Sep . 10, 2024 10:18 Back to list

wika differential pressure gauge with diaphragm seal jah

Understanding Wika Differential Pressure Gauges with Diaphragm Seal

Wika, a prominent manufacturer in the field of measurement and control technology, offers a range of advanced differential pressure gauges designed for precise fluid measurement. Among their robust product line, Wika’s differential pressure gauge with diaphragm seal stands out due to its innovative design aimed at ensuring both accuracy and reliability in challenging applications.

Differential pressure gauges are essential instruments that measure the difference in pressure between two points in a system. These instruments are crucial in various industries, including chemical processing, pharmaceuticals, food and beverage, and oil and gas, where monitoring pressure differences is critical for safe and efficient operations. The diaphragm seal specifically enhances the gauge’s functionality by isolating the pressure measuring element from the process media, thereby protecting it from potentially corrosive or viscous fluids.

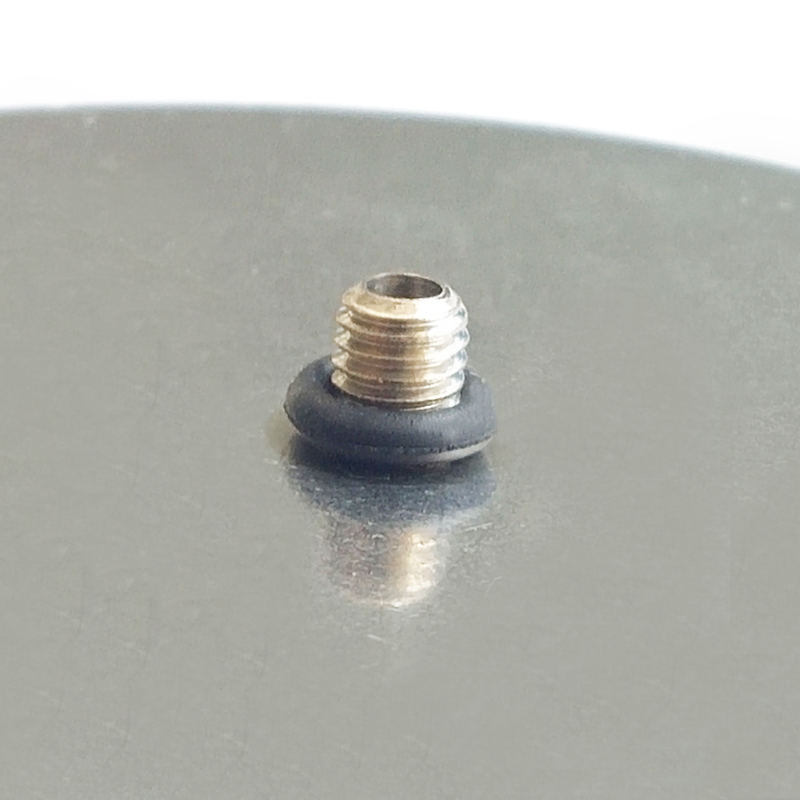

The diaphragm seal mechanism works by using a flexible diaphragm that separates the pressure sensing element from the process fluid. This design not only prevents clogging and corrosion but also allows for accurate readings in harsh environments. Wika’s diaphragm seals can be made from various materials, including stainless steel, to cater to different media types and temperatures. This adaptability ensures that users can find a suitable solution for their specific application needs.

wika differential pressure gauge with diaphragm seal jah

Another key feature of Wika differential pressure gauges is their built-in temperature compensation, which helps maintain accuracy in fluctuating temperatures. This is particularly important in processes where temperature variations can affect pressure readings. The easy readability of Wika gauges, often equipped with analog dials or digital displays, further enhances their usability in both manual monitoring and automated systems.

Moreover, these gauges can be equipped with options for electrical outputs, enabling integration with modern control systems for automated monitoring and data logging. This capability is vital for industries striving for optimal efficiency and precise process control.

In summary, Wika’s differential pressure gauges with diaphragm seals offer a reliable and efficient solution for measuring pressure differences in a wide variety of industrial applications. Their innovative design protects the measuring element, ensuring longevity and accuracy while accommodating the unique challenges presented by different media. For industries where precision and durability are paramount, investing in Wika’s differential pressure gauges translates to safer operations and improved process efficiency.

-

Digital Pressure Gauge RS Components for Semiconductor & Chip Industries

NewsMay.23,2025

-

Industrial Differential Pressure Gauges Global Supplier & Pricelist

NewsMay.23,2025

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025