Jul . 26, 2024 03:23 Back to list

Top Manufacturers of Flush Diaphragm Pressure Gauges for Accurate Measurement Solutions

Understanding Flush Diaphragm Pressure Gauges and Their Manufacturers

In the realm of industrial instrumentation, accurate pressure measurement is crucial across various applications. One of the most significant innovations is the flush diaphragm pressure gauge, which offers unique advantages particularly in sanitary and viscous media applications. Understanding how these gauges work, their benefits, and what to consider when selecting a manufacturer is essential for any organization looking to enhance their measurement systems.

What is a Flush Diaphragm Pressure Gauge?

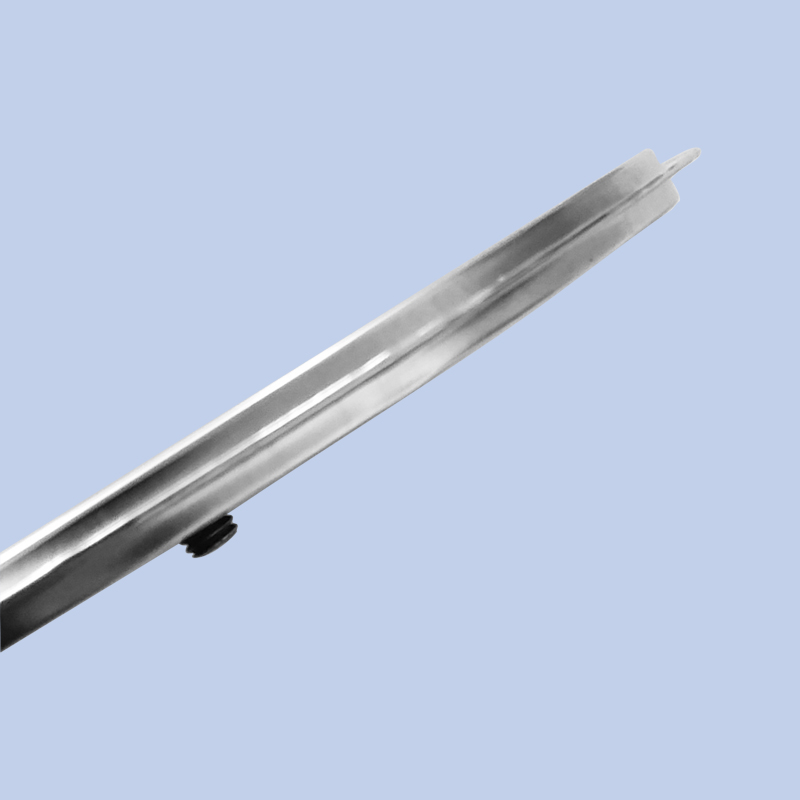

A flush diaphragm pressure gauge features a flat, non-vented diaphragm that is welded to the gauge housing. This design allows for the measurement of pressure in process conditions where the medium may be viscous, corrosive, or where the gauge's internals need to be protected from contamination. The flush diaphragm is often used in applications such as food processing, pharmaceuticals, and chemicals, where cleanliness and hygiene are paramount.

Advantages of Flush Diaphragm Pressure Gauges

1. Sanitary Design The flush diaphragm design eliminates the dead spaces that are common with traditional pressure gauges, making them easier to clean and sterilize. This is particularly important in industries such as food and beverage or pharmaceuticals where contamination can have severe consequences.

2. Reduced Clogging The flat diaphragm surface minimizes the risk of clogging, which can occur when viscous or slurry-like materials are involved. Traditional gauges may suffer from blockages, leading to inaccurate readings or even equipment failure.

3. Durability and Protection Flush diaphragm pressure gauges are robust and can withstand harsh conditions, including high pressure and temperature variations. Their design is less prone to damage from vibration or shock, which extends their service life.

4. Accurate Readings These gauges provide accurate and reliable pressure readings, even in dynamic processes, due to their direct contact with the process media. This leads to better process management and quality control.

flush diaphragm pressure gauge manufacturer

Choosing the Right Manufacturer

When selecting a manufacturer for flush diaphragm pressure gauges, there are several critical factors to consider

1. Experience and Reputation Look for a manufacturer with a proven track record in producing high-quality pressure gauges. Established companies often have years of experience and a reputation for reliability.

2. Customization Options Different industries may require specific gauges to meet unique needs. A good manufacturer will offer customization options to cater to the specific conditions of your application, be it material selection or gauge size.

3. Quality Standards Ensure that the manufacturer adheres to industry standards and certifications, such as ISO 9001, which can indicate a commitment to quality. This can be especially important in regulated industries.

4. Technical Support and Service Good manufacturers should provide adequate technical support and after-sales service. This includes assistance with installation, maintenance, and calibration to ensure that your gauges perform optimally over their lifespan.

5. Innovative Technology Look for manufacturers that employ the latest technologies and innovations in their products. Features such as digital displays, remote monitoring capabilities, and advanced sensors can enhance functionality and usability.

Conclusion

Flush diaphragm pressure gauges are indispensable tools in various industries due to their unique design and advantages. When selecting a manufacturer, it is crucial to consider their experience, customization capabilities, adherence to quality standards, support, and technological advancements. By investing in high-quality flush diaphragm pressure gauges, organizations can ensure accurate pressure measurements, enhance process efficiency, and maintain the highest standards of safety and cleanliness in their operations.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025