Sep . 08, 2024 03:55 Back to list

wika sanitary diaphragm pressure gauge supplier

Understanding Wika Sanitary Diaphragm Pressure Gauges

In various industrial applications, precise measurement of pressure is crucial for ensuring safety and efficiency. Among the many tools available for this purpose, the Wika sanitary diaphragm pressure gauge stands out for its reliability and accuracy, particularly in sanitary and hygienic environments.

What is a Diaphragm Pressure Gauge?

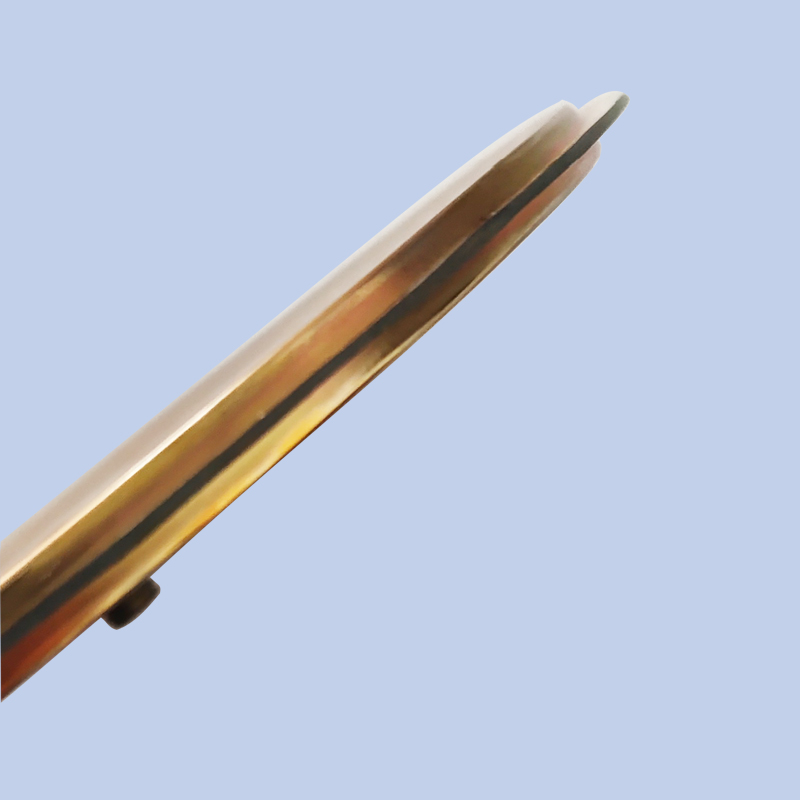

A diaphragm pressure gauge is a type of pressure measuring instrument that uses a flexible diaphragm to sense pressure changes. When fluid applies pressure to the diaphragm, it bends, and this deflection is converted into a readable measurement. For sanitary applications, these gauges are specially designed to prevent contamination and ensure that they meet stringent cleanliness standards.

Features of Wika Sanitary Diaphragm Pressure Gauges

Wika, a leading manufacturer in pressure measurement technology, offers a range of sanitary diaphragm pressure gauges that are ideal for the food, pharmaceutical, and biotechnology industries. Some key features include

1. Hygienic Design Wika’s sanitary gauges are designed with smooth surfaces and minimal crevices, which prevents the buildup of bacteria and other contaminants. They comply with standards such as 3A, ensuring they are suitable for use in health-sensitive environments.

2. Quality Materials The materials used in Wika gauges, such as stainless steel, are chosen for their corrosion resistance and durability. This ensures the gauges can withstand harsh cleaning agents and extreme conditions often found in processing plants.

3. Accuracy and Reliability Wika is known for its high standards in manufacturing, providing pressure gauges that offer superior accuracy. This is particularly important in industries where precision is necessary for product quality and safety.

wika sanitary diaphragm pressure gauge supplier

4. Range of Options The Wika sanitary diaphragm pressure gauge line includes various ranges and designs to suit different applications. Whether it’s measuring the pressure of gases, liquids, or slurries, Wika provides tailored solutions to meet specific requirements.

5. User-Friendly Design Many models come equipped with easy-to-read dials and available digital displays, allowing for quick and accurate readings. Additionally, features like adjustable zero and dampening options help operators take measurements more effectively.

Applications in Industry

Wika sanitary diaphragm pressure gauges are extensively used in several industries

- Food and Beverage Ensuring process integrity and safety in food production requires reliable pressure measurement. Wika gauges help maintain quality control.

- Pharmaceuticals In the pharmaceutical industry, maintaining sterile environments is paramount. These gauges assist in ensuring that processes operate within specified pressure ranges.

- Biotechnology Pressure measurement in bioreactors is critical for optimal growth conditions. Wika gauges provide the necessary data to enhance production efficiency.

Conclusion

Choosing a Wika sanitary diaphragm pressure gauge comes with the assurance of quality, safety, and reliability. With their specialized design for hygienic applications, they are indispensable in industries that prioritize cleanliness and precision. For those in need of dependable pressure measurement solutions, Wika offers a comprehensive range of products tailored to meet the demands of modern industrial processes. Whether you are in food production, pharmaceuticals, or biotechnology, investing in Wika's innovative designs will enhance your operational efficiency and safety standards.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025