Jul . 26, 2024 03:28 Back to list

Understanding the Benefits and Applications of Diaphragm Sealed Pressure Gauges in Various Industries

Diaphragm-Sealed Pressure Gauges An Essential Tool for Accurate Measurements

In various industrial applications, accurate pressure measurement is vital for maintaining the safety, efficiency, and integrity of systems. One of the most effective solutions for measuring pressure in challenging environments is the diaphragm-sealed pressure gauge. These gauges are specifically designed to provide precise readings even in the presence of corrosive fluids, high temperatures, or extreme pressures.

Understanding Diaphragm-Sealed Pressure Gauges

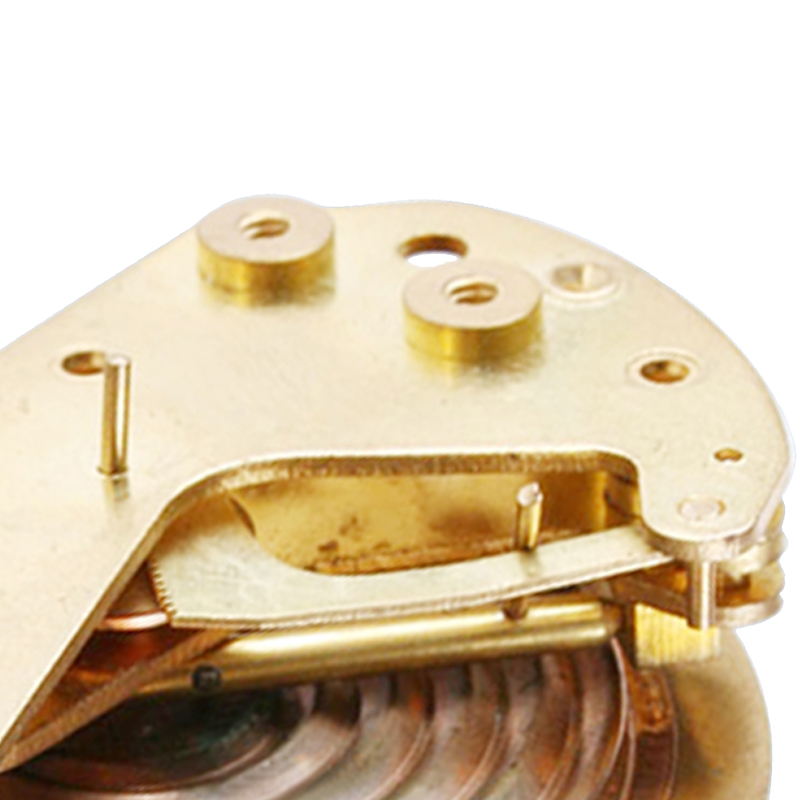

Diaphragm-sealed pressure gauges utilize a flexible diaphragm to separate the measuring element from the process fluid. This design is crucial in applications where the fluid is not only corrosive but also potentially damaging to traditional mechanical components. By isolating the pressure sensing mechanism from the fluid, diaphragm-sealed gauges protect the integrity of the measurement system, ensuring longevity and reliability.

The diaphragm acts as a barrier, deforming under pressure, which in turn transmits that pressure signal to the gauge's internal mechanisms. This design allows for high accuracy in pressure readings while minimizing the risk of contamination and damage to sensitive components. Such gauges are commonly used in industries like oil and gas, chemicals, pharmaceuticals, and food processing.

Benefits of Using Diaphragm-Sealed Gauges

1. Protection Against Corrosive Fluids The primary advantage of diaphragm-sealed pressure gauges is their ability to withstand corrosive substances. The barrier created by the diaphragm prevents direct contact between the pressure fluid and the gauge's internal components, which minimizes wear and degradation.

2. Enhanced Durability Because diaphragm-sealed gauges can be designed to handle high pressures and extreme temperatures, they are often more durable than standard gauges. This durability means less frequent replacements and lower overall maintenance costs.

diaphragm sealed pressure gauges service

3. Accuracy and Reliability These gauges typically provide highly accurate readings, crucial for processes that require precision. The diaphragm’s responsiveness ensures that pressure fluctuations are accurately captured, leading to reliable data for monitoring and control purposes.

4. Versatile Applications Diaphragm-sealed pressure gauges are highly versatile and can be used in a range of applications. Whether in a petrochemical plant or a food processing facility, these gauges can be tailored to suit the specific needs of the operation, including custom materials and seal types.

5. Ease of Installation and Maintenance Most diaphragm-sealed gauges can be easily installed and do not require extensive calibration. Their design allows for straightforward maintenance, ensuring that users can maintain accuracy with minimal downtime.

Applications of Diaphragm-Sealed Pressure Gauges

Diaphragm-sealed pressure gauges are employed in diverse applications

- Oil and Gas Industry In oil extraction and processing, these gauges monitor pressures in pipelines and storage tanks, where corrosive substances can be prevalent. - Chemical Manufacturing The pharmaceutical sector often uses these gauges to monitor the pressure of gases and liquids in reactors and storage vessels, where contamination must be avoided at all costs. - Food and Beverage Processing Here, hygiene is paramount, and these gauges help ensure that processes remain uncontaminated while still providing accurate pressure readings.

Conclusion

Diaphragm-sealed pressure gauges provide a robust and accurate solution for measuring pressure in challenging environments. With their ability to protect against corrosive fluids and provide reliable readings, they are an essential tool in numerous industrial applications. By investing in quality diaphragm-sealed gauges, industries can enhance operational efficiency, ensure product quality, and uphold safety standards in their processes. As technology continues to evolve, we can expect further advancements in these gauges, driving even higher levels of precision and durability in pressure measurement.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025