Dec . 14, 2024 01:23 Back to list

stainless steel differential pressure gauge manufacturer

Stainless Steel Differential Pressure Gauge Manufacturers An Overview

In various industrial applications, maintaining the accuracy and reliability of pressure measurements is essential for optimal performance and safety. Among the tools deployed for this purpose, stainless steel differential pressure gauges stand out due to their durability, resistance to corrosion, and precision. These gauges are designed to measure the difference in pressure between two points in a system, which is crucial in processes such as fluid dynamics, HVAC systems, and filtration processes. This article delves into the aspects associated with stainless steel differential pressure gauge manufacturers, highlighting their importance, the manufacturing process, and key suppliers in the market.

Understanding Differential Pressure Gauges

Differential pressure gauges are essential instruments in industries where understanding the flow of fluids (liquids or gases) is necessary. They measure the difference in pressure between an inlet and outlet point, allowing operators to assess the performance of various systems. This measurement helps ensure that processes are running efficiently and can also signal when maintenance or replacement is needed, particularly in filters or pumps.

The use of stainless steel in their design is particularly advantageous. Stainless steel is renowned for its strength, durability, and resistance to rust and corrosion, making it ideal for environments where chemical exposure is common. This resistance extends the lifespan of the gauges and reduces the need for frequent replacements or repairs.

The Manufacturing Process

Manufacturing stainless steel differential pressure gauges involves several stages, each critical in ensuring the final product meets industry standards for accuracy, reliability, and safety. Key steps in this process include

