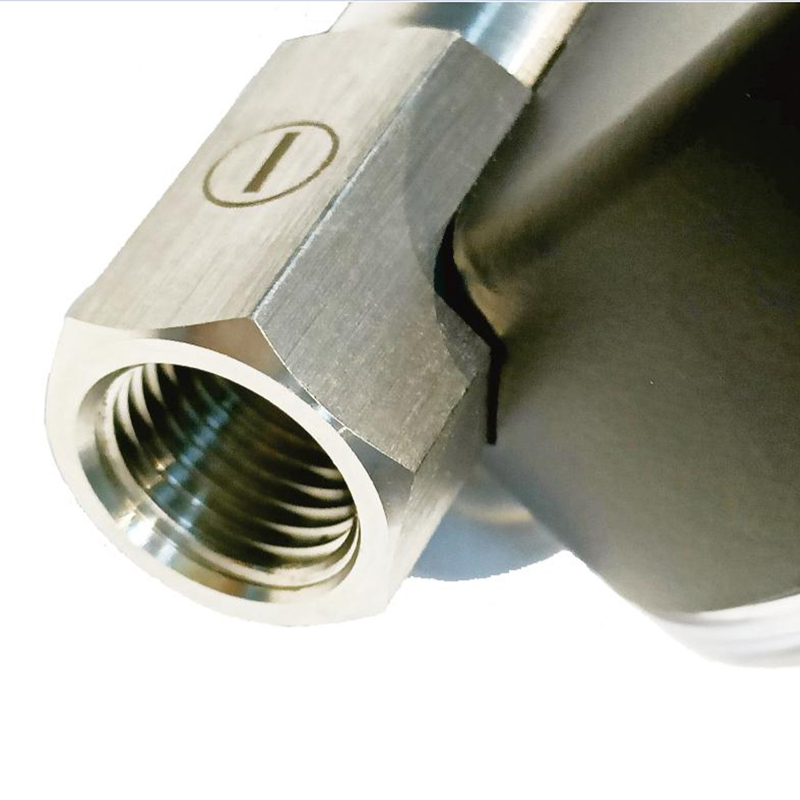

In various industrial applications, the ability to accurately measure pressure differences is crucial for maintaining optimal operational efficiency and safety. One of the most reliable tools for this purpose is the stainless steel differential pressure gauge. This instrument provides critical insights into the performance of processes involving gases, liquids, and slurries, thus playing a vital role in numerous sectors, including chemical processing, water treatment, HVAC systems, and oil and gas.

Understanding Differential Pressure Gauges

Differential pressure gauges measure the difference in pressure between two points in a system. The significance of this measurement lies in its ability to indicate flow rates, filter conditions, and the overall health of various components within a process. For instance, in filtration systems, a rise in differential pressure often signals that a filter is becoming clogged and may need maintenance or replacement. This allows operators to prevent system failures and maintain product quality.

The Role of Stainless Steel

Stainless steel is the material of choice for many differential pressure gauges, offering several beneficial properties. The most notable advantages of stainless steel include its resistance to corrosion, durability, and strength. These properties are particularly important in industries where harsh environmental conditions and exposure to corrosive substances are common. For example, in the chemical processing industry, equipment and instruments are often subjected to acids, bases, and other corrosive agents. A stainless steel differential pressure gauge can withstand such conditions without deteriorating, ensuring accurate readings and a longer lifespan.

Advantages of Stainless Steel Differential Pressure Gauges

stainless steel differential pressure gauge factories

2. Durability Stainless steel gauges are tough and resilient, able to withstand high pressure and extreme temperatures, making them ideal for varied industrial environments.

3. Accuracy High-quality stainless steel differential pressure gauges offer exceptional accuracy, ensuring that operators receive precise data for effective decision-making.

4. Low Maintenance Given their robust nature, these gauges require minimal maintenance, leading to lower operational costs over time.

5. Versatility With various designs and specifications available, stainless steel differential pressure gauges can be tailored to meet the needs of specific applications, whether in water treatment facilities, heating systems, or petrochemical plants.

Industrial Applications

Stainless steel differential pressure gauges find applications across various industries. In the oil and gas sector, they are used to monitor pressure drops across filters and separators, ensuring optimal performance and safety. In HVAC applications, these gauges help regulate airflow and enhance energy efficiency by assessing static pressure and airflow rates. Moreover, in pharmaceutical manufacturing, ensuring the integrity of clean environments is paramount, and differential pressure gauges play a key role in maintaining the necessary conditions by monitoring pressure differentials across sterile barriers.

Conclusion

In conclusion, stainless steel differential pressure gauges are indispensable tools in modern industrial practices. Their durability, resistance to corrosion, accuracy, and versatility make them suitable for various applications across different sectors. As industries continue to evolve and face new challenges, the significance of accurate pressure measurement remains paramount. Investing in reliable differential pressure gauges not only enhances the efficiency of operations but also safeguards the integrity of systems, ultimately contributing to improved productivity and safety. As manufacturers recognize these benefits, the demand for stainless steel differential pressure gauges will undoubtedly continue to grow, defining their role as a critical component in the landscape of industrial instrumentation.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025