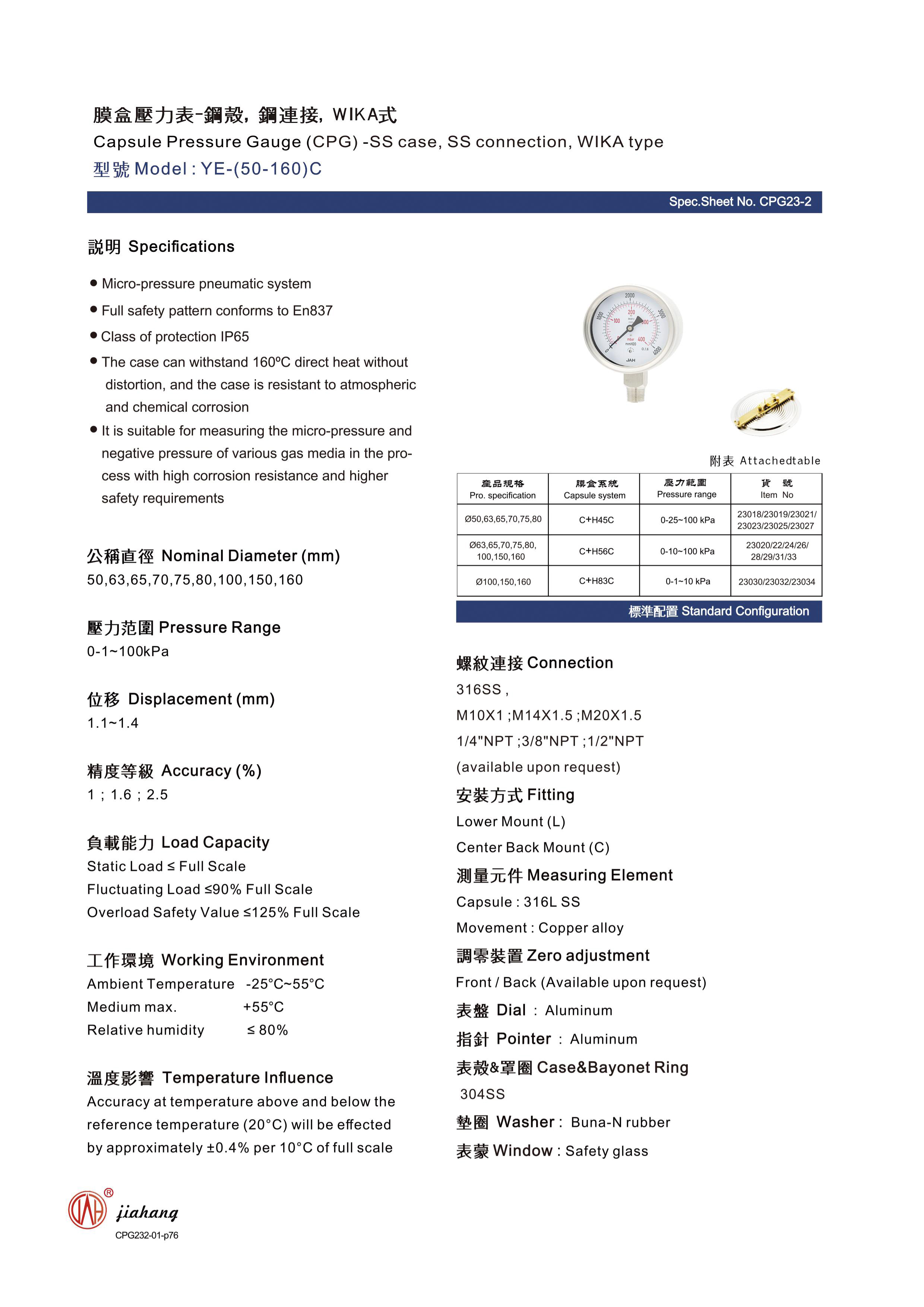

1. Material Selection Manufacturers select high-grade stainless steel that can withstand extreme temperatures and corrosive environments, such as 316 or 304 stainless steel.

2. Machining The selected stainless steel undergoes precise machining to create the various components of the gauge, including the housing, diaphragm, and internal mechanisms.

3. Assembly After machining, parts are assembled with careful attention to detail. This includes ensuring that seals are properly fitted to avoid leaks, and that all connections are secure.

4. Calibration Each gauge is calibrated to guarantee accuracy. This involves subjecting the gauge to known pressure environments to ensure it provides reliable readings.

stainless steel differential pressure gauge manufacturer

5. Testing Rigorous testing is performed to evaluate the performance of the gauges under different conditions, including temperature variations and pressure extremes.

6. Quality Control Finally, stringent quality control processes ensure that only products that meet predefined specifications are released to the market.

Key Manufacturers in the Market

Several manufacturers have established themselves as leaders in the production of stainless steel differential pressure gauges. Some of the notable names include

- Emerson Electric Co. Known for its technological advancements and reliability, Emerson offers a range of differential pressure gauges suitable for various applications in industries such as oil and gas, food and beverage, and pharmaceuticals.

- Siemens AG A global powerhouse in industrial automation, Siemens manufactures precision instruments, including stainless steel differential pressure gauges tailored for high-performance environments.

- Ashcroft With a history dating back to the 19th century, Ashcroft has developed a strong reputation for its pressure measurement products, emphasizing quality and long-lasting performance in its differential pressure gauge offerings.

- Wika Group Specializing in pressure and temperature measurement technology, Wika provides a variety of stainless steel gauges that cater to different industrial sectors, ensuring compliance with international standards.

- Omega Engineering Omega is well-known in the field of temperature and pressure measurement, providing a wide selection of differential pressure gauges made from robust materials.

Conclusion

Stainless steel differential pressure gauges are vital instruments in monitoring and maintaining the efficiency of various industrial processes. The manufacturers that produce these gauges play a crucial role in ensuring that they meet the rigorous demands of modern applications. By focusing on quality materials, precision manufacturing, and stringent testing, these companies contribute to advancements in industrial safety and efficiency. As industries continue to evolve, the need for reliable pressure measurement solutions will only grow, making the role of stainless steel differential pressure gauge manufacturers increasingly significant.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025